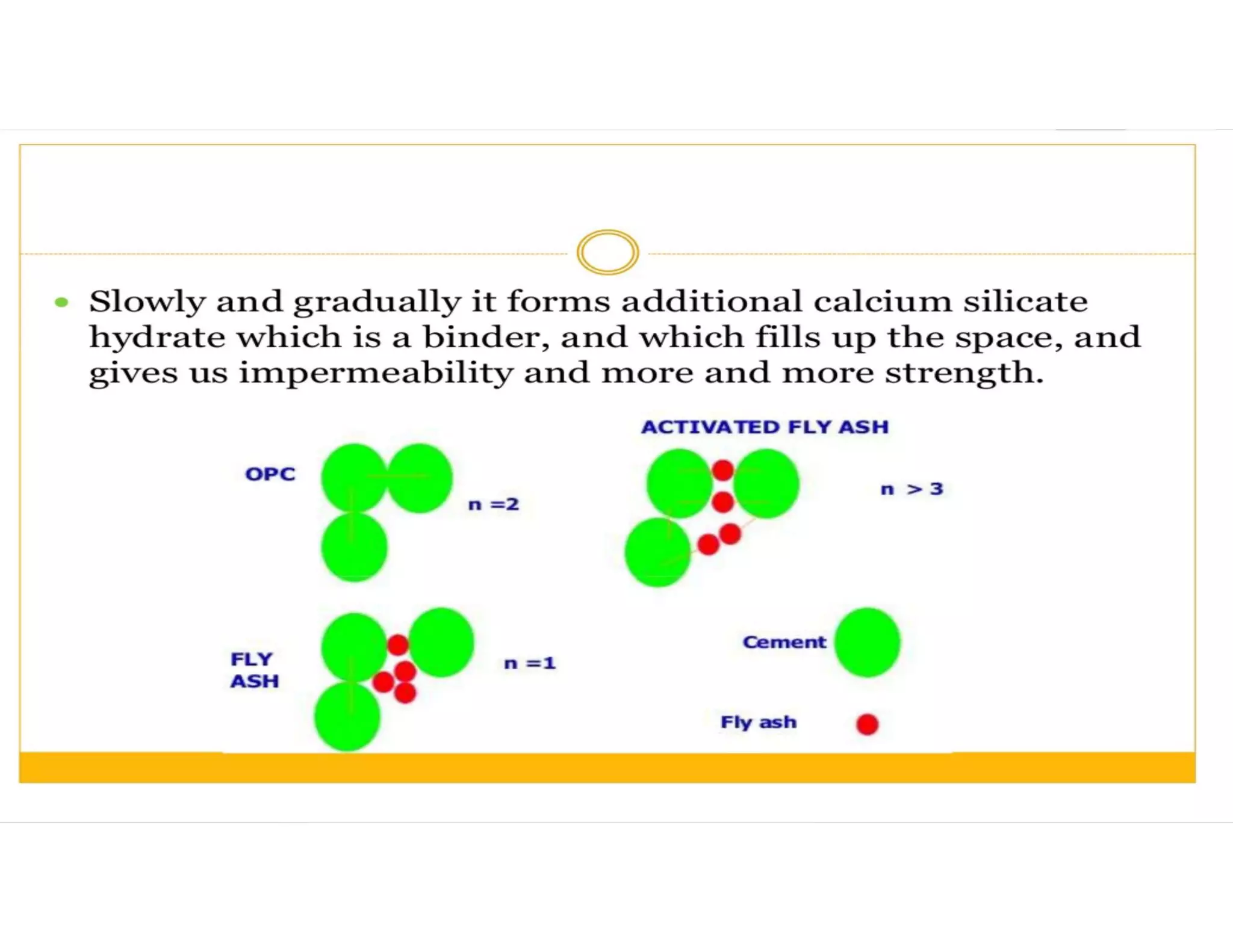

This document discusses pozzolana and fly ash in concrete technology. It defines pozzolana as a finely powdered material that can be added to lime or cement mortar to increase durability by chemically reacting with calcium hydroxide. The document lists various natural and manufactured sources of pozzolanic materials including volcanic ash, calcined clay, mineral slag, and ashes of organic origin. It describes how the properties of pozzolanic materials like particle size and chemical composition affect their reactivity and the strength and setting of composites. The document also discusses how pozzolanic reactions enhance concrete properties like stiffness over time and that pozzolanic materials can improve sustainability by enabling the use of industrial and