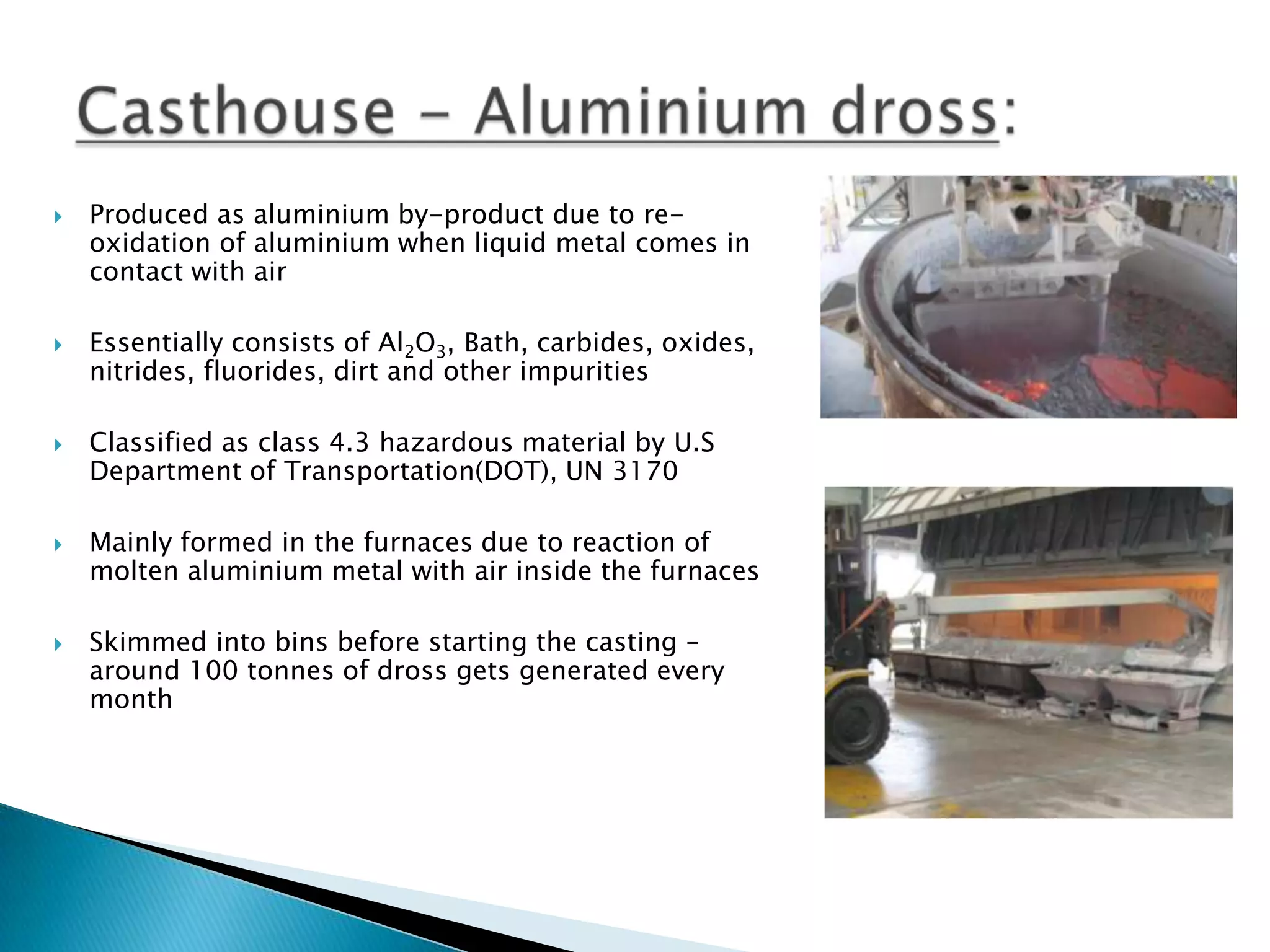

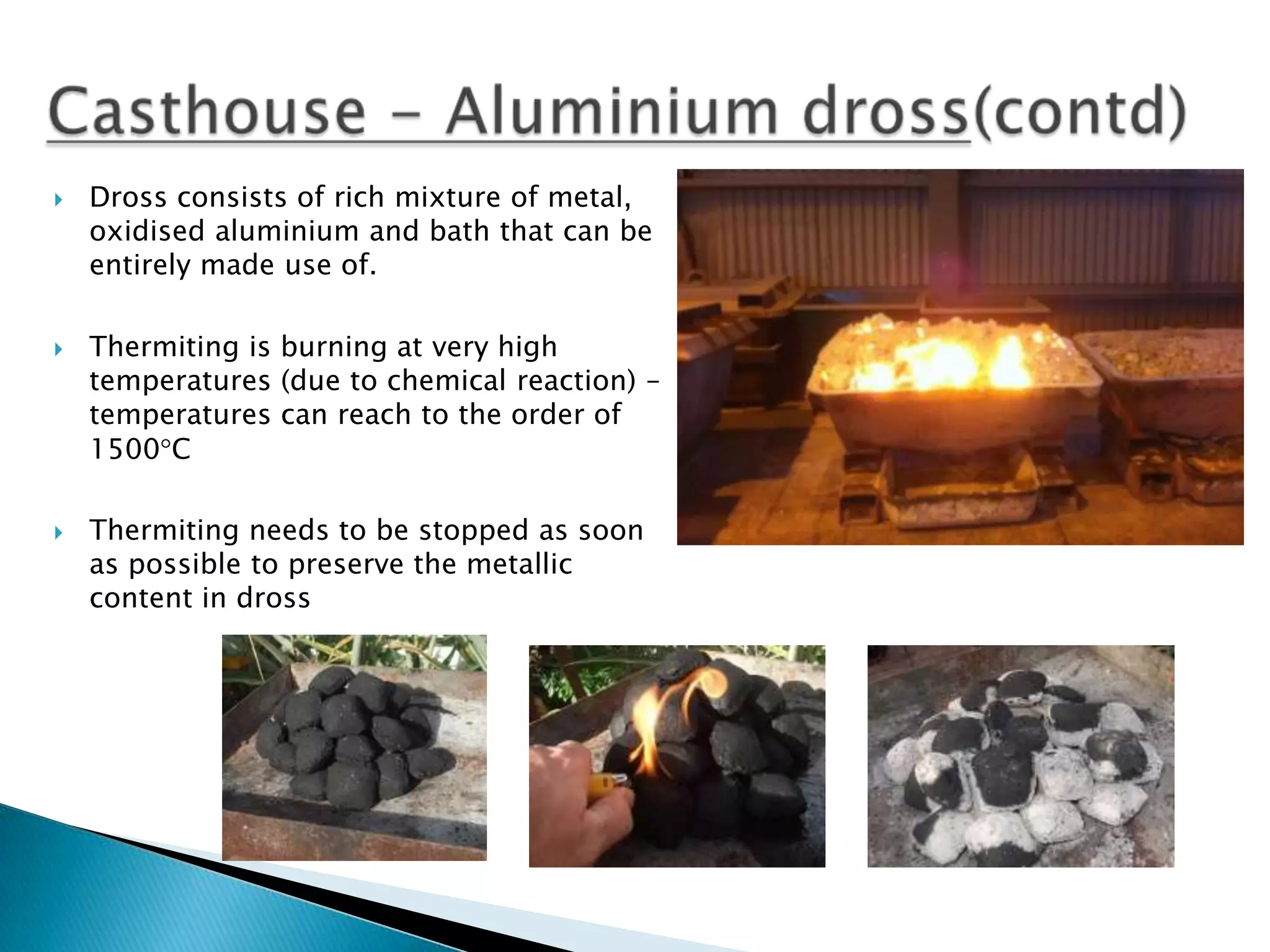

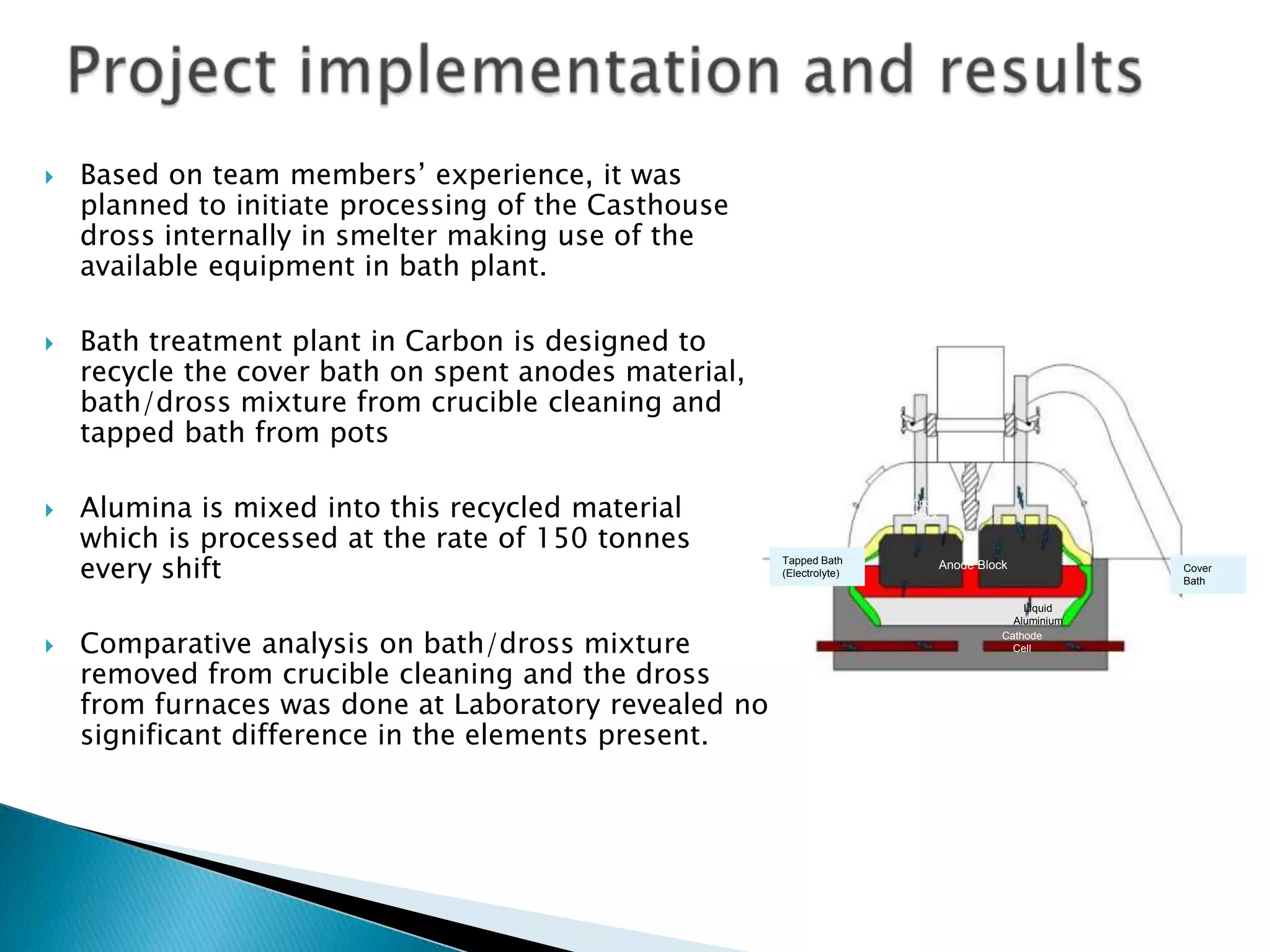

