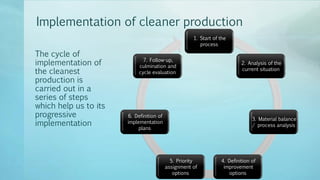

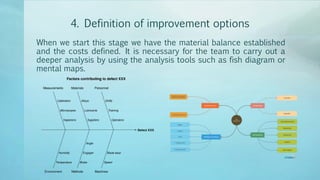

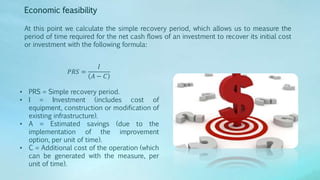

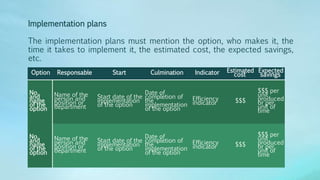

Cleaner production is a strategy to reduce risks to the population and environment by minimizing waste and emissions from processes, products, and services. It identifies deficiencies in production processes and proposes corrective measures. The implementation of cleaner production follows a series of steps: 1) starting the process and analyzing the current situation, 2) material/process analysis, 3) defining improvement options, 4) prioritizing options, 5) implementation planning, and 6) follow-up and evaluation. Benefits include reduced costs, waste, and pollution while improving company image and working conditions.