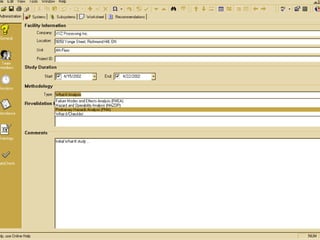

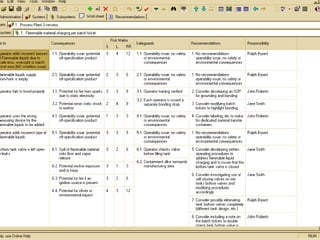

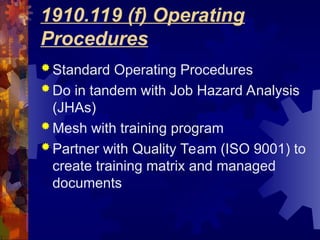

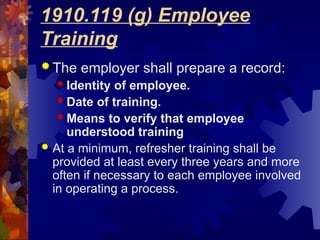

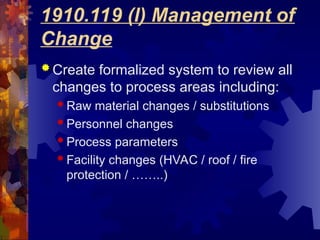

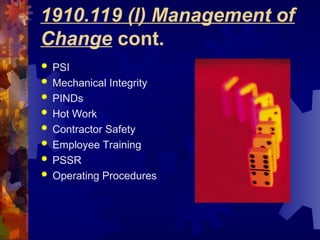

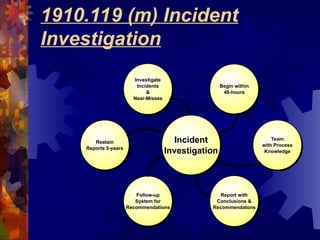

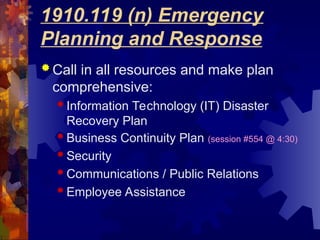

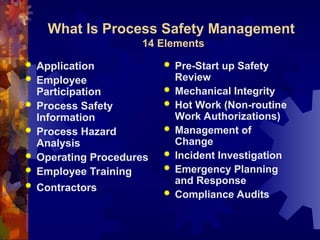

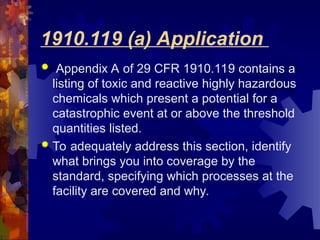

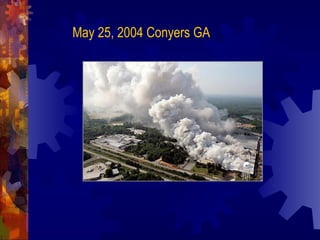

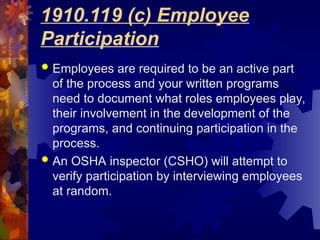

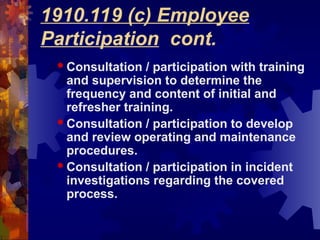

This document provides an overview of Process Safety Management (PSM), highlighting its importance in identifying and controlling process hazards to protect employees and the environment. It outlines the 14 key elements of PSM, such as employee participation, process hazard analysis, and incident investigation, along with compliance requirements under OSHA regulations. Additional guidance is offered for managing changes, training, and preparing for emergencies to ensure a safe working environment.

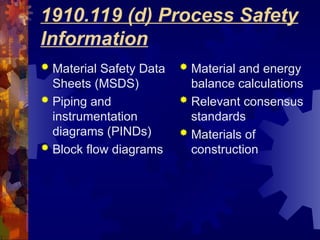

![1910.119 (d) Process Safety

Information cont.

Available to all affected employees [requirement of

1910.119 (c) Employee Participation]

Available for Process Hazard Analysis and

revalidations [requirement of 1910.119 (e) Process

Hazard Analysis]

So auditors and CSHOs can find everything!](https://image.slidesharecdn.com/asse04processsafetymanagement-240910173939-5e7c949c/85/ASSE_00004_Process_Safety_Management-ppt-12-320.jpg)