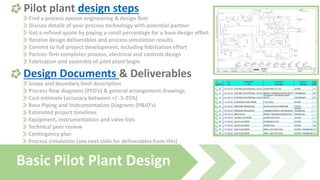

The document outlines the steps and considerations necessary for successful process scale-up and pilot plant design, focusing on reaction kinetics, material properties, and the importance of efficient agitation and thermodynamics. It emphasizes the non-linear nature of scaling systems and details the essential design documents required for a pilot plant project. Additionally, it covers the modeling and simulation processes that enhance project accuracy and planning, as well as installation and commissioning steps.