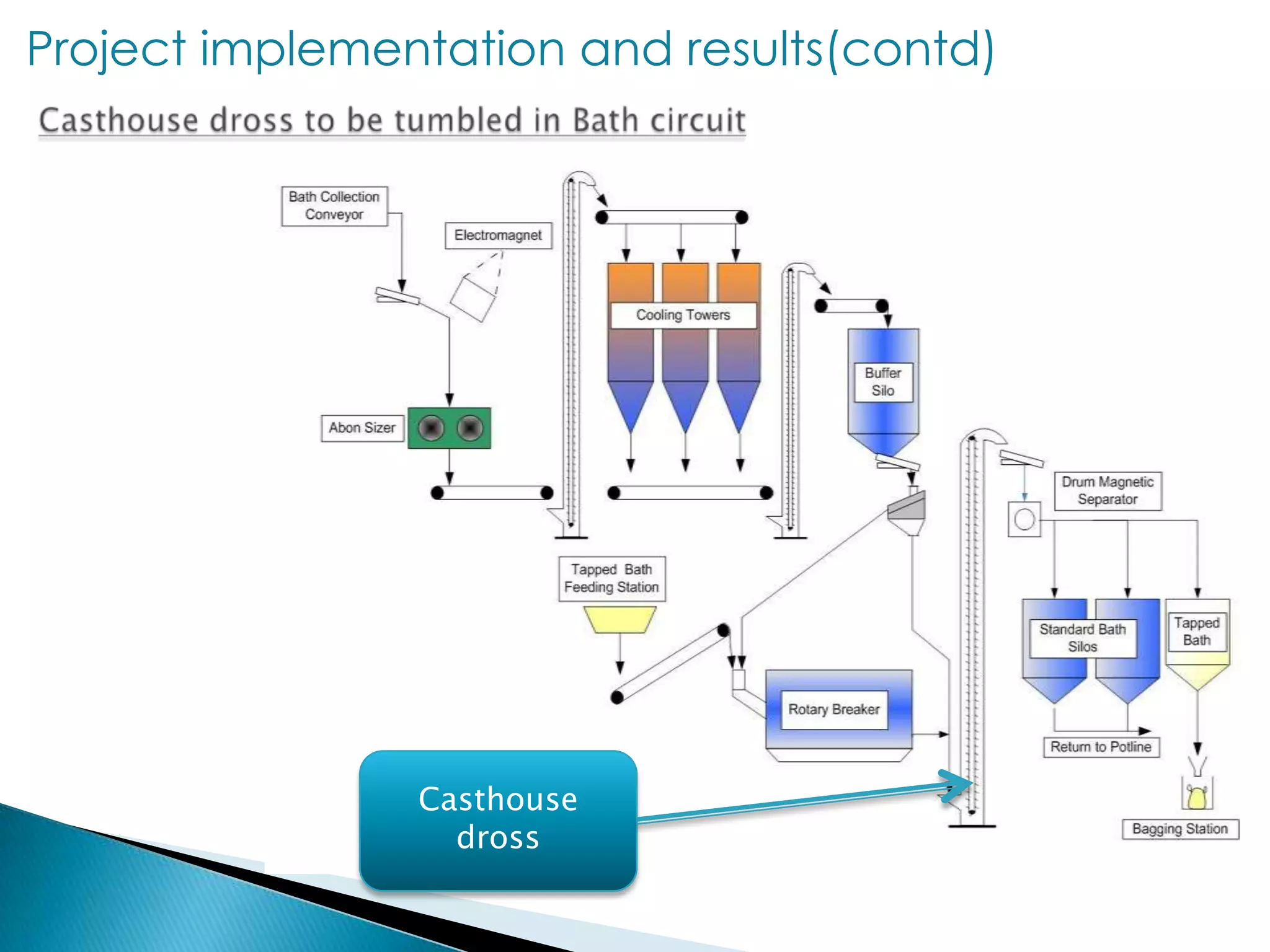

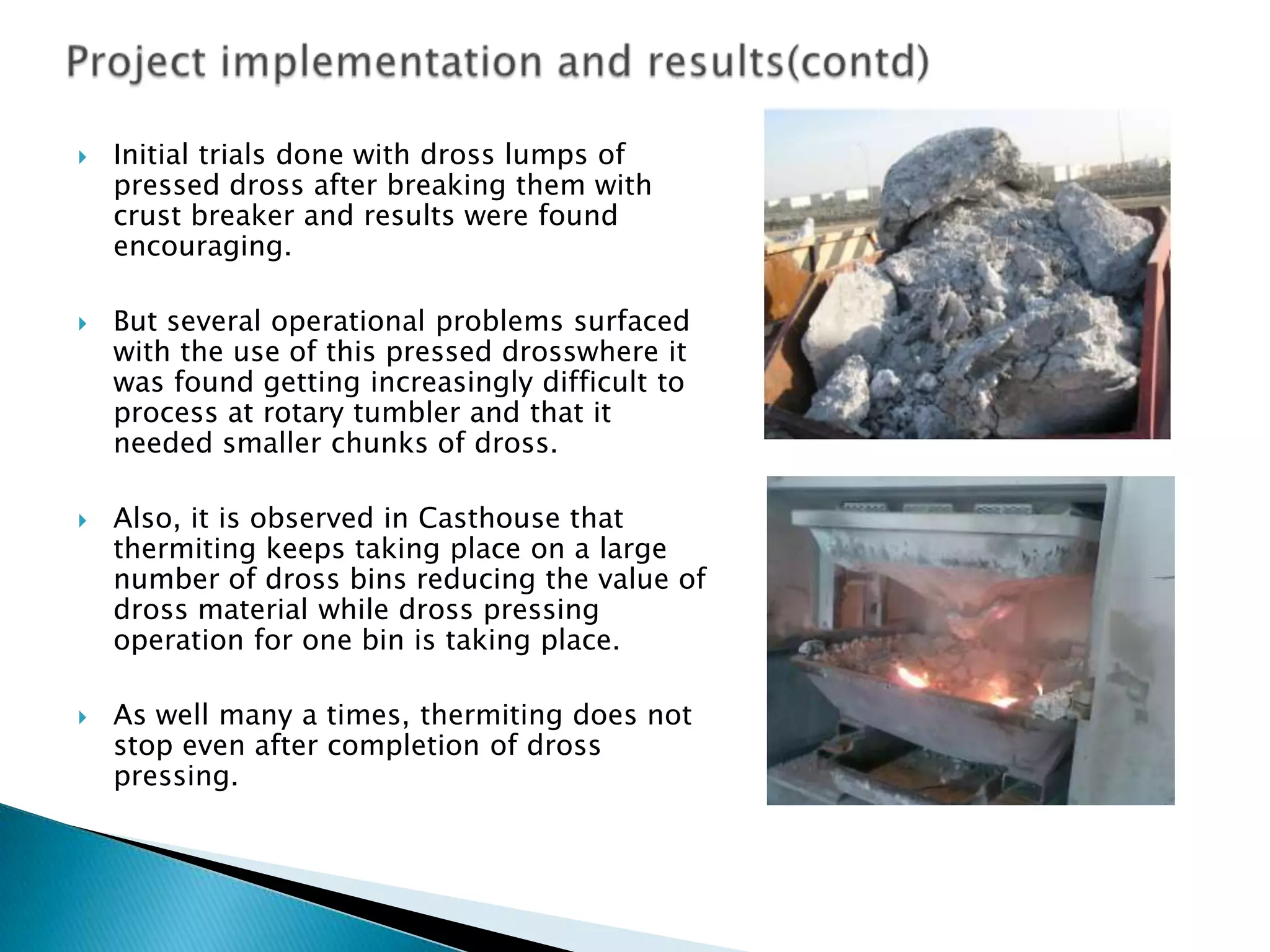

