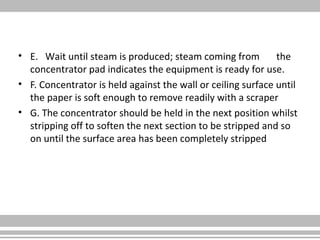

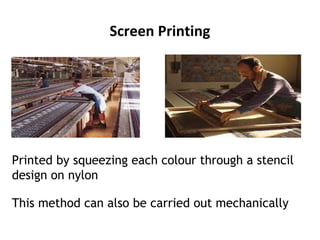

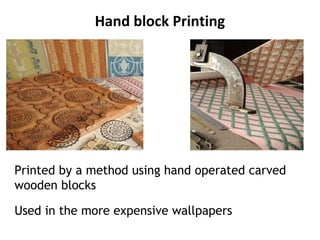

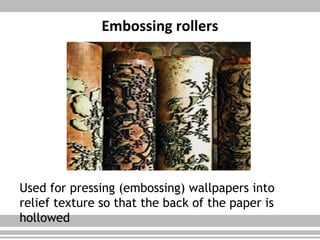

This document provides information on preparing surfaces, lining paper, wallboards, previously painted surfaces, filling cracks and holes, mould growth, new plaster, stripping wallpaper, tools and equipment, pastes and adhesives, paste consistency, how wallpaper is manufactured including screen printing, hand block printing, machine printing and embossing, types of wallpaper including grounds, machine prints, hand prints, embossed papers, wet embossed paper, washable papers, coated washable papers, wood grain, metallic folis and expanded polystyrene.