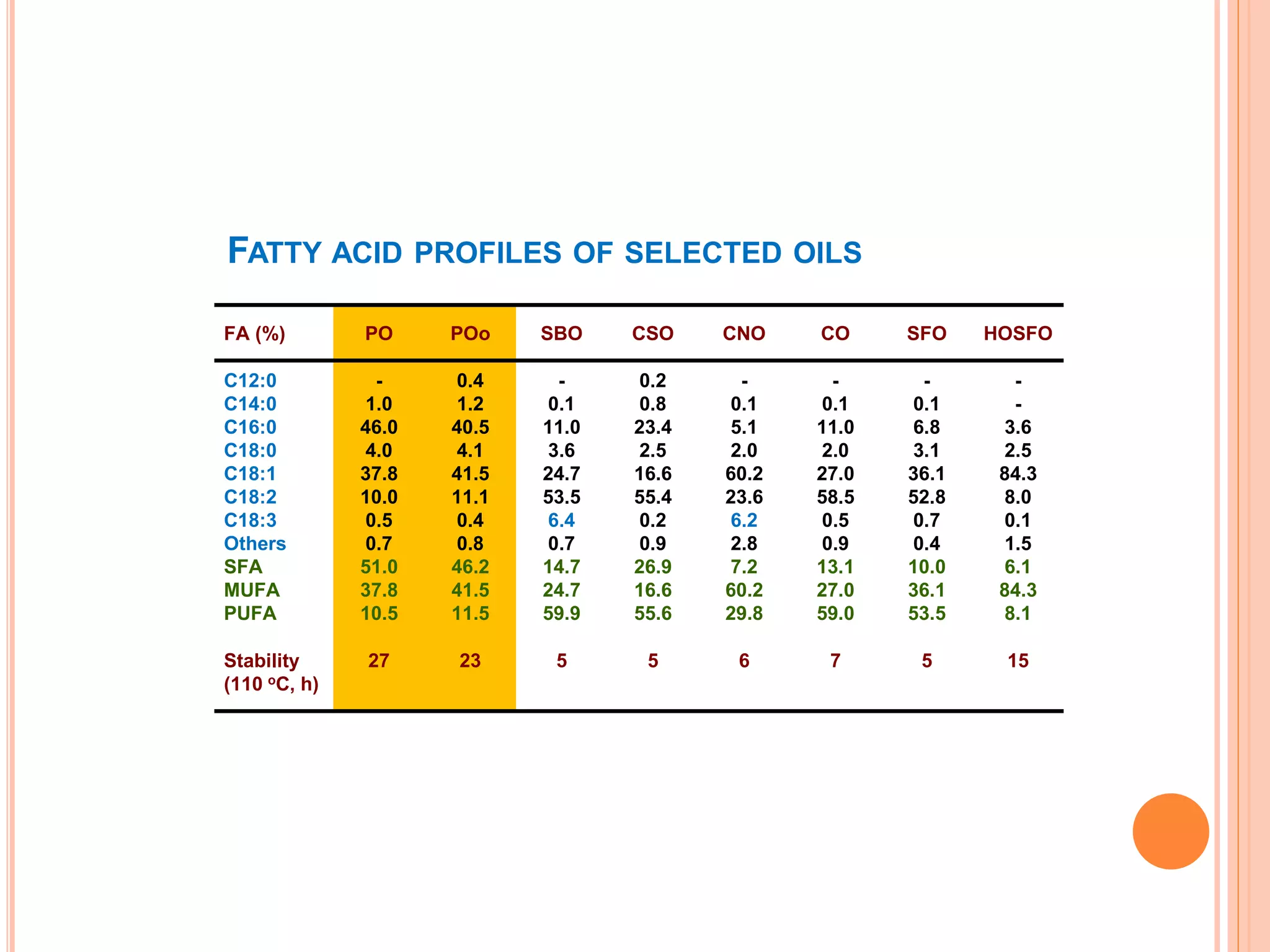

