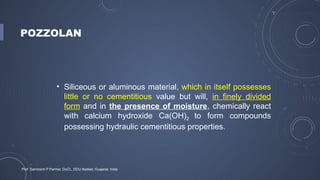

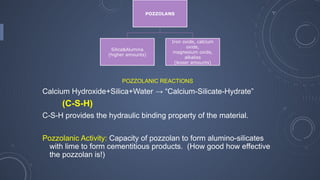

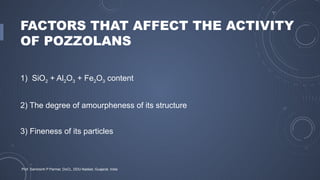

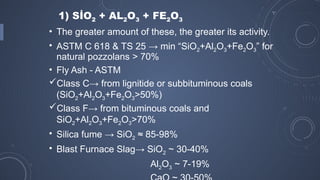

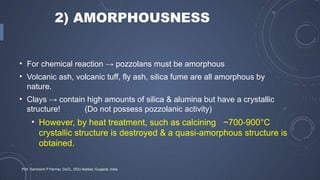

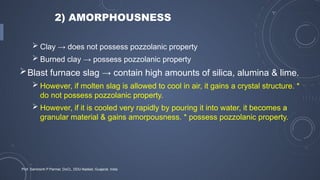

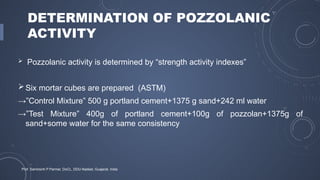

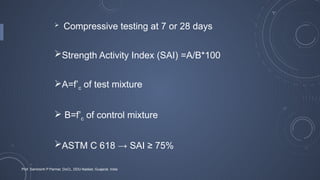

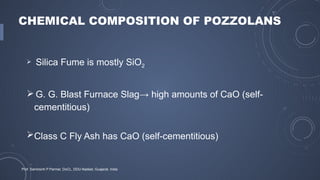

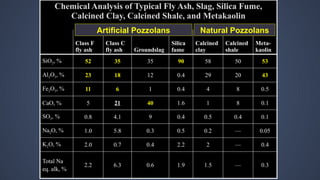

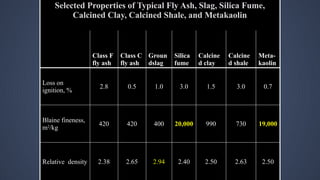

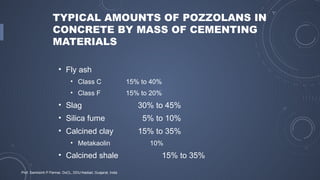

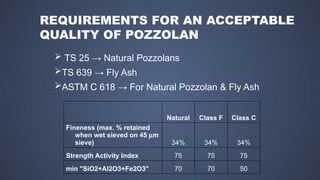

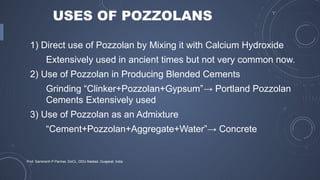

The document discusses pozzolans, materials that enhance the properties of concrete through hydraulic or pozzolanic activity, with a historical background on their use dating back to ancient Romans. It outlines the types of pozzolans (natural and artificial), their chemical composition, factors affecting their activity, and methods to determine their effectiveness, such as the strength activity index. Additionally, it addresses the typical amounts used in concrete and requirements for acceptable quality as per various standards.