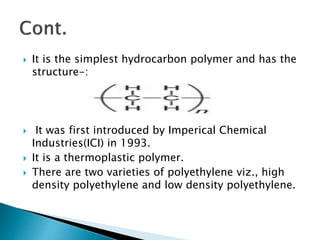

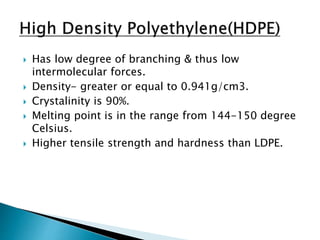

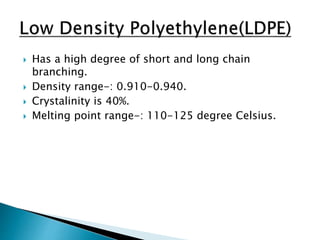

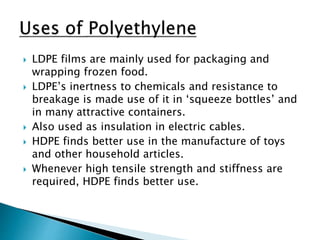

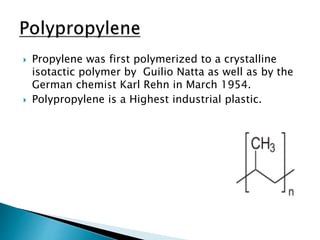

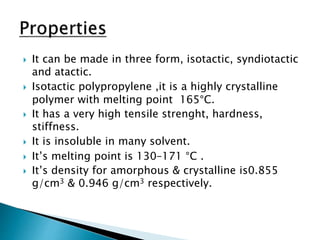

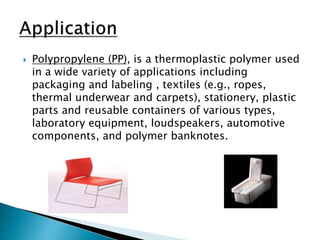

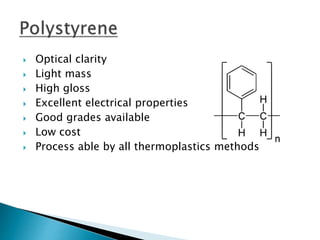

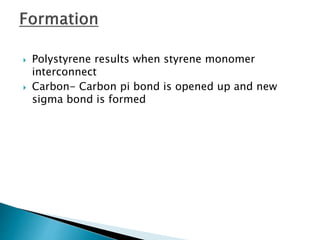

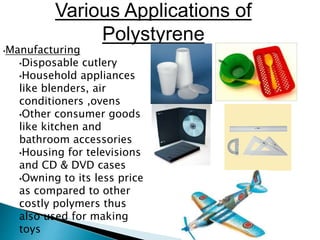

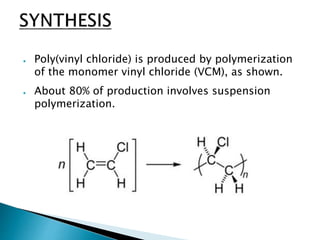

The document discusses polymers and their uses in everyday life. It provides information on different types of polymers like polyethylene, polypropylene, polystyrene, poly(methyl methacrylate), poly(vinyl chloride) and discusses their structures, properties and applications. The document also discusses the synthesis and uses of important polymers.

![ PMMA is a strong and lightweight material. It has a

density of 1.17–1.20 g/cm3,, which is less than

half that of glass.]

It also has good impact strength, higher than both

glass and polystyrene;

however, PMMA's impact strength is still

significantly lower than polycarbonate and some

engineered polymers.

PMMA ignites at 460 °C (860 °F) and burns, forming

carbon dioxide, water, carbon monoxide and low-

molecular-weight compounds, including

formaldehyde.](https://image.slidesharecdn.com/polymersineverydaylife-170704085832/85/Polymers-in-everyday-life-28-320.jpg)

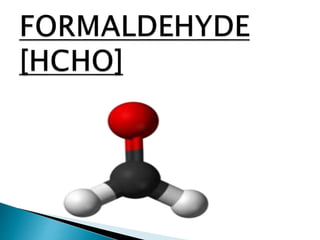

![ Formaldehyde is also a precursor to polyfunctional

alcohols such as pentaerythritol [ C5H12O4 ], which

is used to make paints and explosives.

The textile industry uses formaldehyde-based

resins as finishers to make fabrics crease-resistant.

When treated with phenol, urea, or melamine,

formaldehyde produces, respectively, hard

thermoset phenol formaldehyde resin, urea

formaldehyde resin, and melamine resin. These

polymers are common permanent adhesives used

in plywood and carpeting.](https://image.slidesharecdn.com/polymersineverydaylife-170704085832/85/Polymers-in-everyday-life-46-320.jpg)