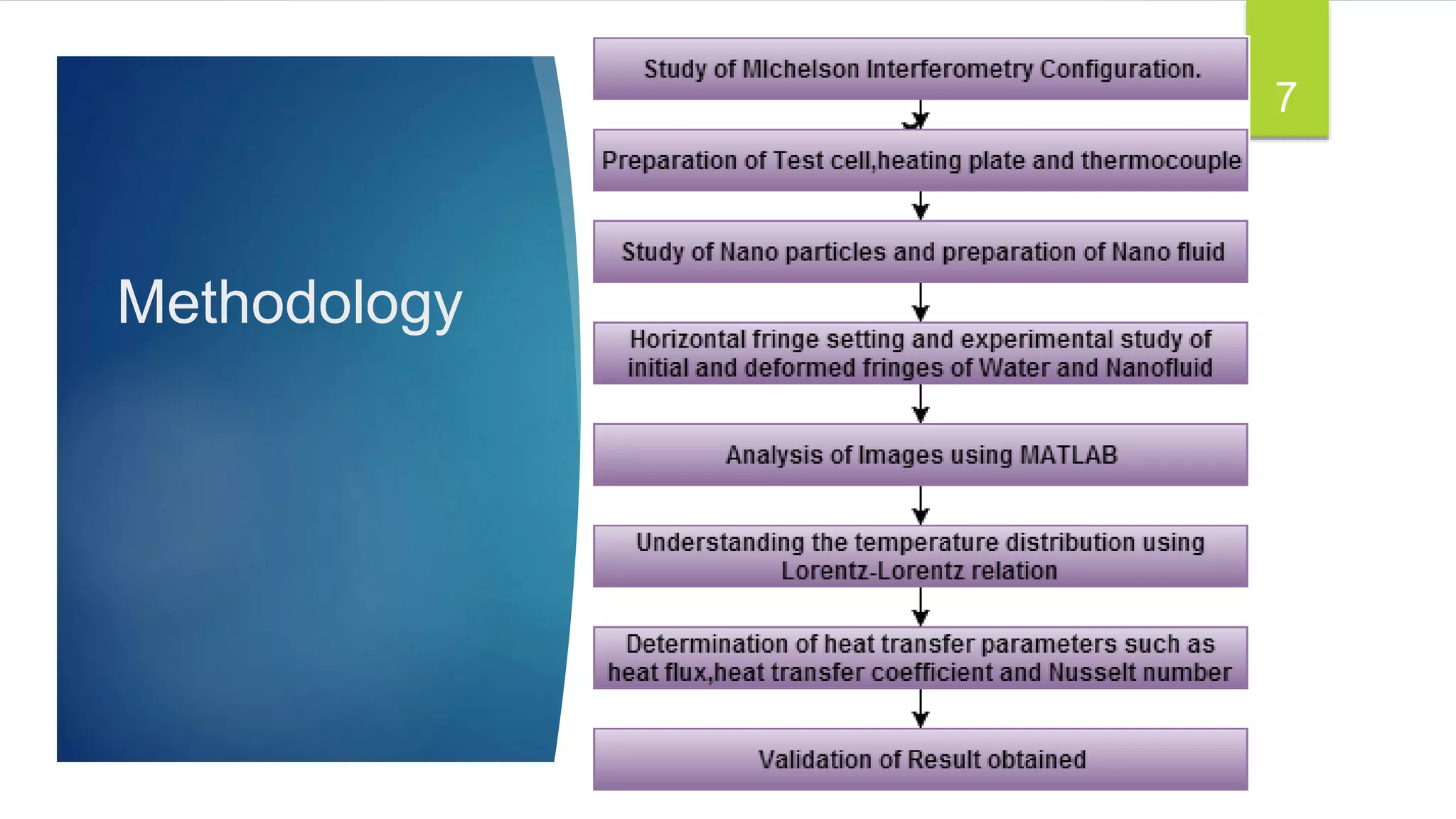

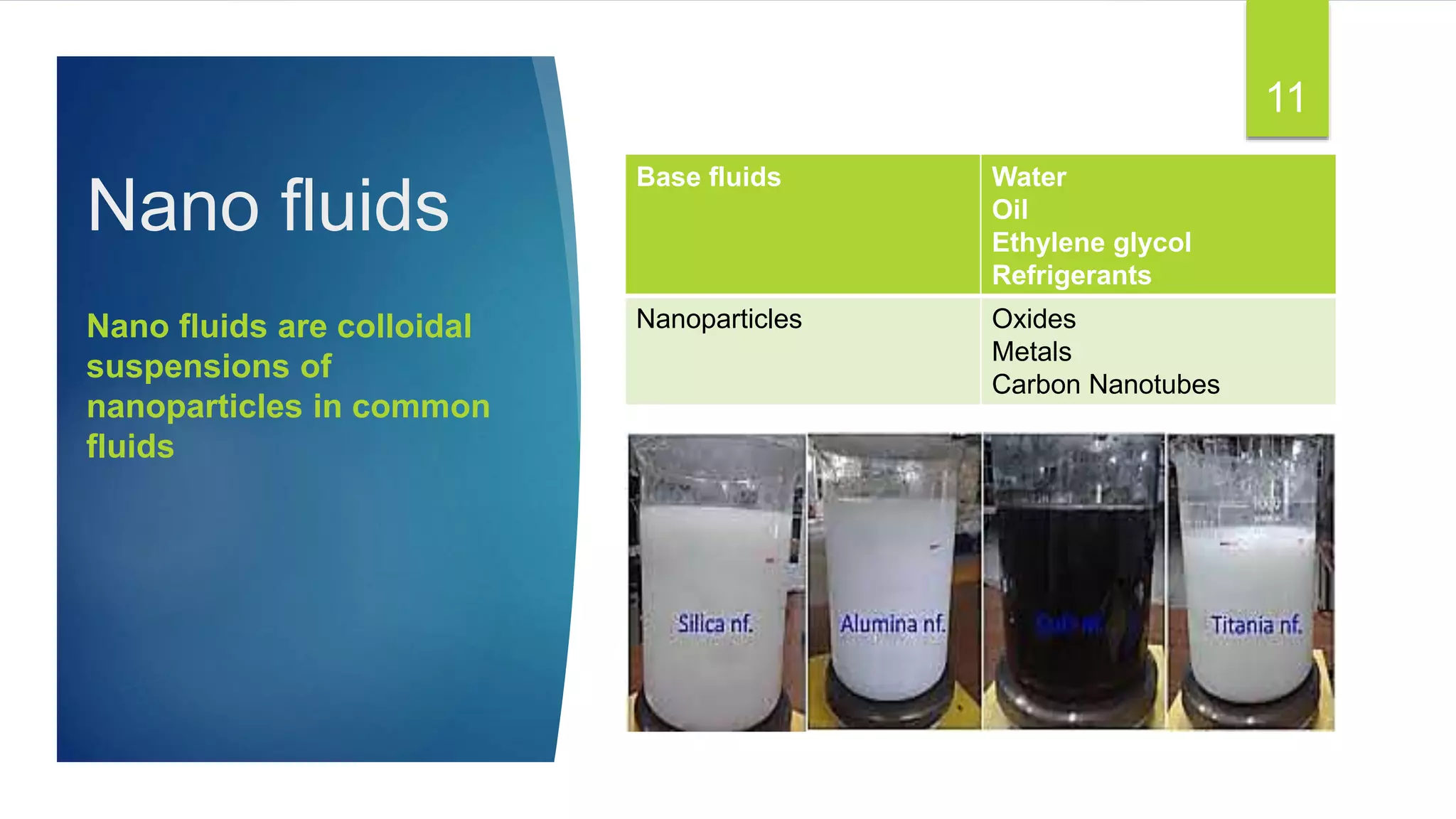

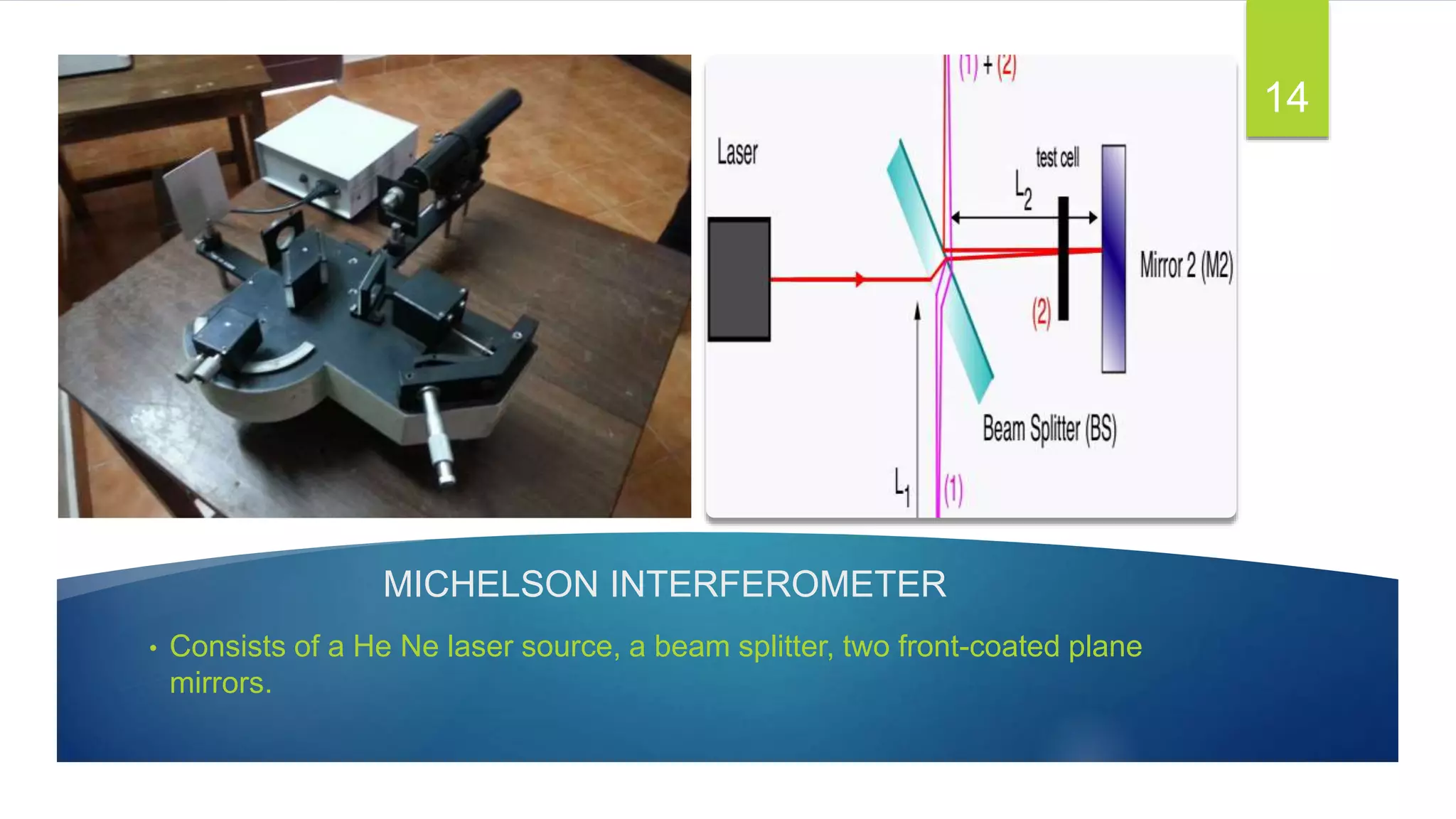

