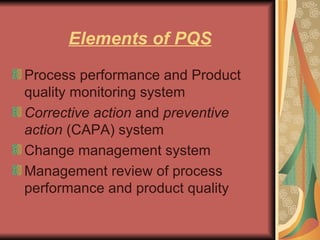

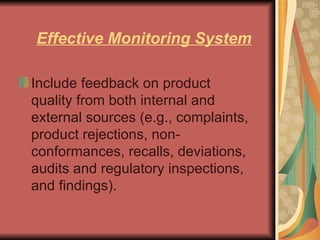

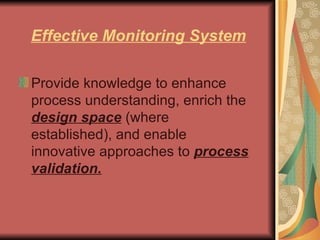

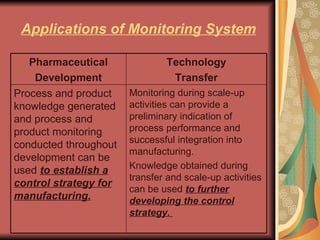

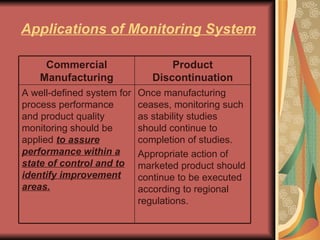

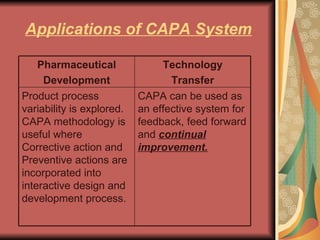

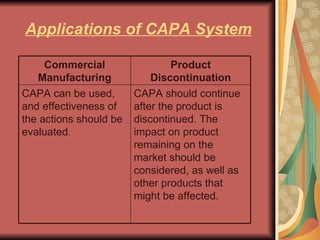

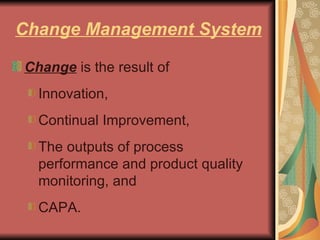

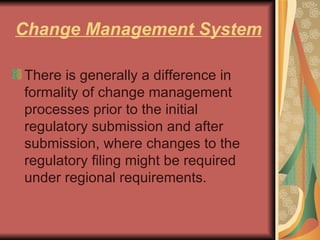

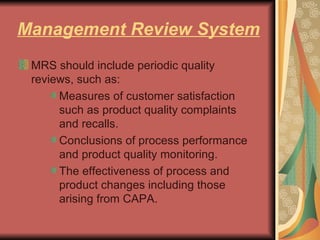

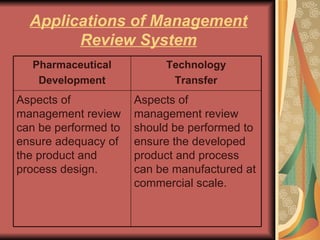

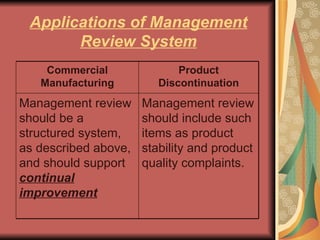

The document outlines the elements of a Pharmaceutical Quality System (PQS) as per ICH Q10, emphasizing the importance of effective management and application of these elements throughout the product lifecycle. Key components include process performance monitoring, corrective action and preventive action (CAPA), and change management systems, which together aim to enhance product quality and ensure compliance with regulations. Additionally, it highlights the need for structured management reviews to assure ongoing quality oversight and facilitate continual improvement.