The document outlines the key elements of the OSHA Process Safety Management (PSM) Standard including:

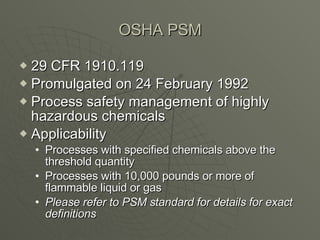

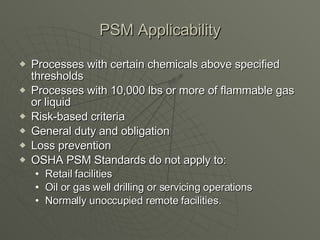

1) The PSM standard applies to processes involving certain chemicals above threshold quantities and requires facilities to implement 14 elements to prevent accidental releases.

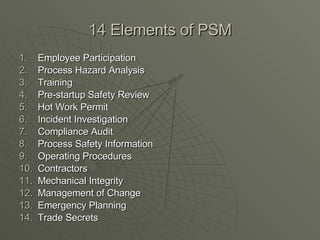

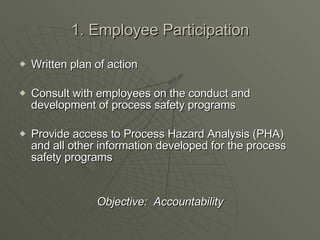

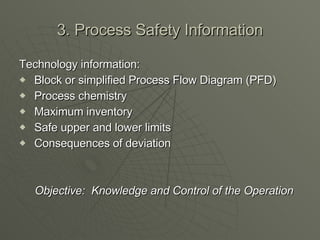

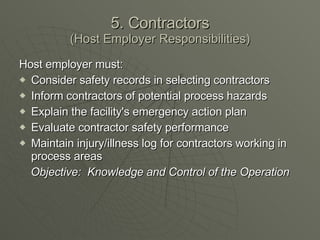

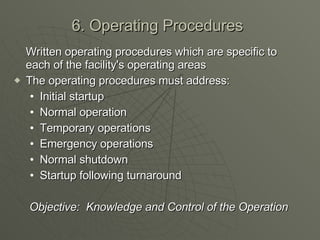

2) The 14 elements include procedures for employee participation, process hazard analysis, operating procedures, contractor management, emergency planning, and compliance audits.

3) The goal of the PSM standard is to ensure facilities have the necessary information to safely manage processes involving highly hazardous chemicals and prevent accidental releases.