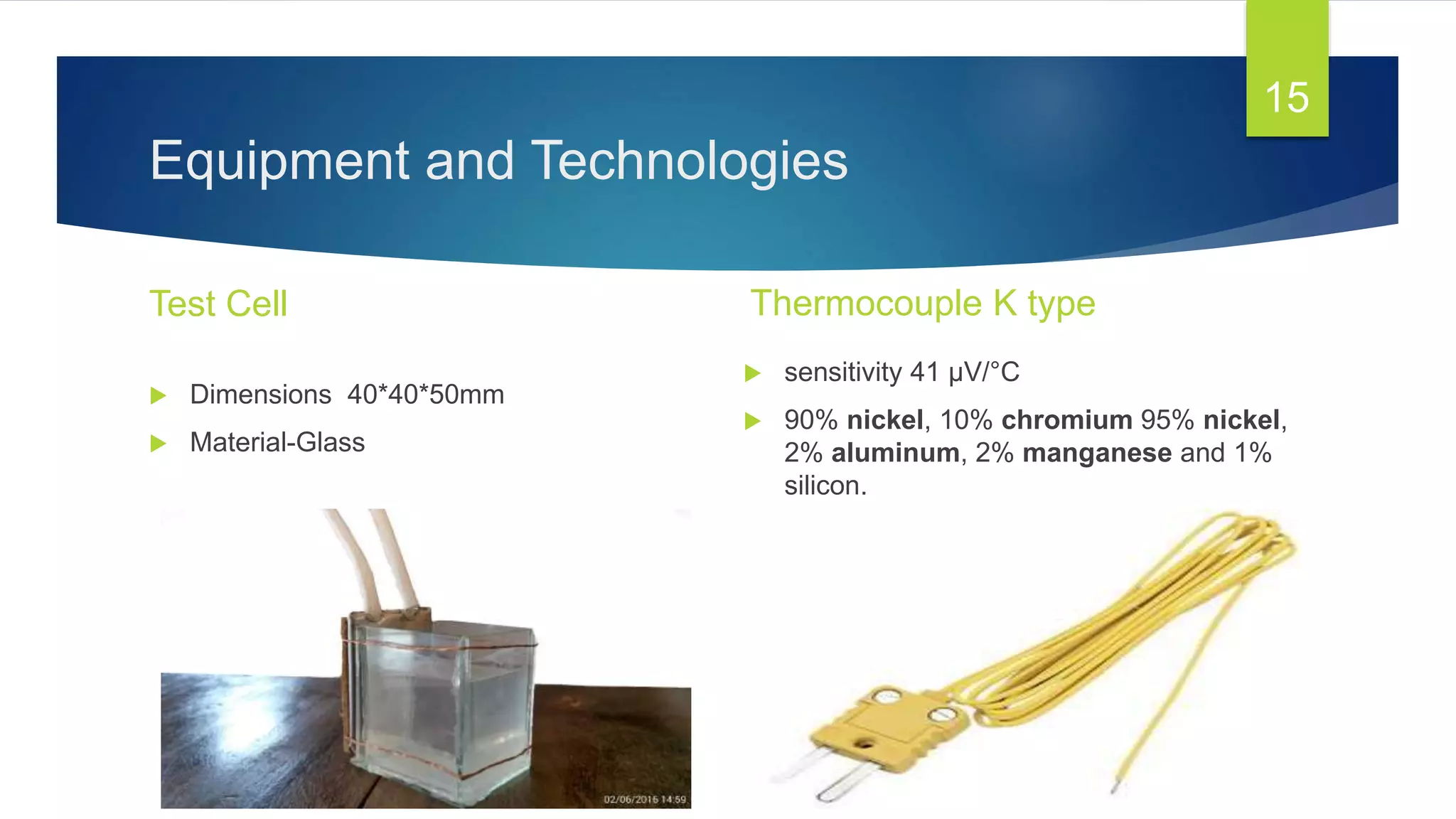

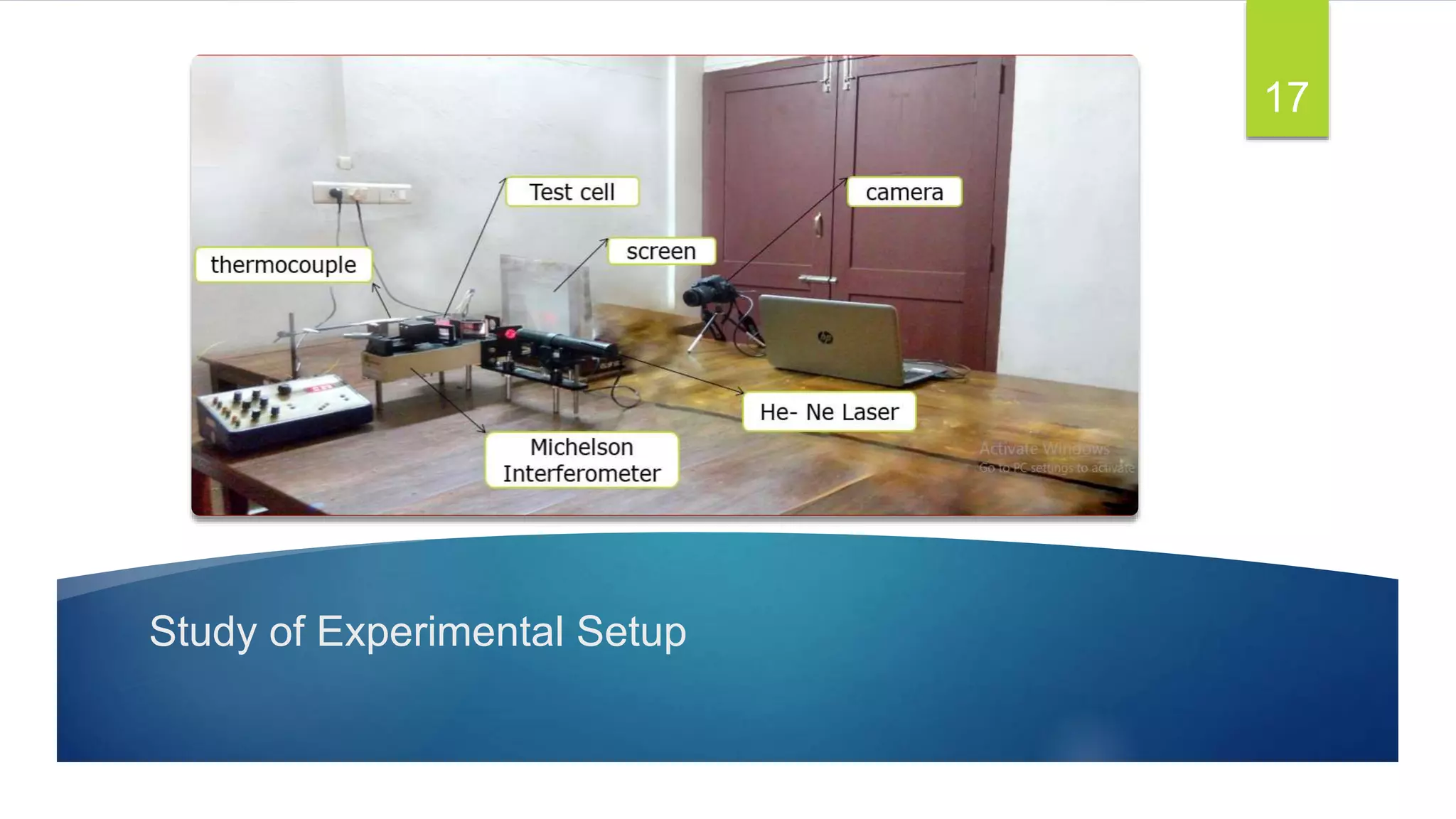

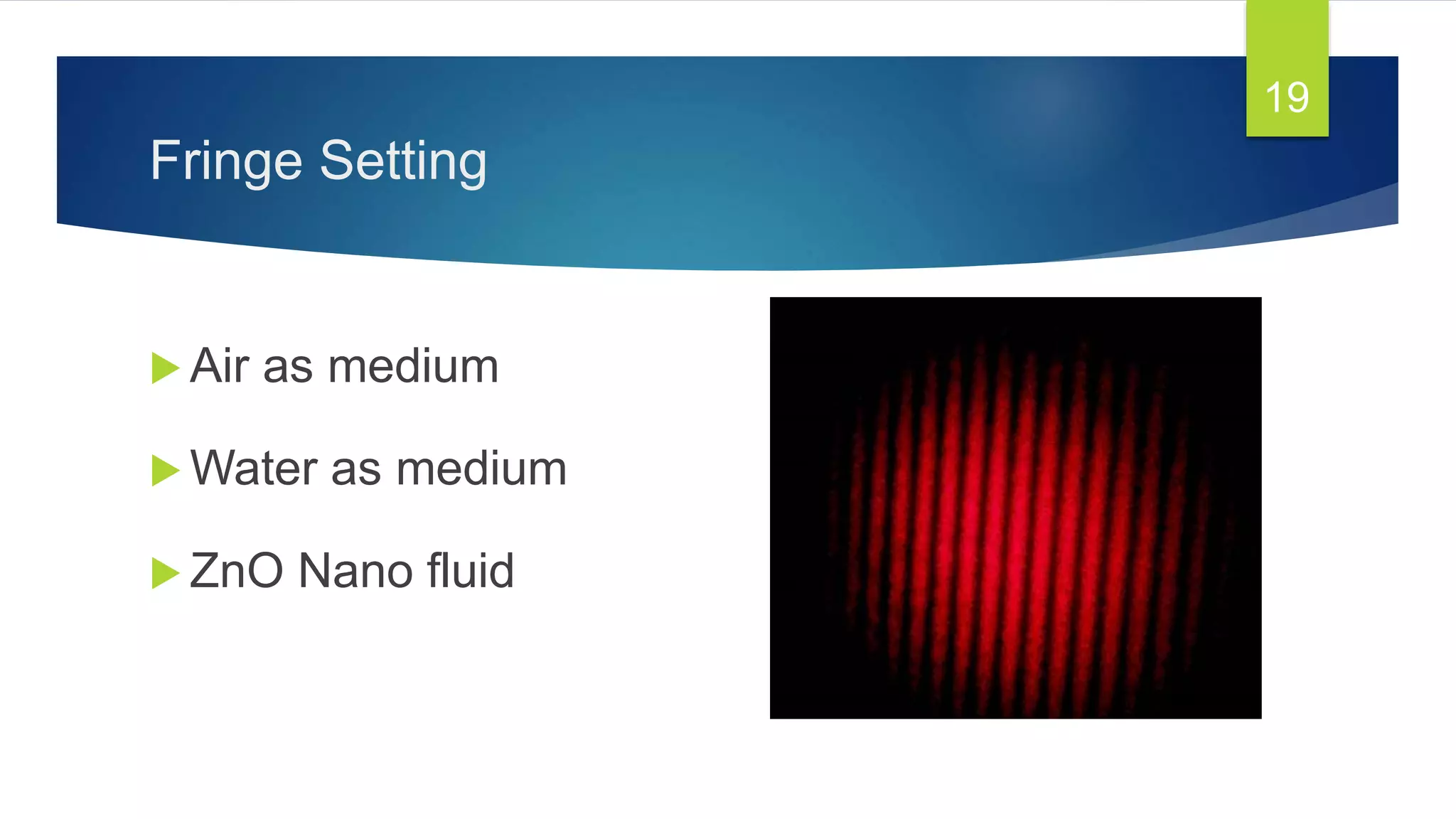

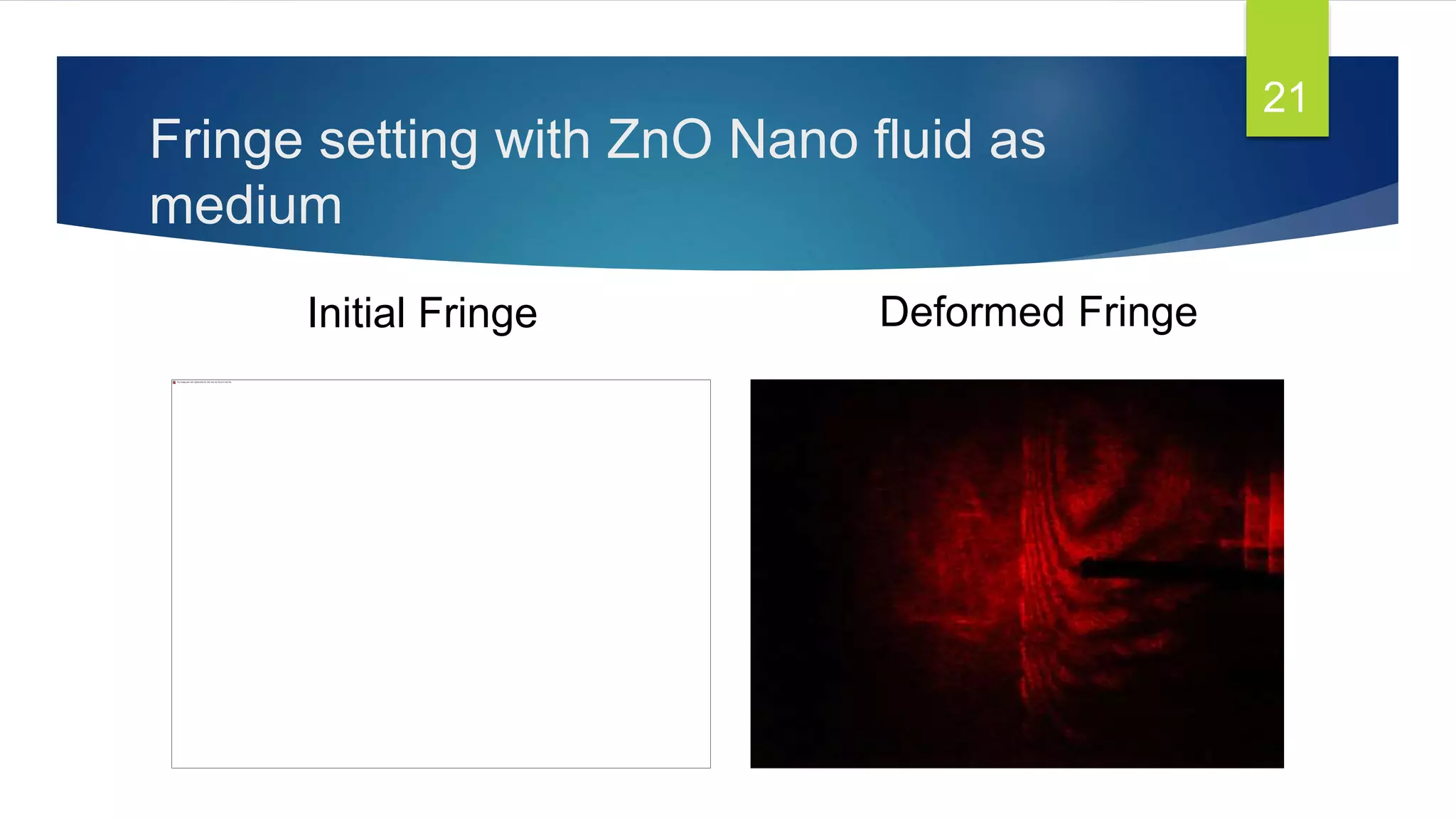

