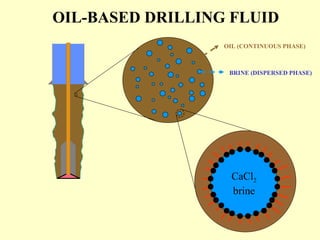

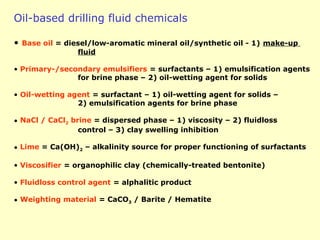

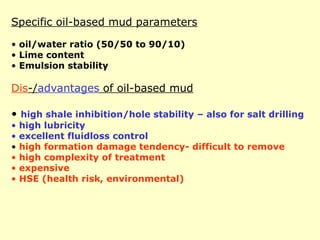

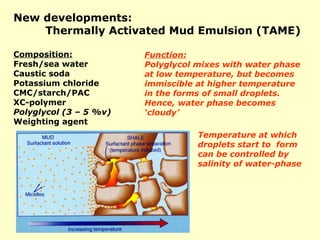

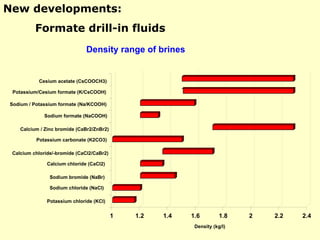

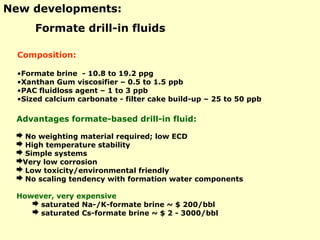

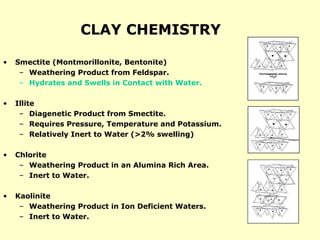

The document discusses drilling fluids as engineered tools that enhance drilling performance, minimize costs, and reduce environmental impacts. It outlines various components and functions of water-based and oil-based drilling fluids, emphasizing their chemical makeup, properties, and significance in drilling operations. New developments in drilling fluid technology, including thermally activated mud emulsions and formate-based drill-in fluids, are also mentioned, highlighting their advantages and specific applications.

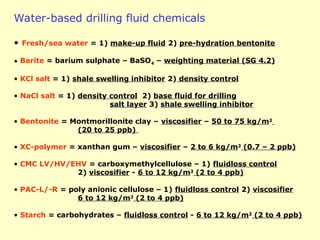

![Water-based drilling fluid chemicals

• Lime = Ca(OH)2 – pH buffer in case of H2S

• Ironite Sponge = Fe3O4 – H2S scavenger

• Zinc carbonate = ZnCO3 – H2S scavenger

• [Sulphonated] asphalt = plugging agent for shale formations

• Walnut shells, mica flakes, marble chips = lost circulation material

•Calcium carbonate = CaCO3 – 1) acid-soluble weighting material –

2) Lost circulation material](https://image.slidesharecdn.com/4-240903095630-8df4d35e/85/drilling-fluids-at-drilling-rigs-and-cement-5-320.jpg)

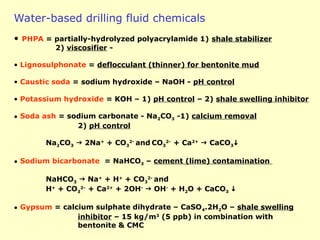

![H2O H+

+ OH-

pH = -log [H+

] where H+

is the hydrogen concentration in mol/l

pOH = -log [OH-

] where OH-

is the hydroxide concentration in mol/l

pH + pOH = 14

pH range

Example:

pH = 10 pOH = 4 [OH-

] concentration = 10-4

mol/l (1 mol = 17 gram)

Caustic soda added to water: NaOH Na+

+ OH-

Lime added to water: Ca(OH)2 Ca2+

+ 2OH-

(largely insoluble)

<7 = Acidic

7

>7 = Alkaline](https://image.slidesharecdn.com/4-240903095630-8df4d35e/85/drilling-fluids-at-drilling-rigs-and-cement-6-320.jpg)