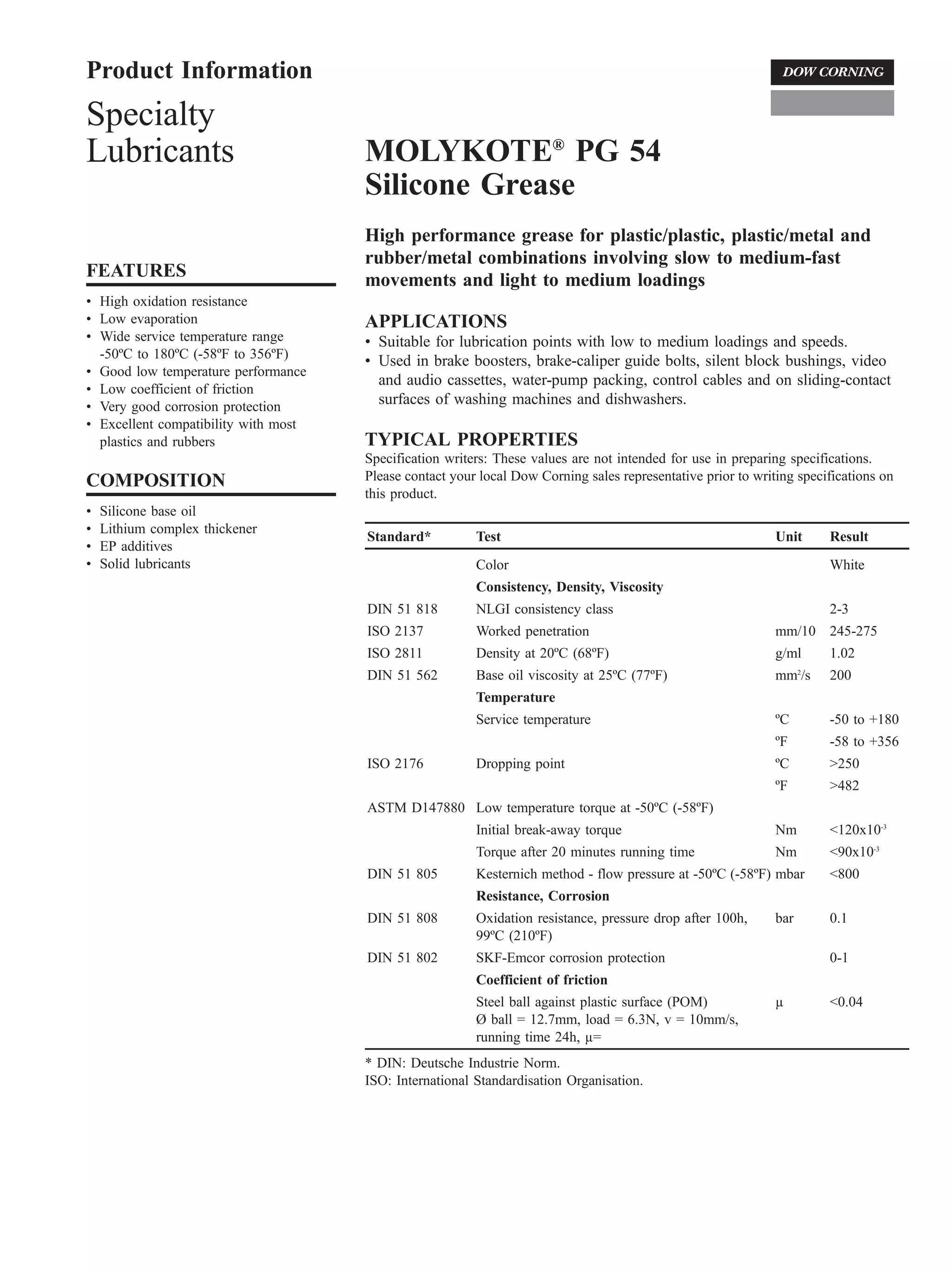

Molykote PG 54 is a high performance silicone grease for plastic/plastic, plastic/metal, and rubber/metal combinations involving slow to medium-fast movements and light to medium loadings. It has high oxidation resistance, a wide service temperature range of -50°C to 180°C, good low temperature performance, and excellent compatibility with most plastics and rubbers. Molykote PG 54 is suitable for lubrication points requiring low to medium loadings and speeds, and is used in applications such as brake boosters, video and audio cassettes, and sliding surfaces of washing machines.