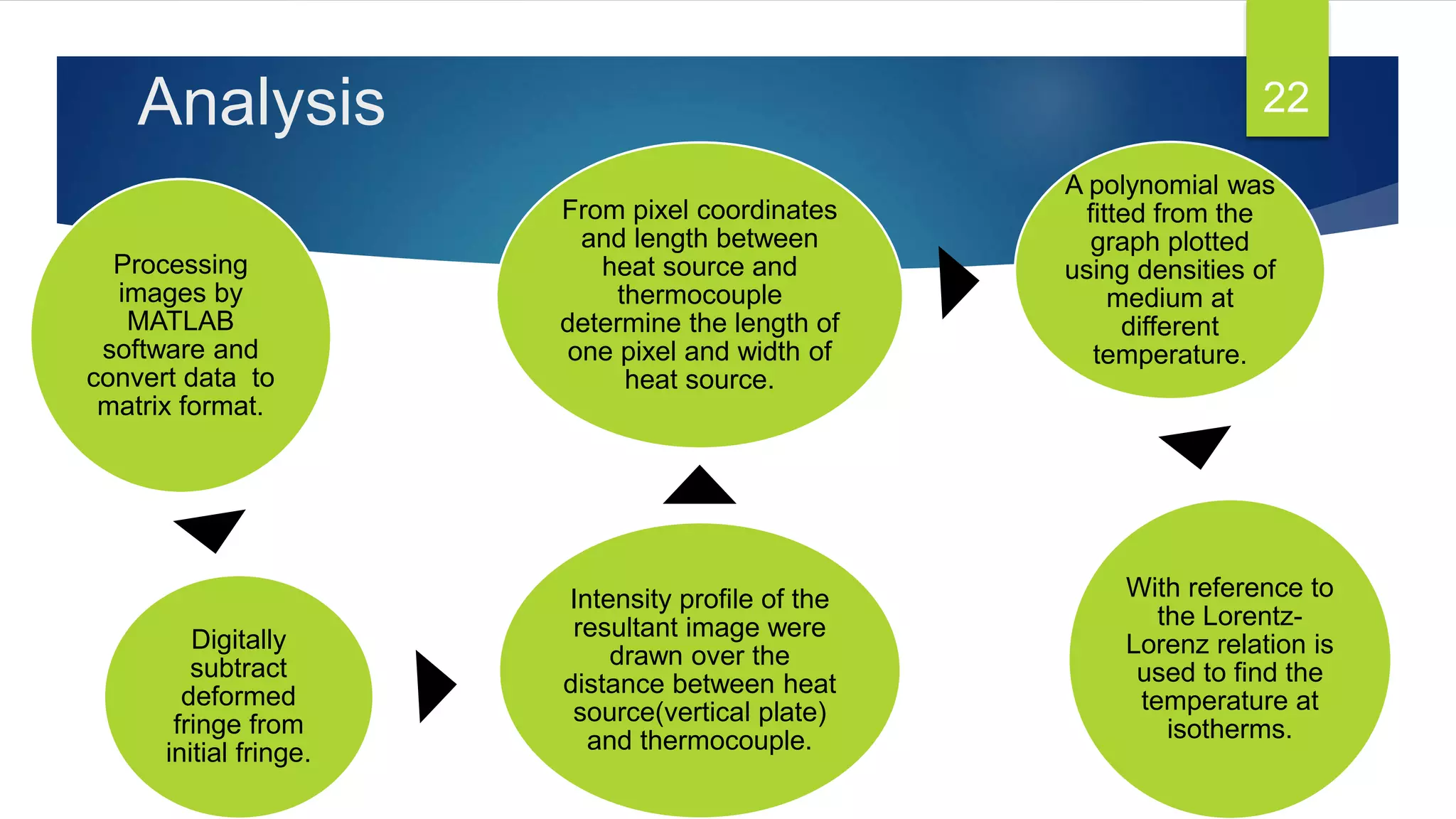

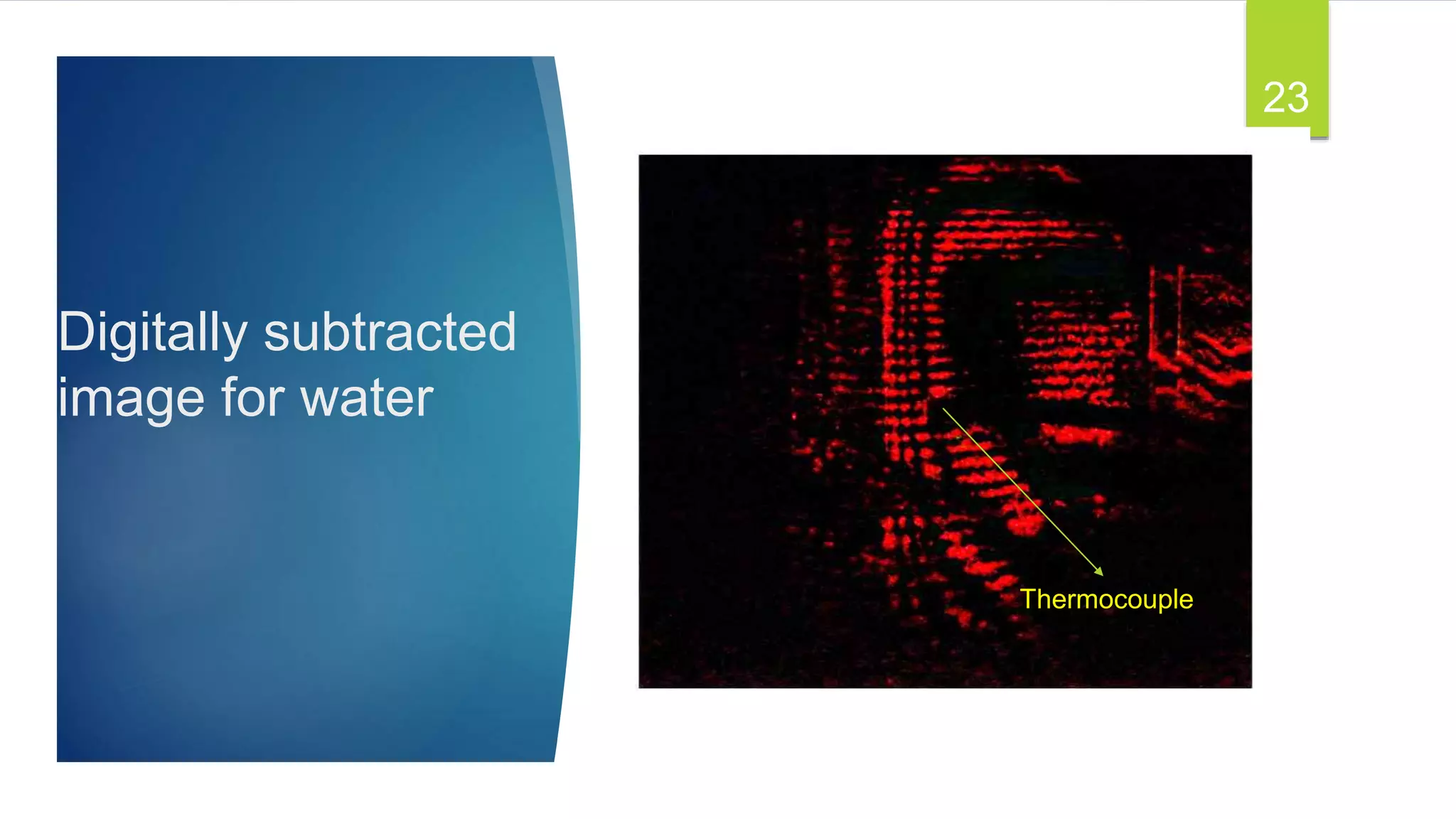

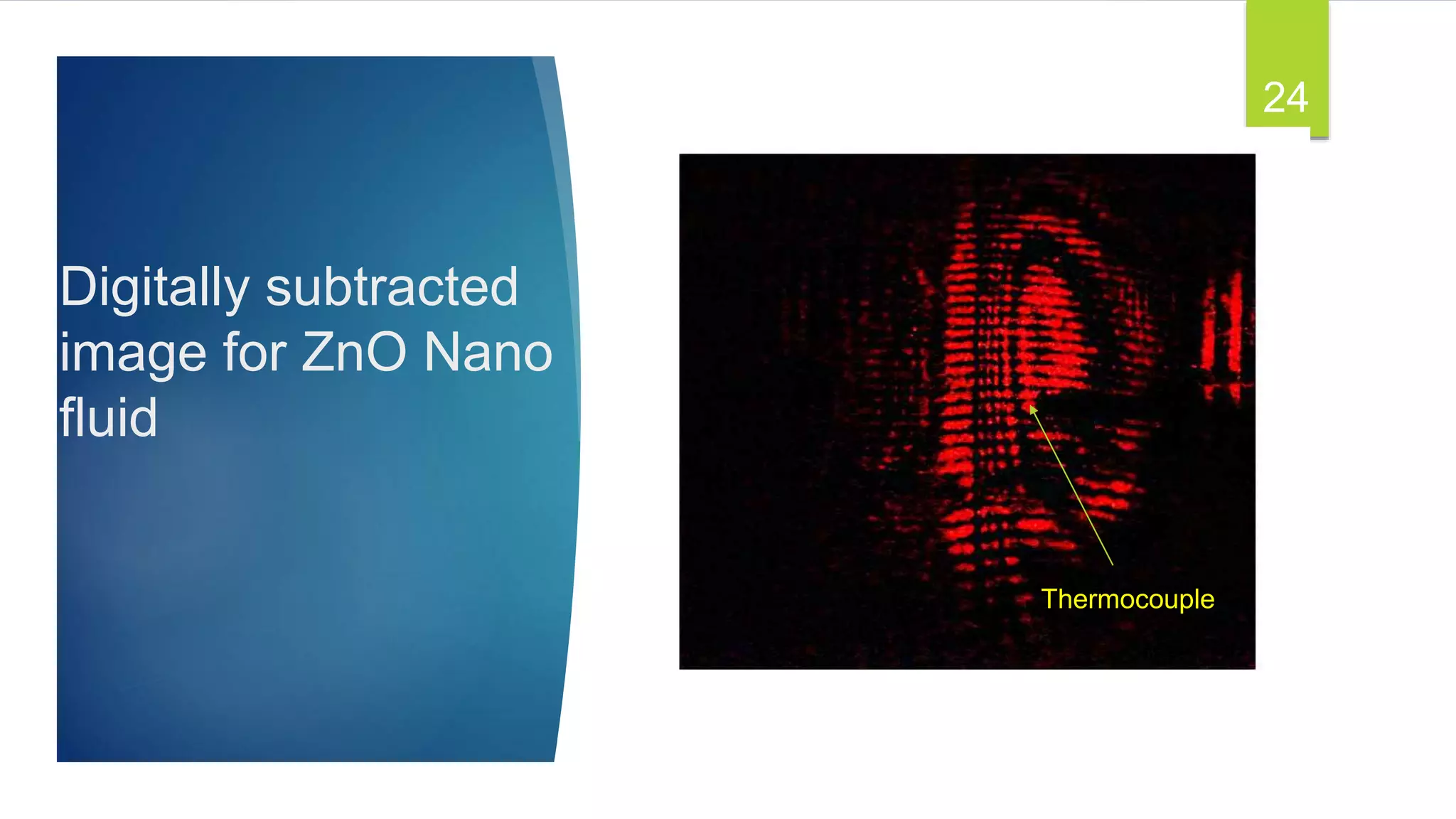

