The document discusses various topics related to concrete including:

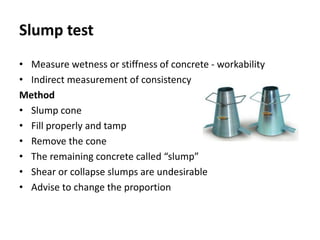

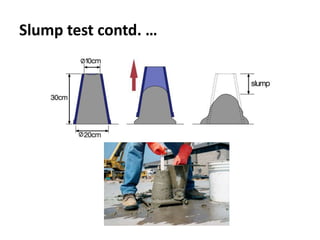

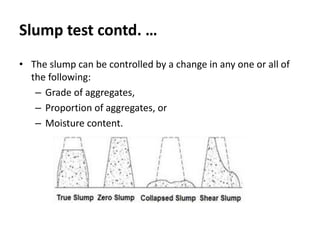

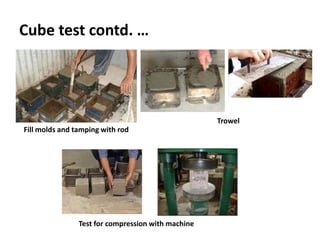

1. Slump and cube tests to measure workability and compressive strength of concrete.

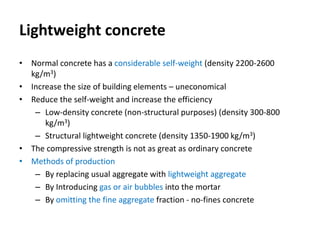

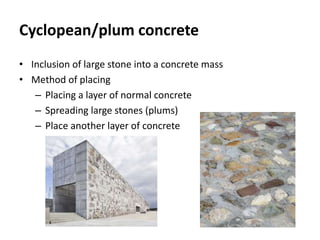

2. Classification of concrete by strength and composition including lightweight and cellular concrete.

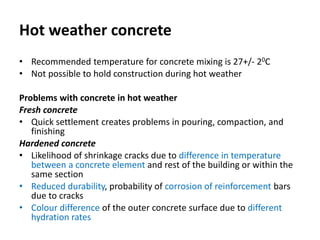

3. Factors that affect concrete such as hot weather, self-compacting, and pumped concrete.

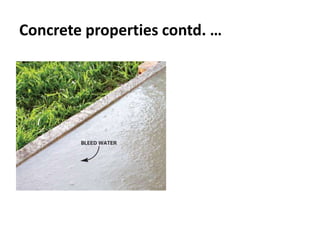

4. Properties of fresh and hardened concrete including workability, segregation, and bleeding.

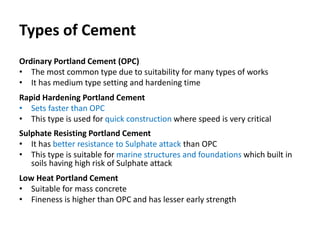

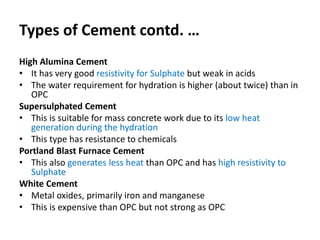

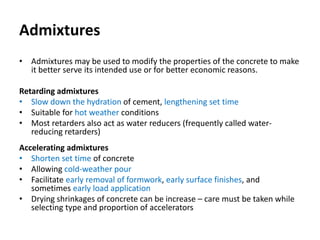

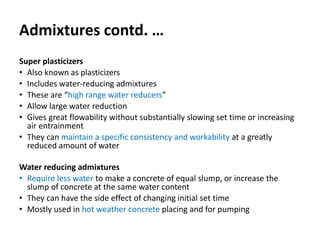

5. Types of cement and admixtures used to modify concrete properties.

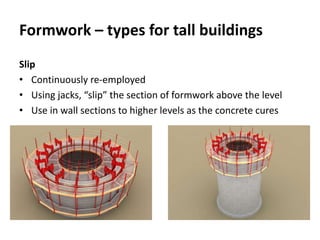

6. Formwork used to mold wet concrete including materials, bracing, and types for tall buildings.