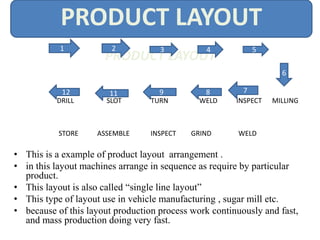

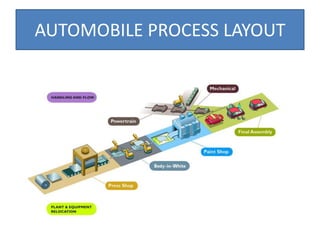

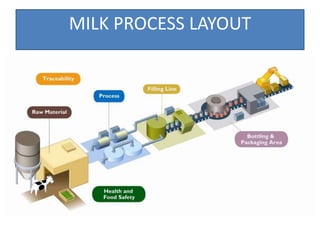

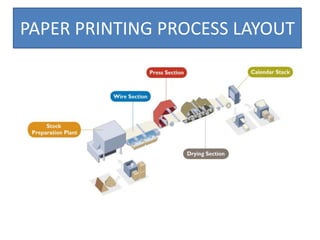

The document outlines a self-employment and entrepreneurship development plan focused on plant layout within manufacturing, detailing its importance for effective production processes. It defines plant layout as the physical arrangement of facilities and discusses different types including process, product, mixed, and static layouts. The importance of plant layout is emphasized through objectives aimed at minimizing material handling, noise, and accidents while optimizing space utilization.