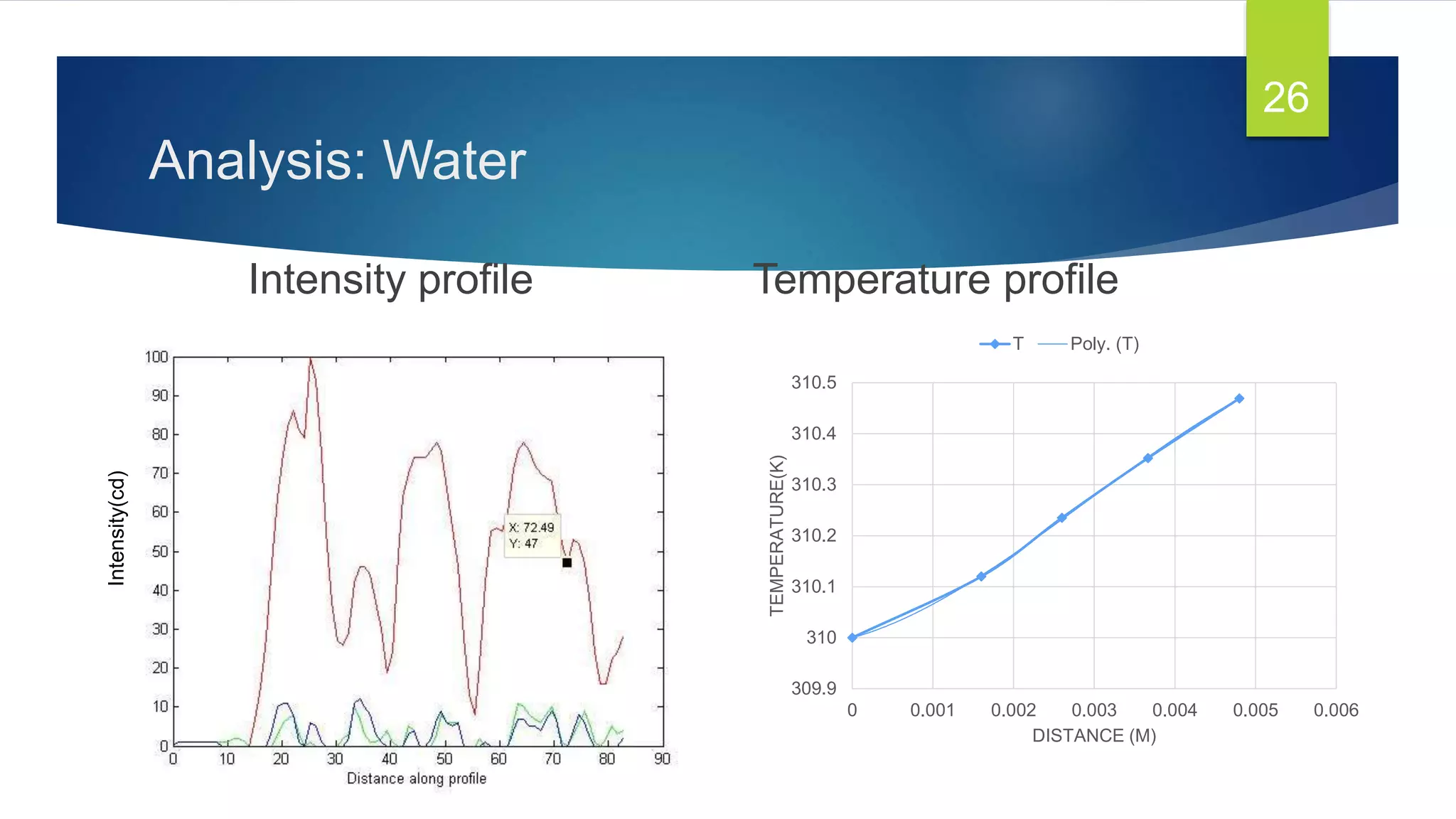

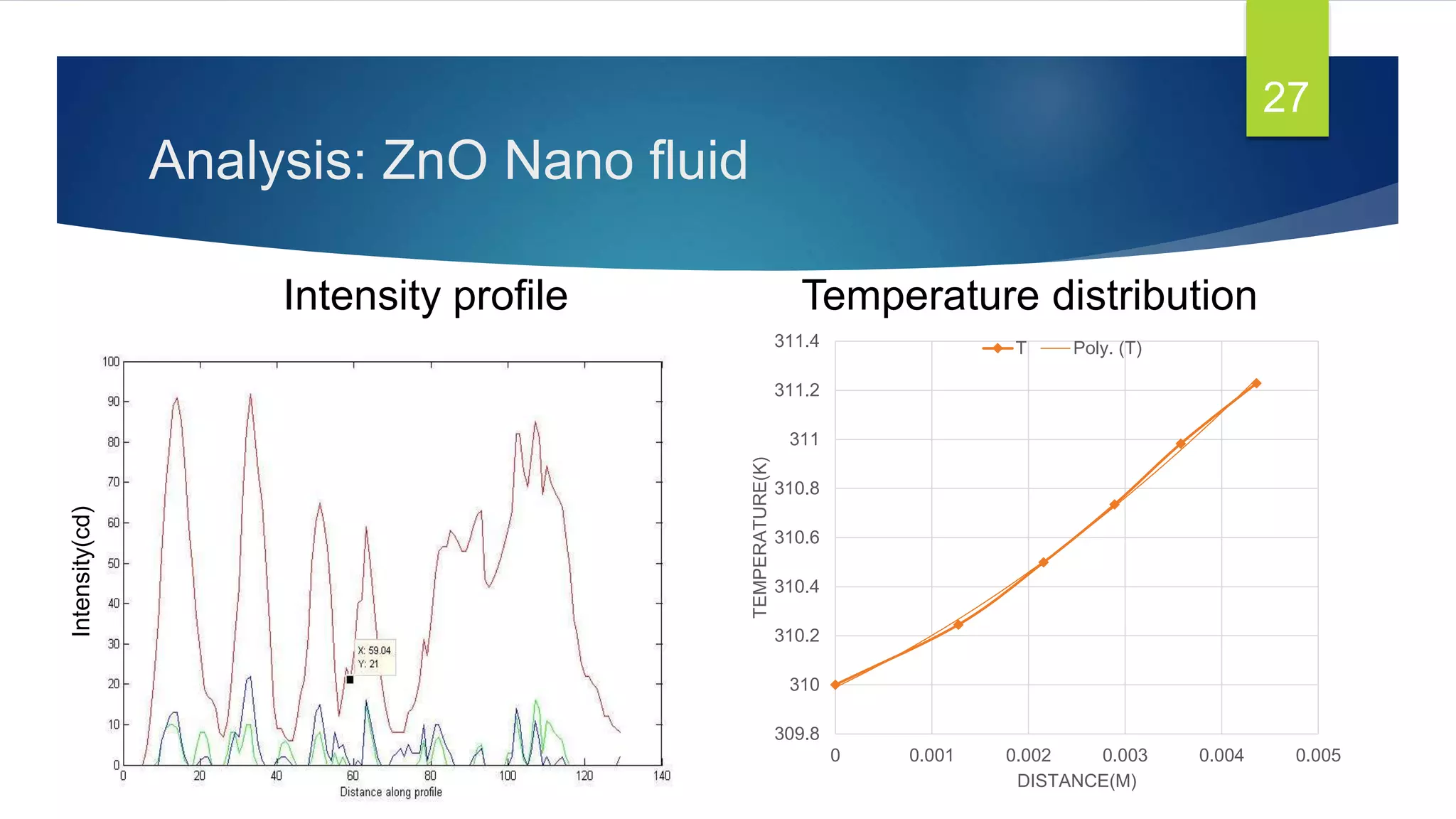

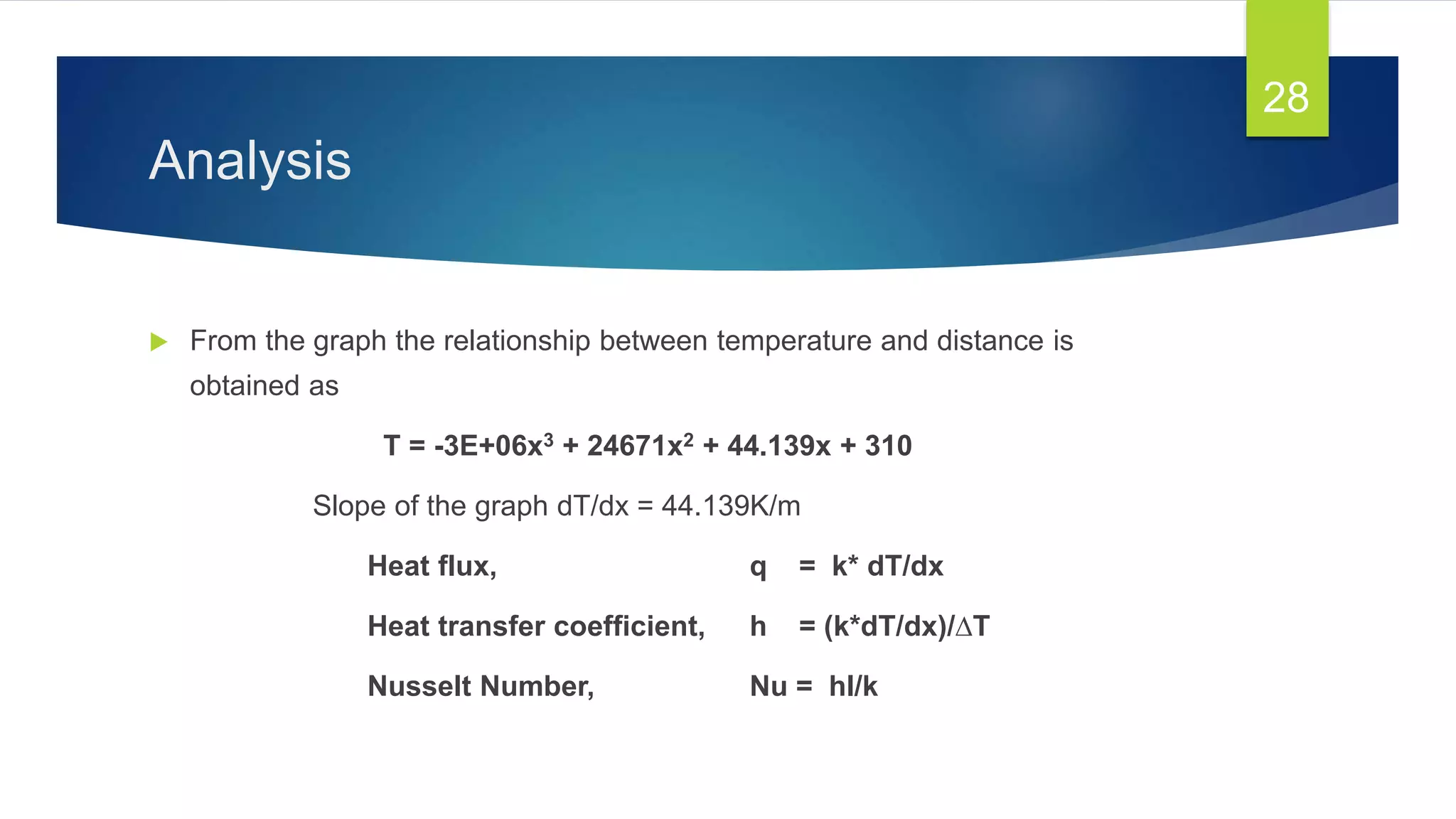

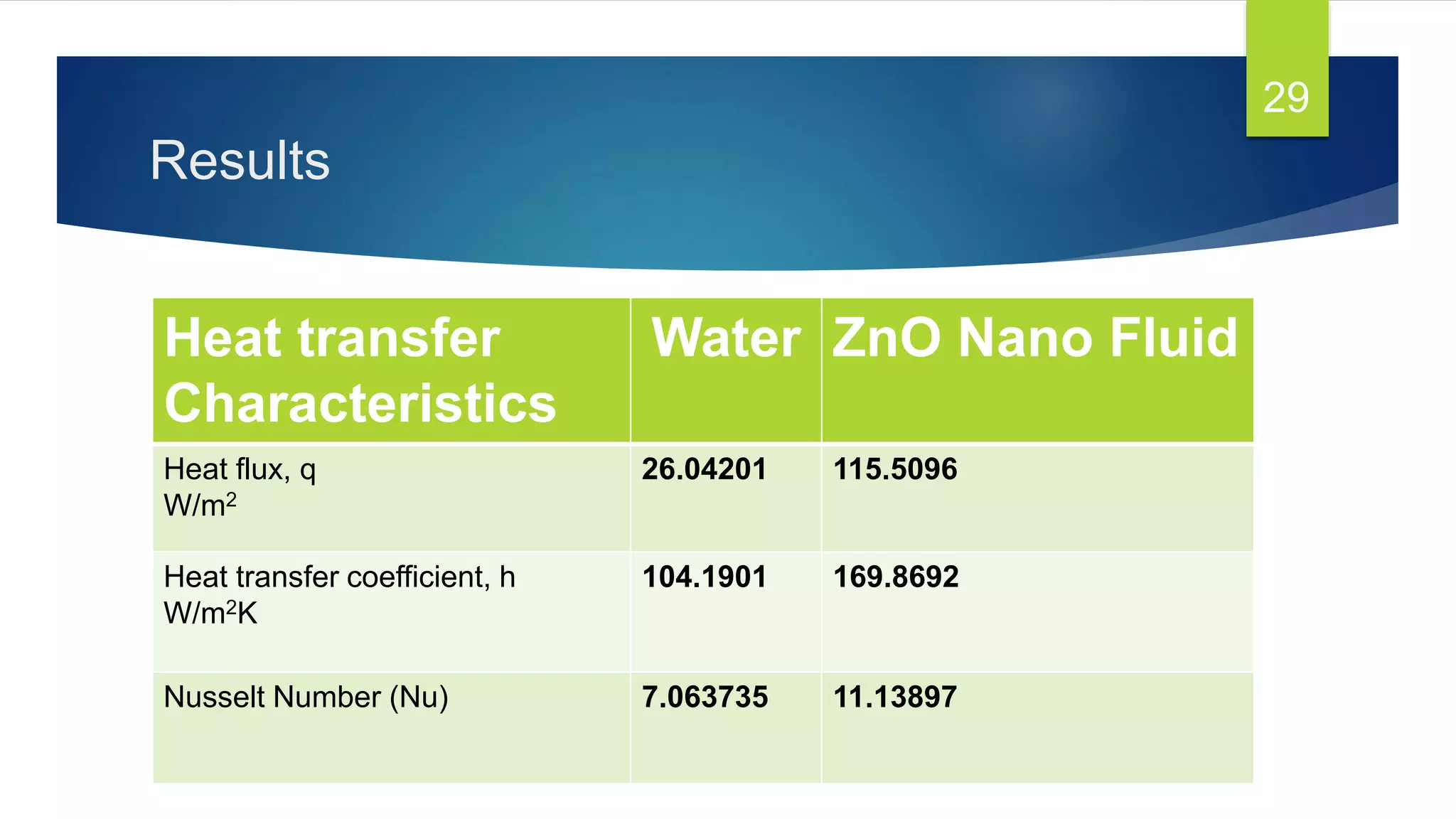

