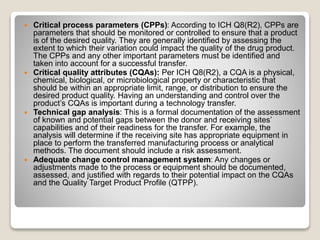

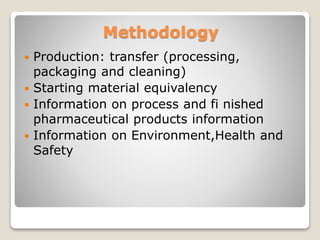

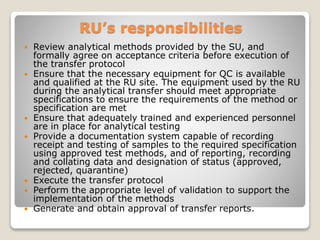

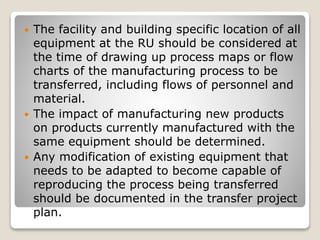

The document discusses technology transfer in the pharmaceutical industry. It defines technology transfer as sharing development and manufacturing knowledge across teams and sites. A successful transfer requires transferring documentation like manufacturing processes, analytical methods, critical process parameters, and equipment from a donor site to a receiving site. The receiving site must ensure it has the proper facilities, equipment, personnel and processes to replicate what is being transferred. A technology transfer project involves preparing transfer plans and documents, evaluating any gaps, and conducting activities like process validation to verify the receiving site can successfully produce the product.