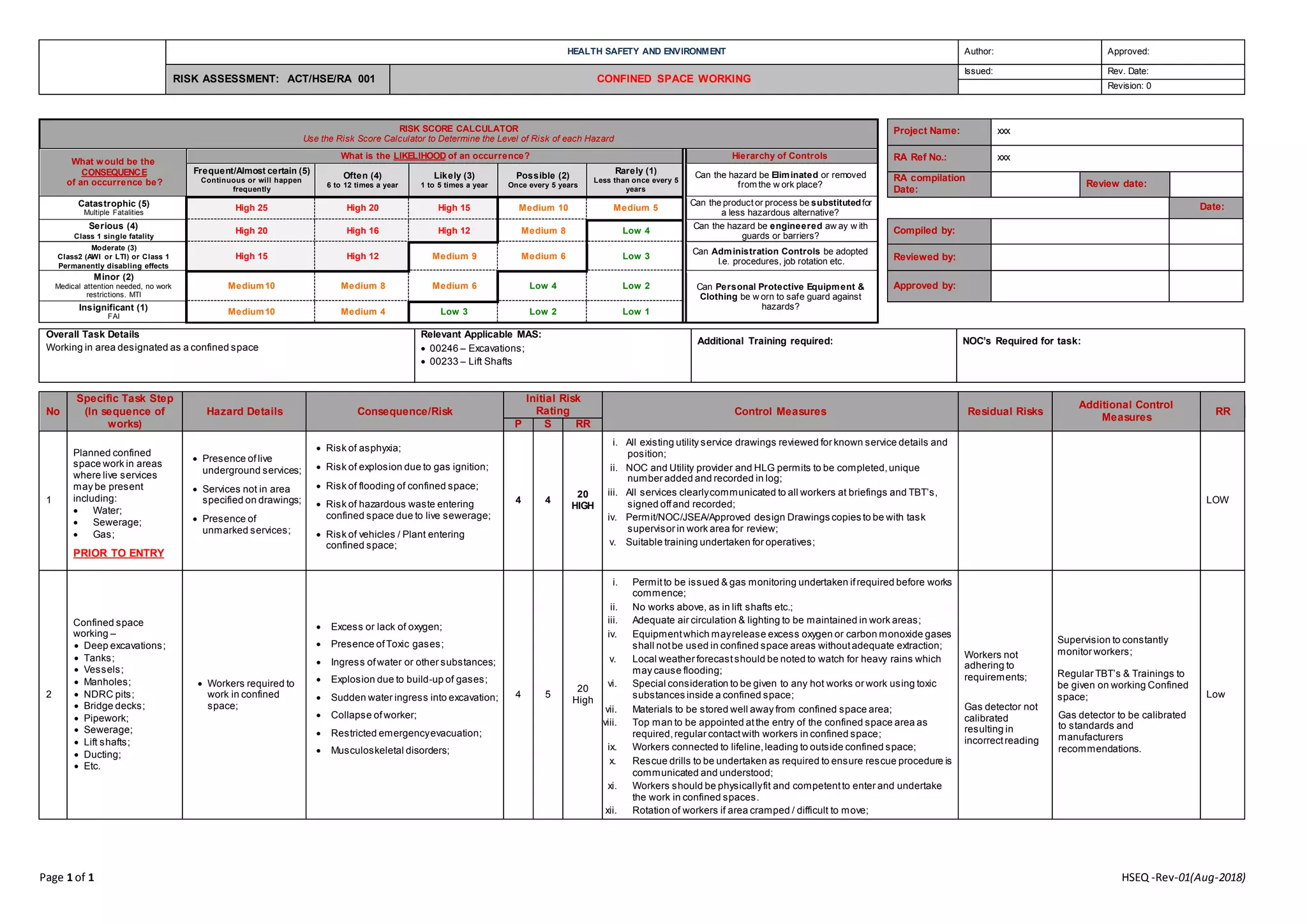

This risk assessment document evaluates the hazards associated with confined space work. It identifies risks such as exposure to live underground utilities, toxic gases, flooding, and restricted evacuation. Initial risks are rated as high. Control measures are outlined to reduce risks, such as obtaining permits, gas monitoring, ventilation, restricted hot works, lifelines, and rescue drills. Residual risks are rated as low when all controls are followed. Additional measures like supervisor monitoring and calibrated gas detectors are recommended to ensure safety protocols are strictly adhered to for confined space work.