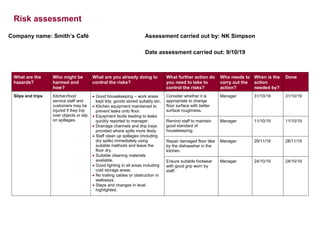

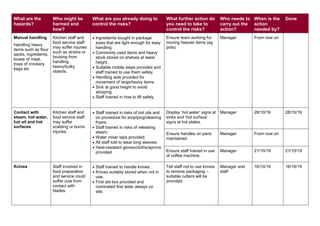

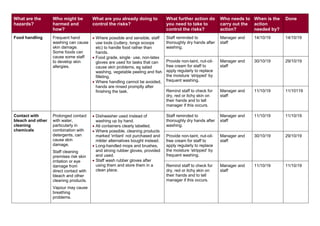

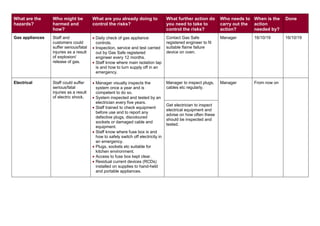

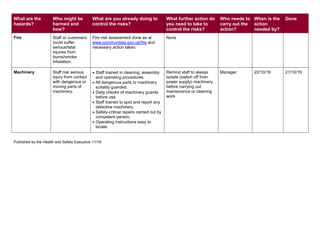

This document outlines a risk assessment for food preparation and service in a café setting, detailing potential hazards, risks to staff and customers, and existing control measures. The café manager conducted the assessment based on guidance from health and safety authorities and involved staff in the process, ensuring that specific actions were assigned to manage identified risks. The assessment emphasizes the importance of customizing risk management strategies to the unique needs of the business.