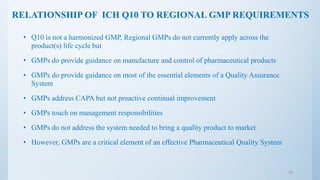

This document presents an overview of the Pharmaceutical Quality Systems (ICH Q10) guideline. ICH Q10 establishes a quality management system model for the pharmaceutical industry and was intended to help companies comply with Good Manufacturing Practices. The objectives of ICH Q10 are to achieve product realization, establish control, and facilitate continual improvement. ICH Q10 also discusses management responsibility, risk management, challenges of implementing the new system, and the relationship between ICH Q10 and other quality standards like GMP.