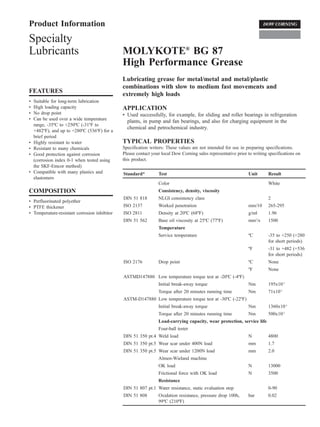

1. Molykote BG 87 is a high performance grease suitable for long-term lubrication under extremely high loads and over a wide temperature range of -35°C to +250°C.

2. It has a high loading capacity and is resistant to water, corrosion, and many chemicals. It is also compatible with plastics and elastomers.

3. The grease is used for sliding and roller bearings in refrigeration equipment and pumps, as well as charging equipment in chemical plants.