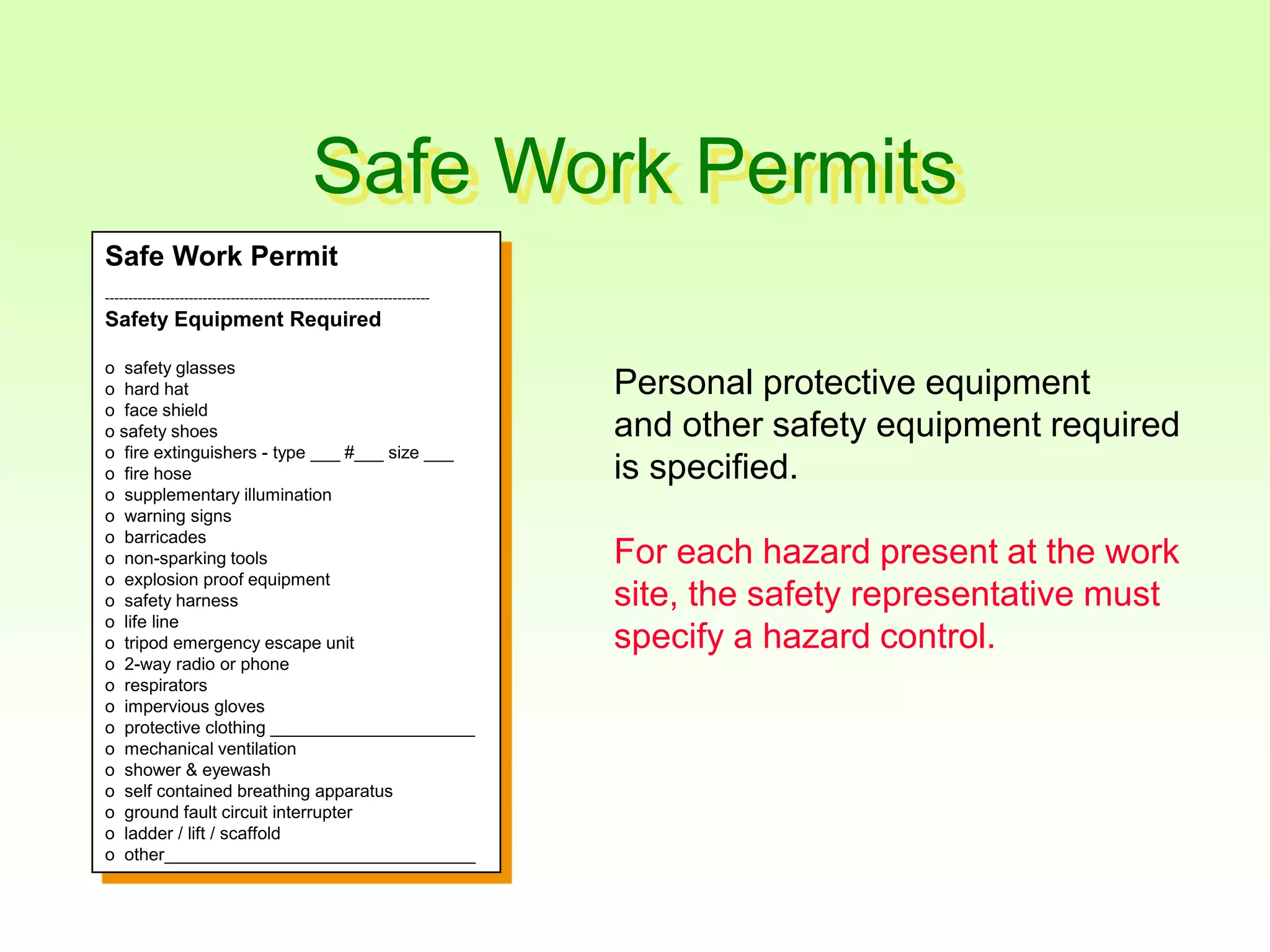

The document discusses safe work permits, which are required for hazardous non-routine jobs. Safe work permits identify hazards, require safety precautions, and must be issued by a qualified individual for jobs like hot work, confined space entry, excavations, and other potentially dangerous activities. The permits are written for specific jobs and time periods, list required safety equipment and checks, and must be reviewed and approved by supervisors and managers.