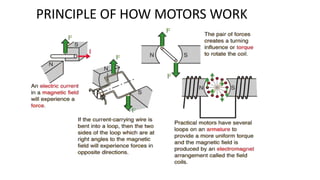

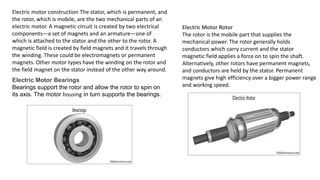

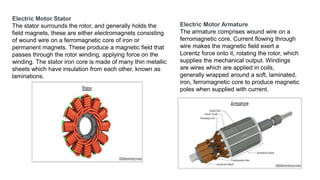

An electric motor converts electrical energy into mechanical energy. It consists of a stator and a rotor, with magnetic fields interacting to produce torque and rotate a shaft. Common types include AC induction motors, DC motors, servo motors, and stepper motors. Electric motors are widely used in industry, appliances, vehicles, and other applications due to their efficiency, reliability and controllability. Proper maintenance and care is required to prevent issues with electric motors.