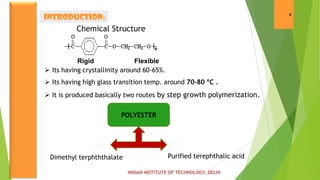

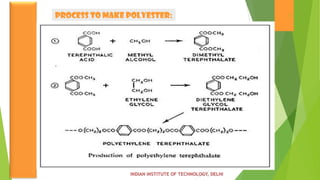

1. The document discusses the recycling of polyester, specifically polyethylene terephthalate (PET). PET is commonly used in textiles and plastic bottles.

2. Recycled PET (rPET) is considered more environmentally friendly than virgin PET as it uses less energy and emits fewer carbon emissions. rPET can be used to make new textiles, carpets, and sleeping bags.

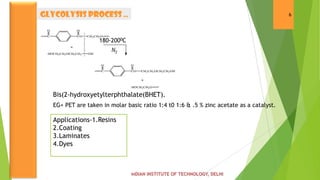

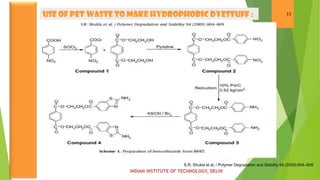

3. The document then outlines processes for depolymerizing and recycling PET waste through glycolysis. The recycled PET can be used to produce polyester polyols, coatings, textile softeners, and hydrophobic dyes. It can also be used as reinforcement in concrete and to strengthen recycled paper.