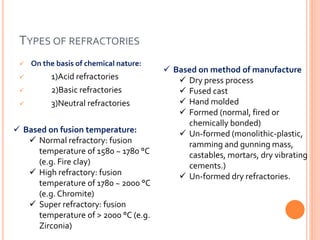

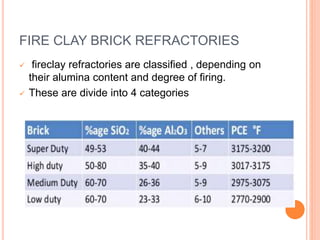

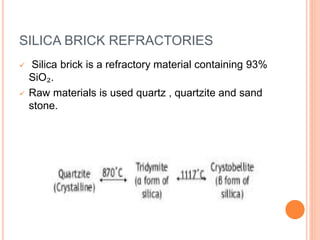

There are three main types of refractories based on their chemical nature: acidic, basic, and neutral. Refractories can also be classified based on their fusion temperature into normal, high, and super refractories. Manufacturing methods include dry press, fused cast, hand molded, and formed/unformed. Formed refractories include plastic, ramming masses, castables, mortars, and dry vibrating cements. Common refractories include fireclay, silica, magnesite, mullite, chrome-magnesite, carbide, and insulating refractories which are used as heat barriers. Each refractory has specific properties and applications depending on their chemical composition and temperature resistance.