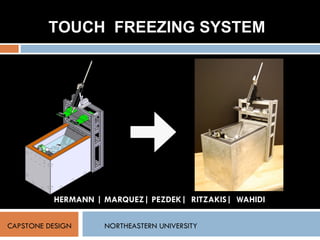

The document describes the design and functionality of a touch freezing system for cryopreservation of tissue samples, focusing on a slam freezing method that minimizes deformation. It details the system's design requirements, including maximum cooling rates, sample handling, and cost efficiency, with a total projected cost under $5,000. The document also outlines future work for testing and development to further improve the system's effectiveness and user interaction.

![Mirror Module: Material Selection Cooling Rates of Various Liquid Cryogen Echlin, Patrick. Low-Temp Microscopy and Analysis . New York: Plenum Press, 1992. Thermal Conductivity and Inertia of Various Materials Material Temperature [K] Specific Heat [J/(g∙K)] Thermal Conductivity [ J/(m∙s∙K)] Thermal Inertia [ Jm 2 /√K ] Aluminum 77 3.7 x 10 -1 410 1.9 20 8.4 x 10 -3 - 1.6 4 2.6 x 10 -4 15,000 0.3 Copper 77 2.1 x 10 -1 570 3.2 20 8.0 x 10 -3 10,500 2.6 4 9.1 x 10 -5 11,300 0.3 Gold 77 9.6 x 10 -2 252 2.6 20 1.6 x 10 -2 1,500 2.4 4 1.6 x 10 -4 1,710 2.3 Sapphire 77 6.3 x 10 -2 960 1.6 20 2.0 x 10 -2 15,700 0.6 4 8.0 x 10 -6 410 0.1 Silver 77 1.5 x 10 -1 471 2.9 20 1.3 x 10 -2 5,100 2.7 4 1.3 x 10 -4 14,700 0.4 Cryogen Temperature Mean Cooling Rate ( ° K) (10 3 ° K/s) Ethane 90 13-15 Liquid Helium 4.3 0.1 Liquid Nitrogen 77 0.5 Propane 88 10-12](https://image.slidesharecdn.com/SlamFreezingFINAL-123422192587-phpapp01/85/Slam-Freezing-For-Electron-Microscopy-10-320.jpg)

![Basin: Heat Transfer Analysis Energy Balance: Liters of LN 2 Required = 12.8654L Heat transfer rate per unit area through basin: q”= 181 [W/m 2 ] with EPS @ 1.5” AIR EXT BOX INNER BASIN INSULATION LIQUID NITROGEN](https://image.slidesharecdn.com/SlamFreezingFINAL-123422192587-phpapp01/85/Slam-Freezing-For-Electron-Microscopy-16-320.jpg)