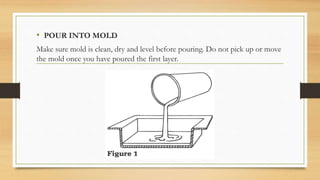

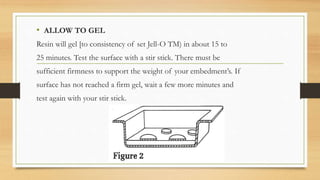

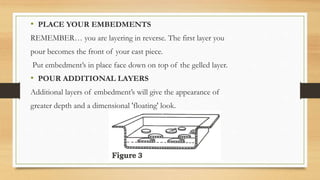

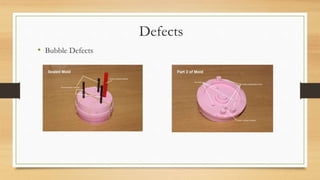

Resin casting is a method of plastic casting where a mold is filled with liquid synthetic resin that then hardens. The process involves measuring the resin and catalyst amounts needed, thoroughly mixing them, pouring the resin into the mold in layers, allowing each layer to gel before adding embedments or additional layers, and finishing the back of the casting. Defects like air bubbles can be prevented by pouring some resin into the mold before adding embedments and gently pressing them to release trapped bubbles.