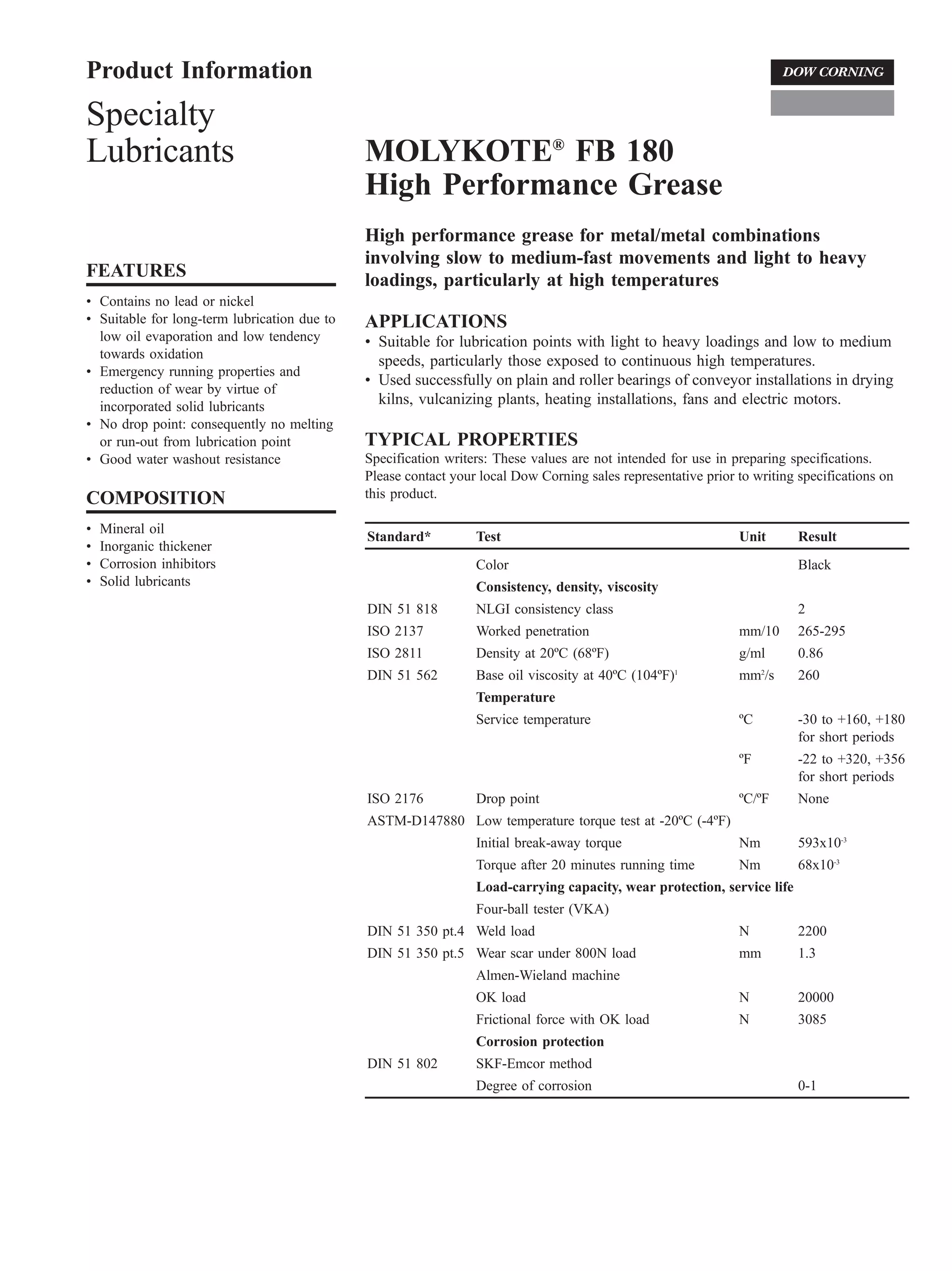

This document provides product information for MOLYKOTE® FB 180 High Performance Grease. It is a high temperature grease suitable for slow to medium-fast metal/metal combinations under light to heavy loads. It contains no lead or nickel and has good oxidation resistance and emergency running properties. Typical properties include a black color, NLGI consistency class of 2, and service temperature range of -30 to +160°C. The grease is packaged in standard container sizes and has a usable life of 60 months when stored properly.