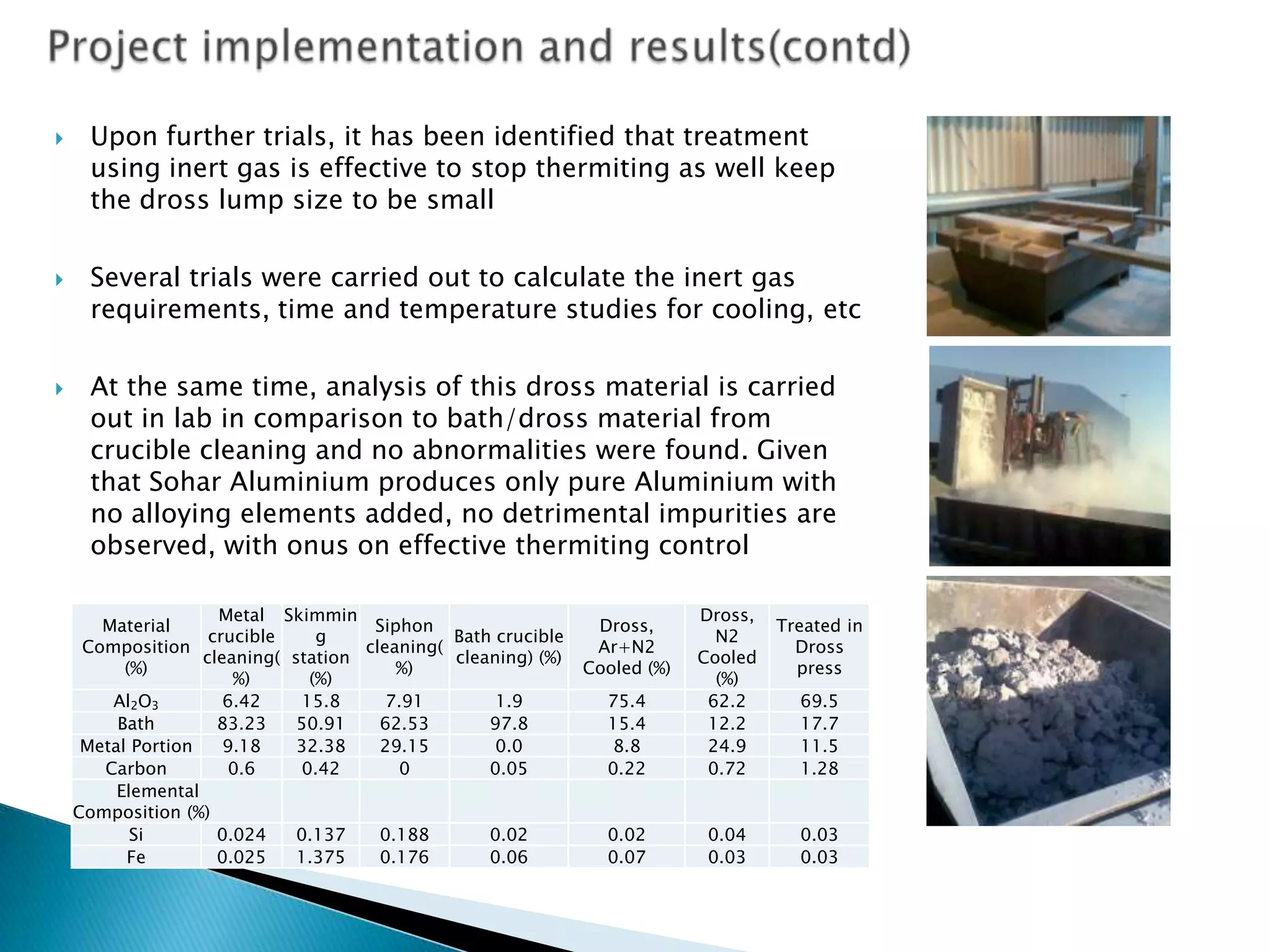

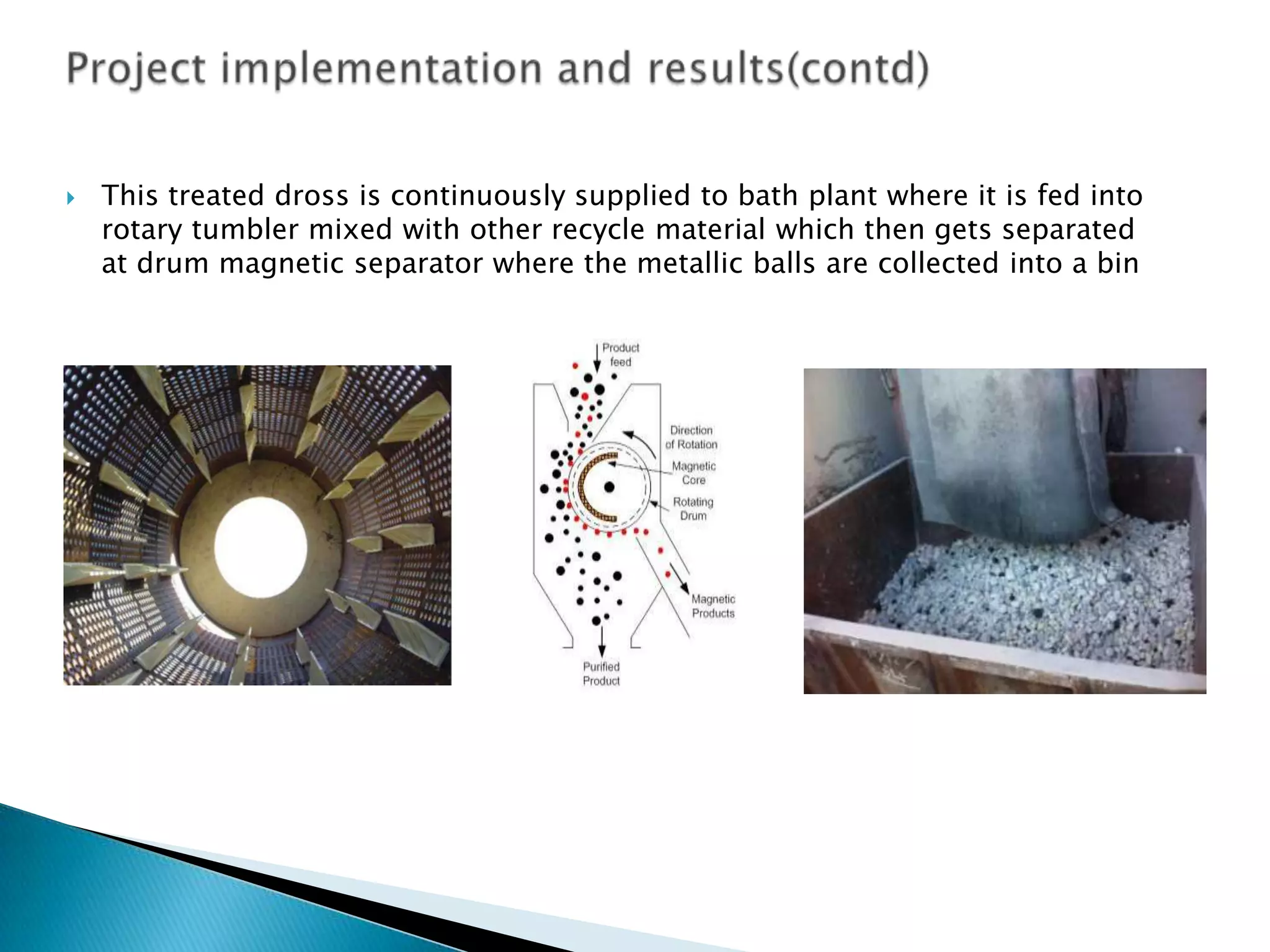

This document summarizes a project at Sohar Aluminium to handle hazardous aluminum dross generated at the casthouse. It discusses how dross is formed, its composition, and initial challenges with accumulation. The project implemented internal dross processing by cooling it with inert gas to stop combustion, then feeding it into the bath plant for separation and metal recovery. These improvements addressed dross issues, reduced waste, and allowed for complete recycling and cost benefits.