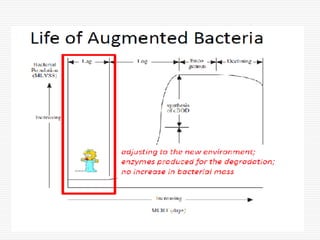

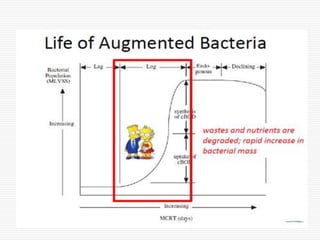

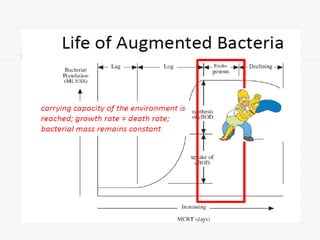

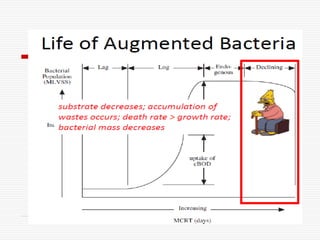

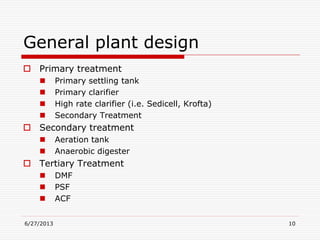

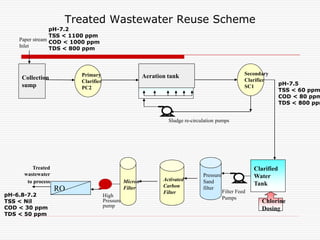

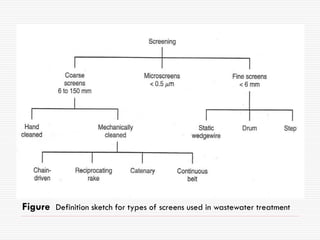

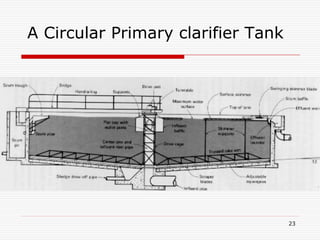

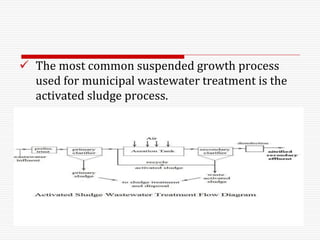

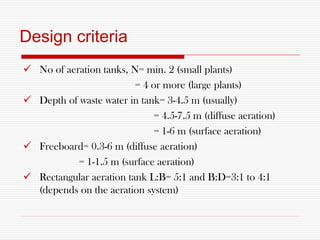

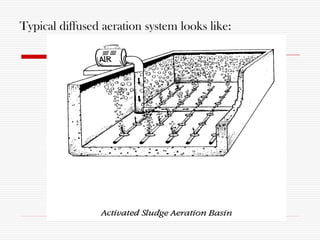

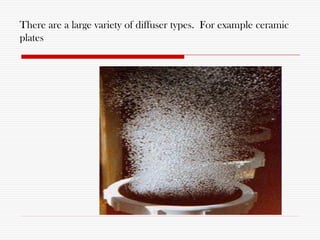

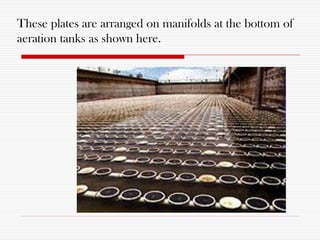

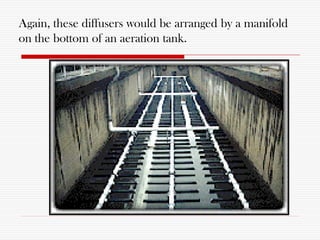

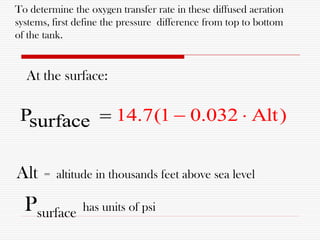

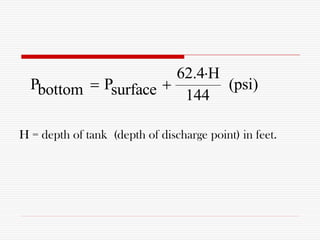

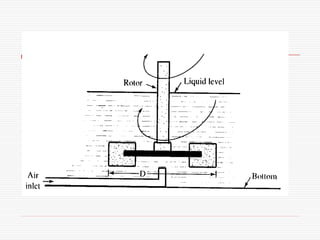

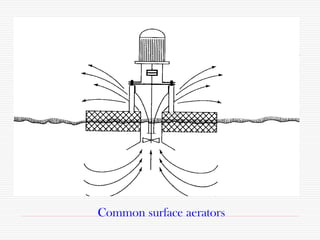

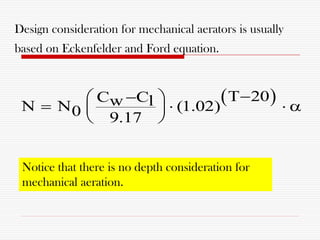

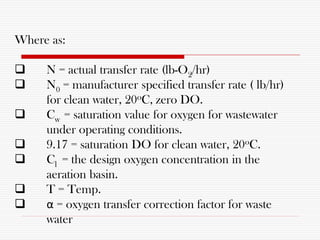

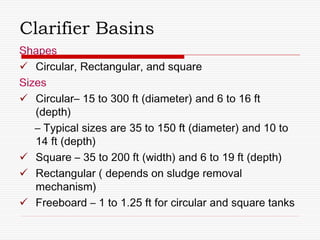

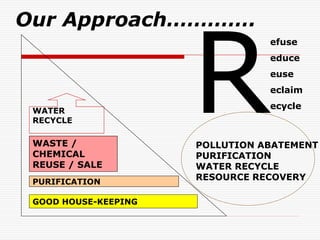

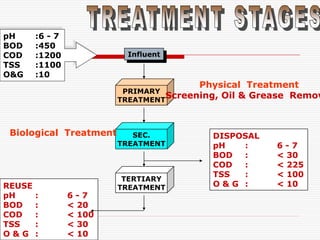

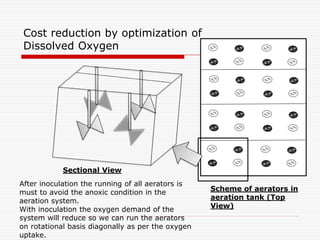

This document provides an overview of a turnkey solution for water and wastewater treatment. It discusses various treatment processes including bioaugmentation, screens, primary clarification, biological processes, and sedimentation tanks. It then focuses on the activated sludge process for secondary treatment, describing the basic process, design considerations like organic loading and aeration requirements, and different aeration methods like diffused, spray, turbine, and surface aeration.