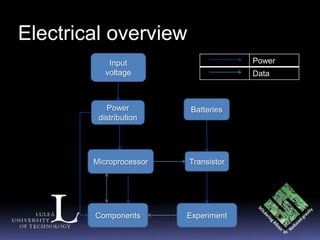

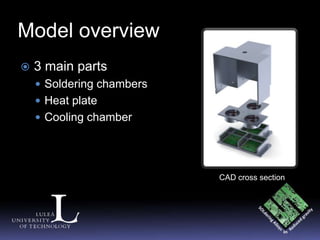

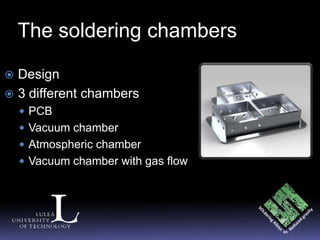

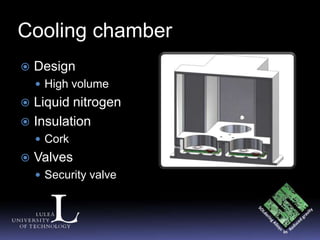

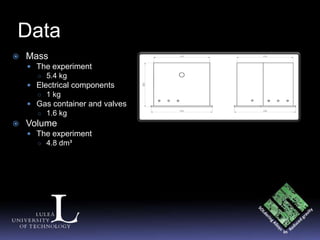

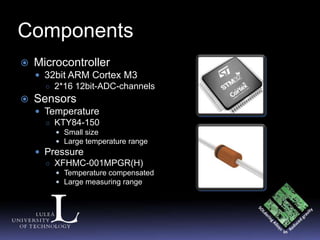

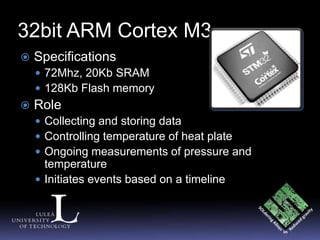

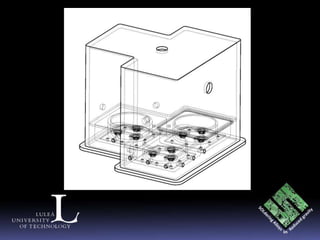

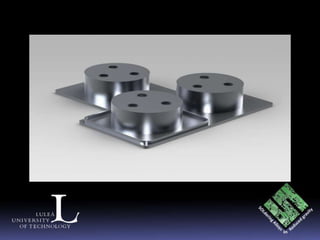

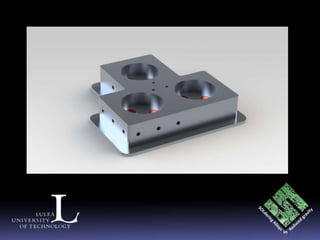

The document describes a proposed experiment to study soldering in reduced gravity. It will test soldering 9 samples in different environments: atmosphere, vacuum, and vacuum with gas flow. Sensors will measure temperature and pressure during melting and cooling. A microcontroller will control heating and collect data. Batteries will power heating, and valves will regulate gas flow. Results may help repair components in space.