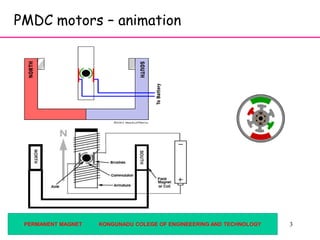

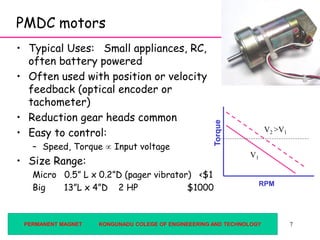

The document discusses permanent magnet DC (PMDC) motors. It describes the basic components and working principle of PMDC motors, including how torque is produced via the interaction between current in the armature coils and the magnetic field from permanent magnets. The document also discusses motor performance curves, efficiency calculations, motor sizing based on load requirements, and applications of PMDC motors.