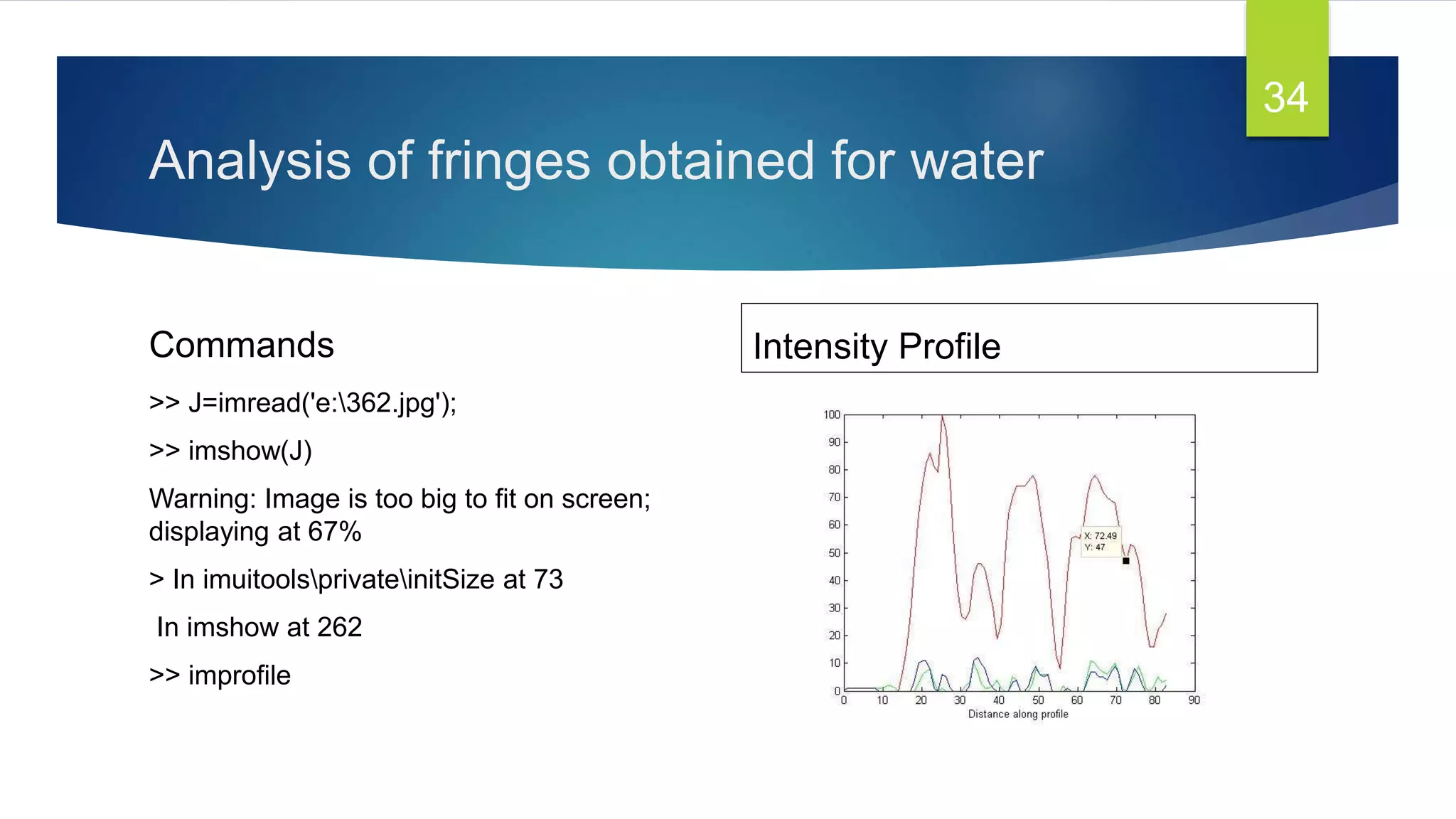

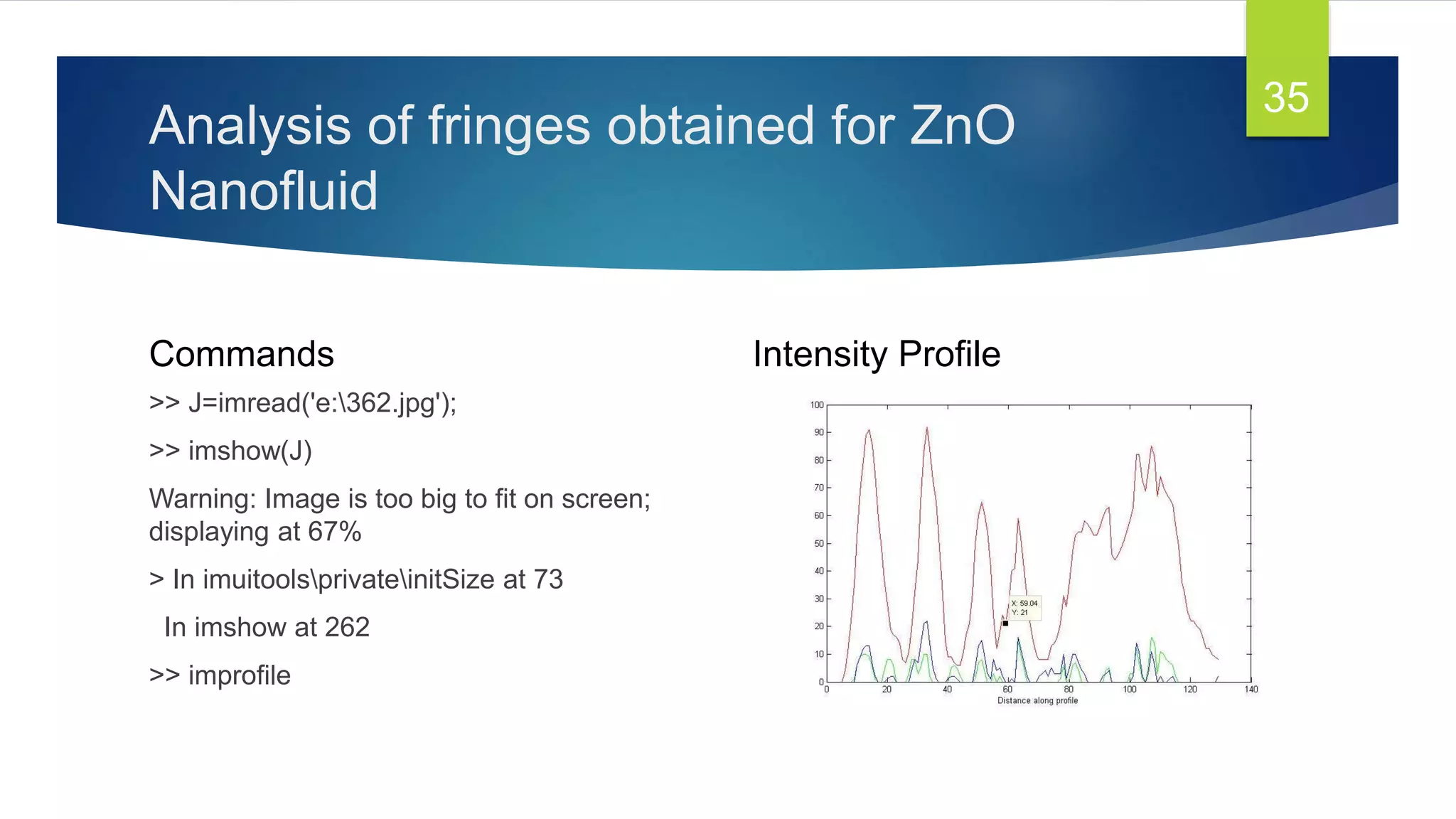

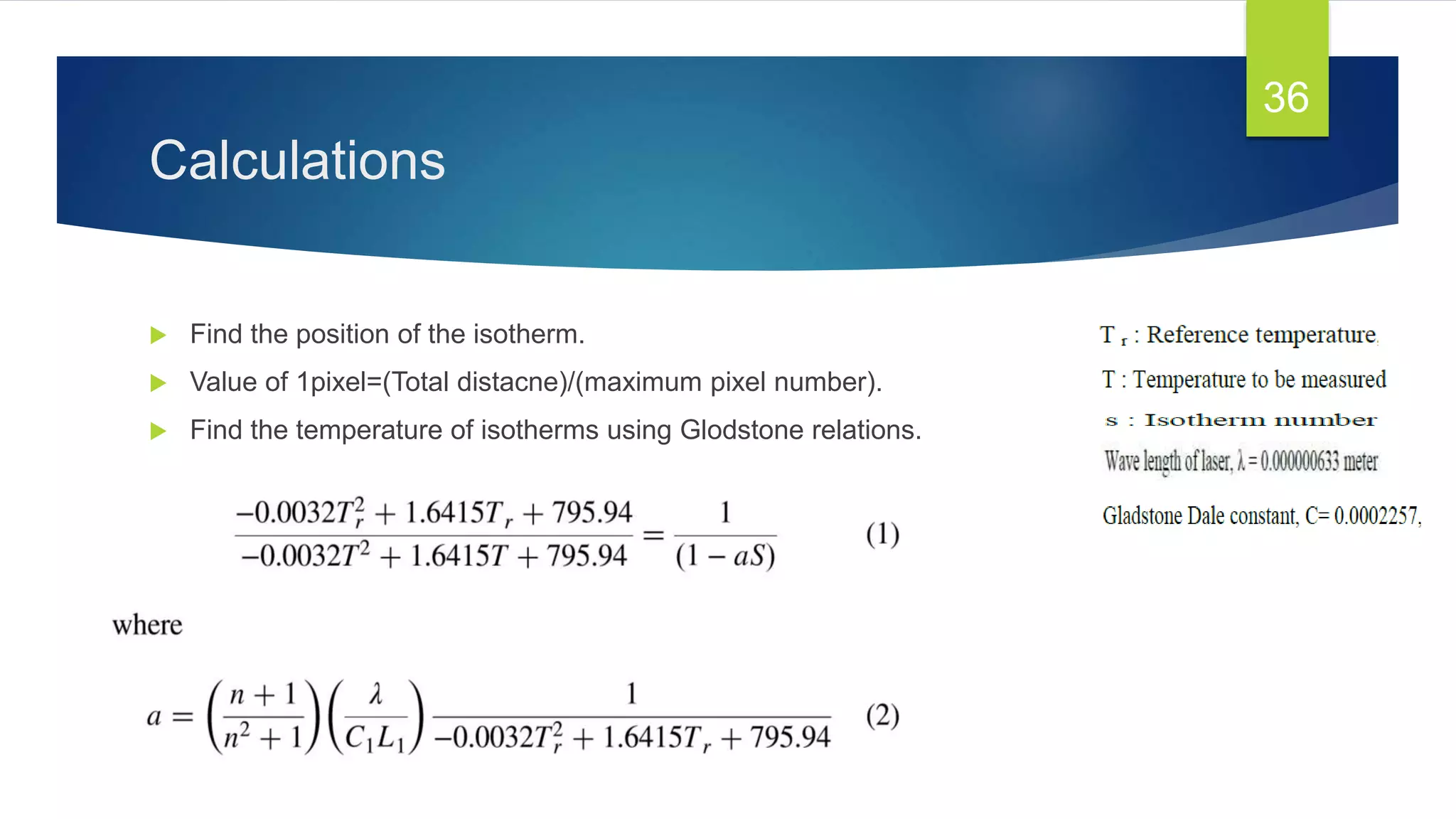

The document outlines a project on investigating heat transfer properties of ZnO nanofluids using Michelson interferometry. It details the project's objectives, methodology, equipment used, and results indicating that ZnO nanofluids exhibit superior heat transfer characteristics compared to water. The findings emphasize the importance of understanding nanofluids for applications in energy-efficient heat transfer technologies.