Partial Use of stone dust in concrete as an alternative of sand

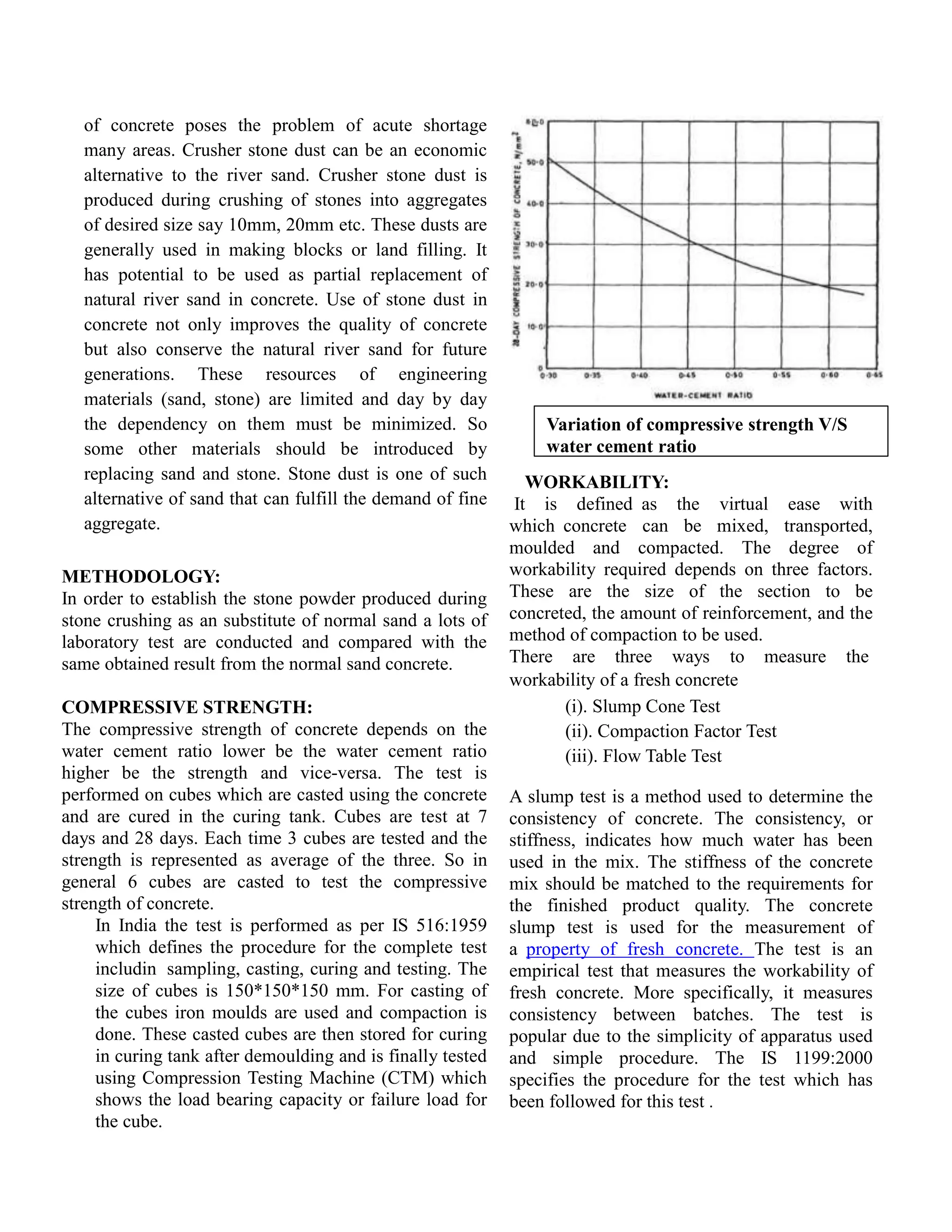

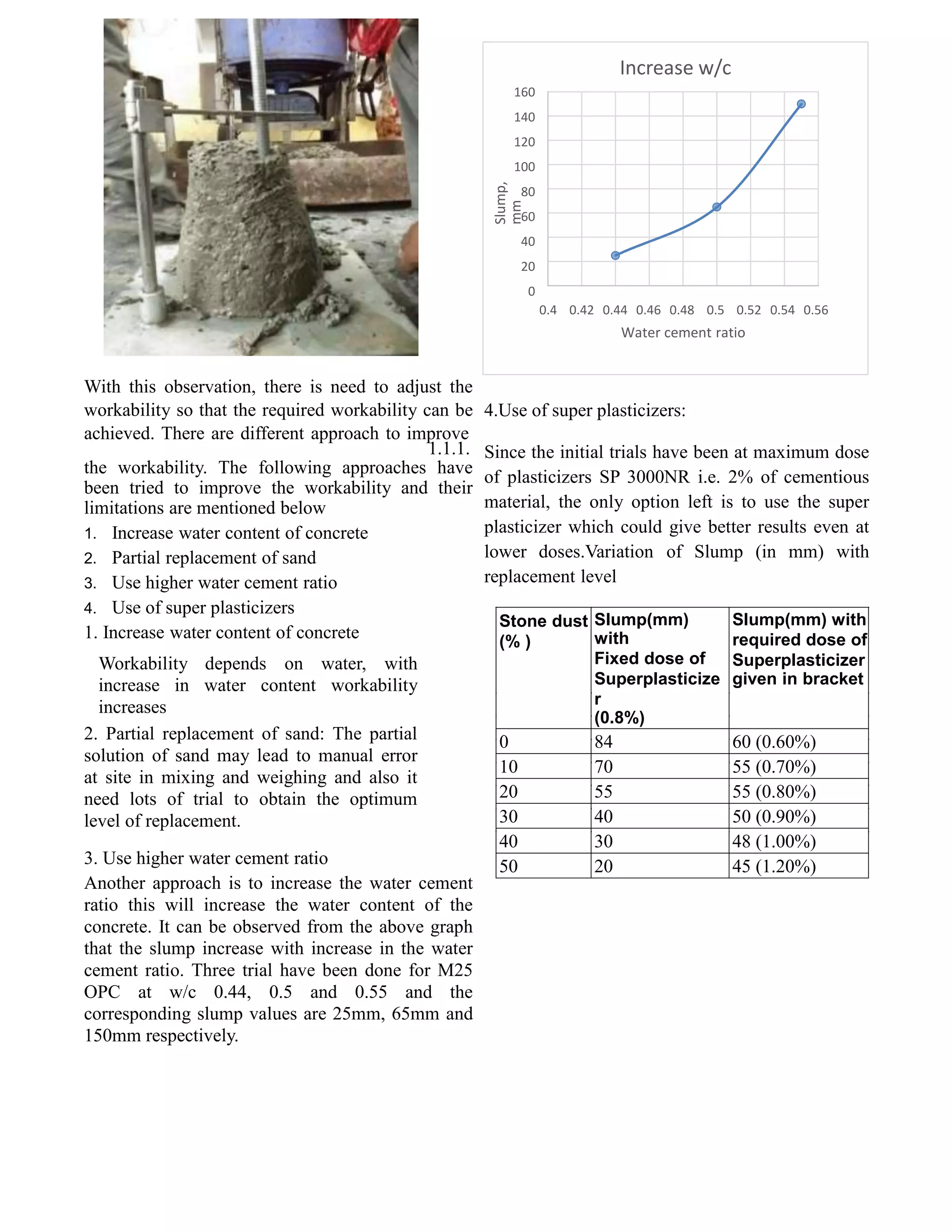

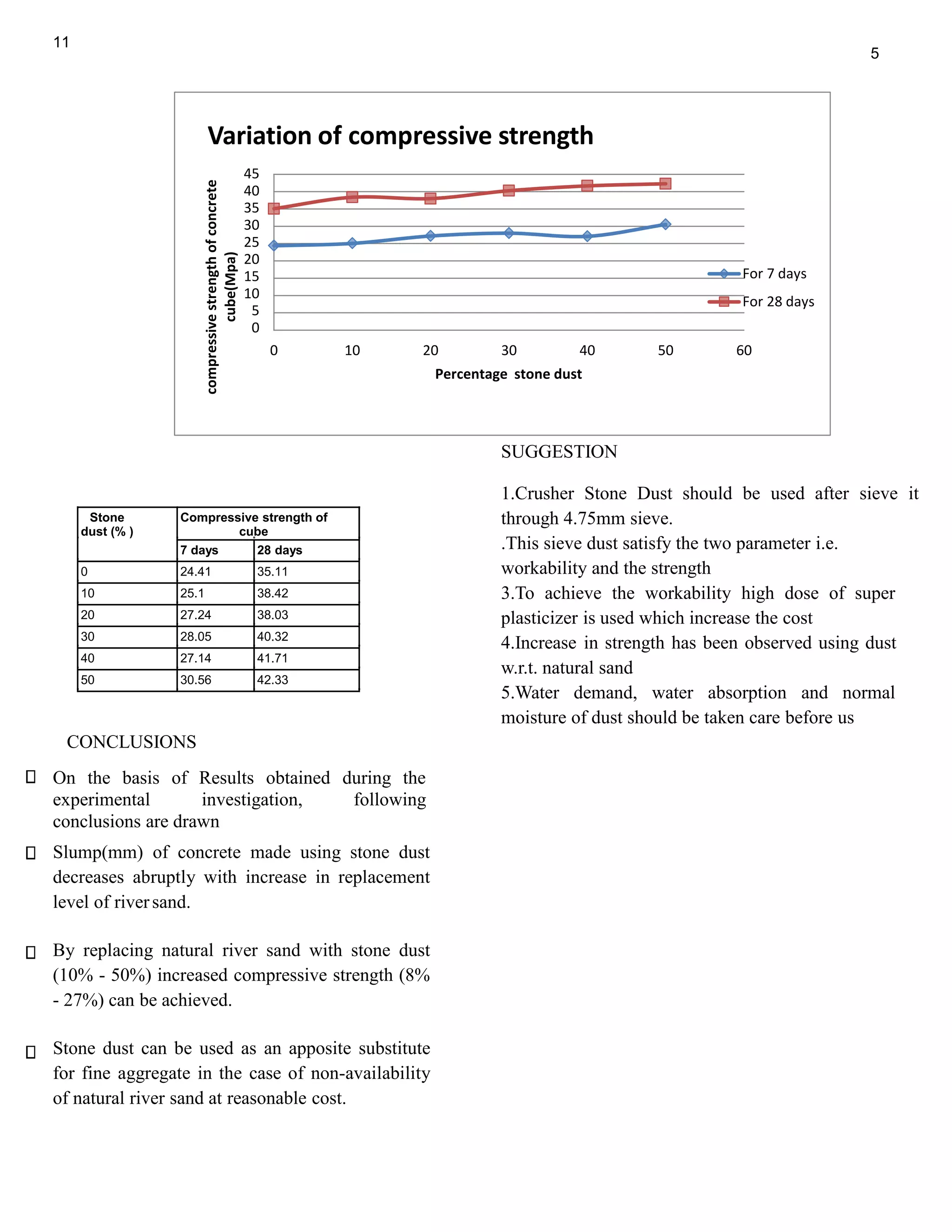

Stone dust can serve as a partial substitute for sand in concrete. Using stone dust from 10-50% as a replacement for sand can increase the compressive strength of concrete cubes by 8-27% at 7 and 28 days. However, workability decreases with higher replacement levels, requiring a higher dosage of superplasticizer. This increases the cost of the concrete by 5-8%. Stone dust meets Indian standards for use as a fine aggregate in concrete and can help conserve natural resources while providing an economic use of waste stone dust from crushing zones. Further testing is needed to determine the optimal replacement level and quality control measures for site use.