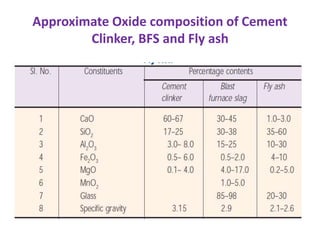

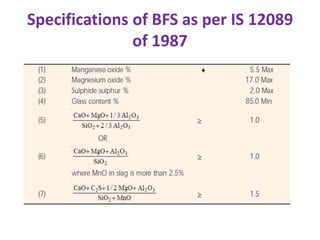

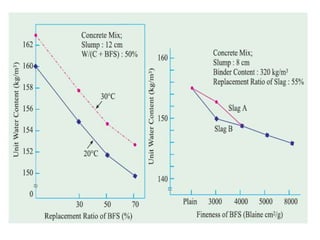

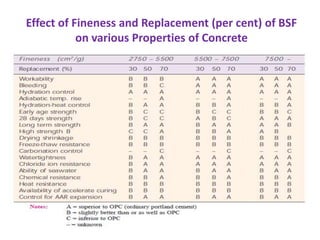

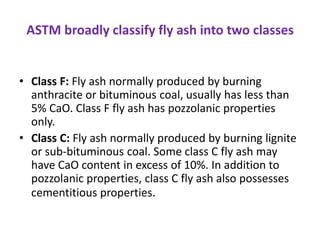

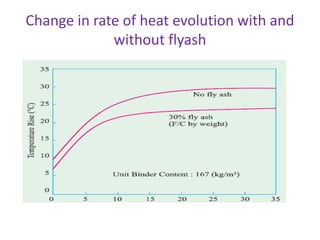

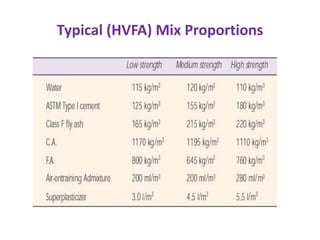

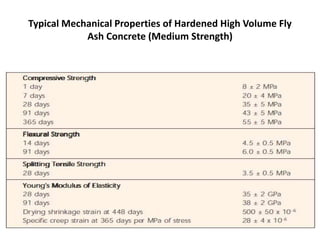

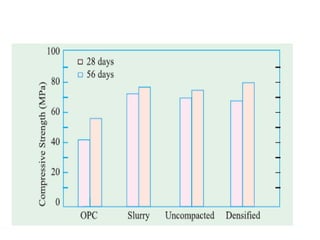

This document provides information on various types of admixtures used in concrete. It discusses mineral admixtures including slag, pozzolanas and fillers. It describes different chemical admixtures such as accelerators, retarders, air entraining agents, water reducers, plasticizers, and super plasticizers. Specific admixtures like fly ash, GGBS, and silica fume are explained in detail along with their effects on fresh and hardened concrete. High volume fly ash concrete and its properties are also summarized.