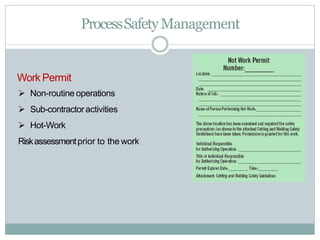

This document discusses process safety management. It defines process safety as preventing incidents that could release hazardous materials or energy. It notes that process safety needs to be considered separately from occupational safety. The document then discusses several key components of process safety management, including process hazard analysis, operating procedures, management of change, employee participation, incident investigation, emergency planning and response, and compliance audits. It provides details on what each component involves, such as developing written procedures for ongoing integrity of process equipment under mechanical integrity. Standards and guidelines from various organizations are also compared.

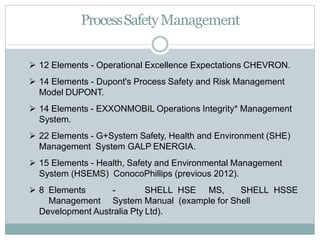

![ 8 Elements - OGP Report 210 EP Forum - Guidelines for the

Development and Application of Health, Safety and Environmental.

13 Elements - Safety & Environmental Management System

(SEMS) - Offshore EU US Bureau of Ocean Energy Management,

Regulation and Enforcement's (BOEMRE) new regulation [30 CFR

250] - API RP 75

ProcessSafetyManagement](https://image.slidesharecdn.com/psmronak17ic58-180903082559/85/Psm-by-Ronak-7-320.jpg)