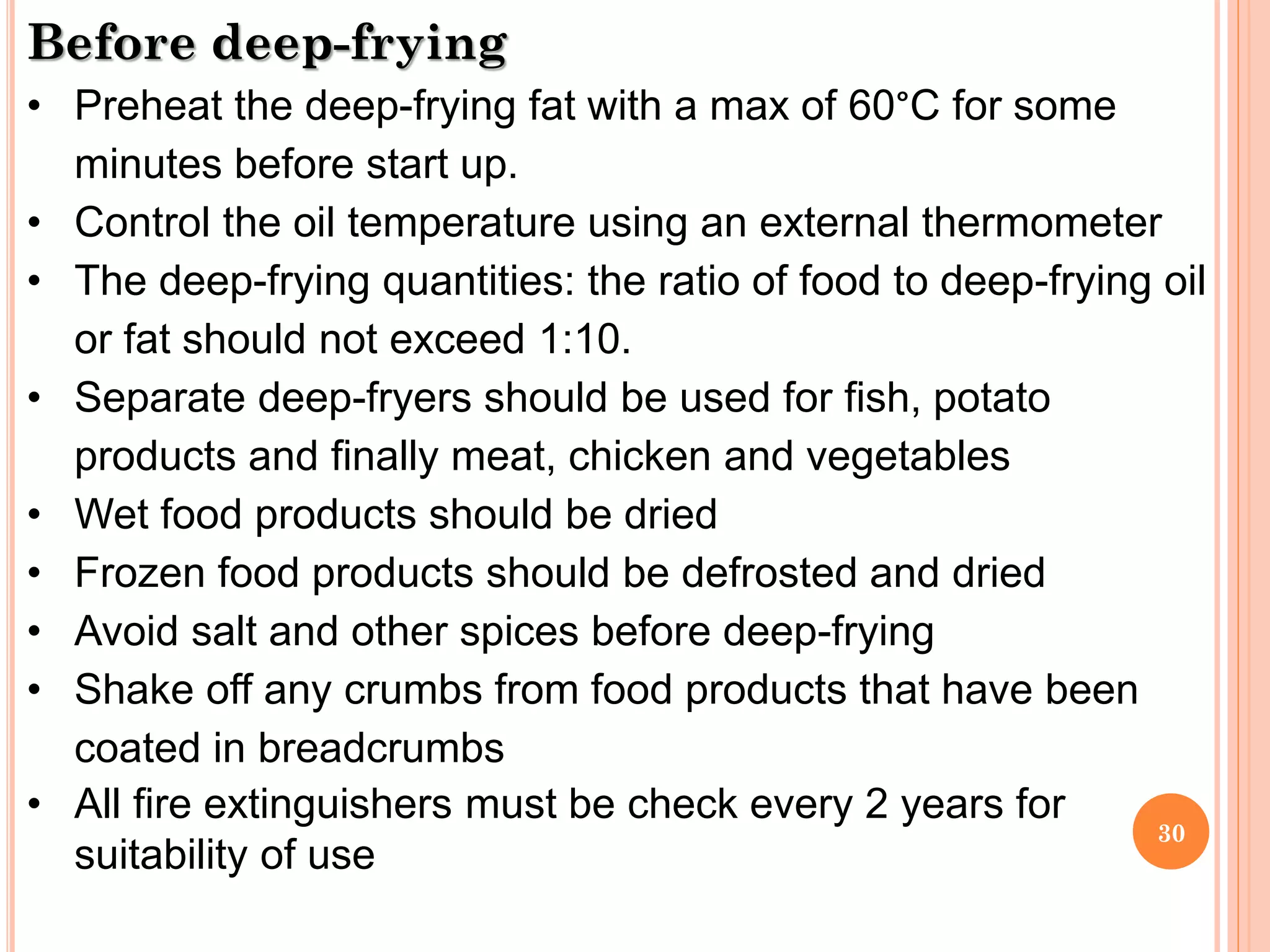

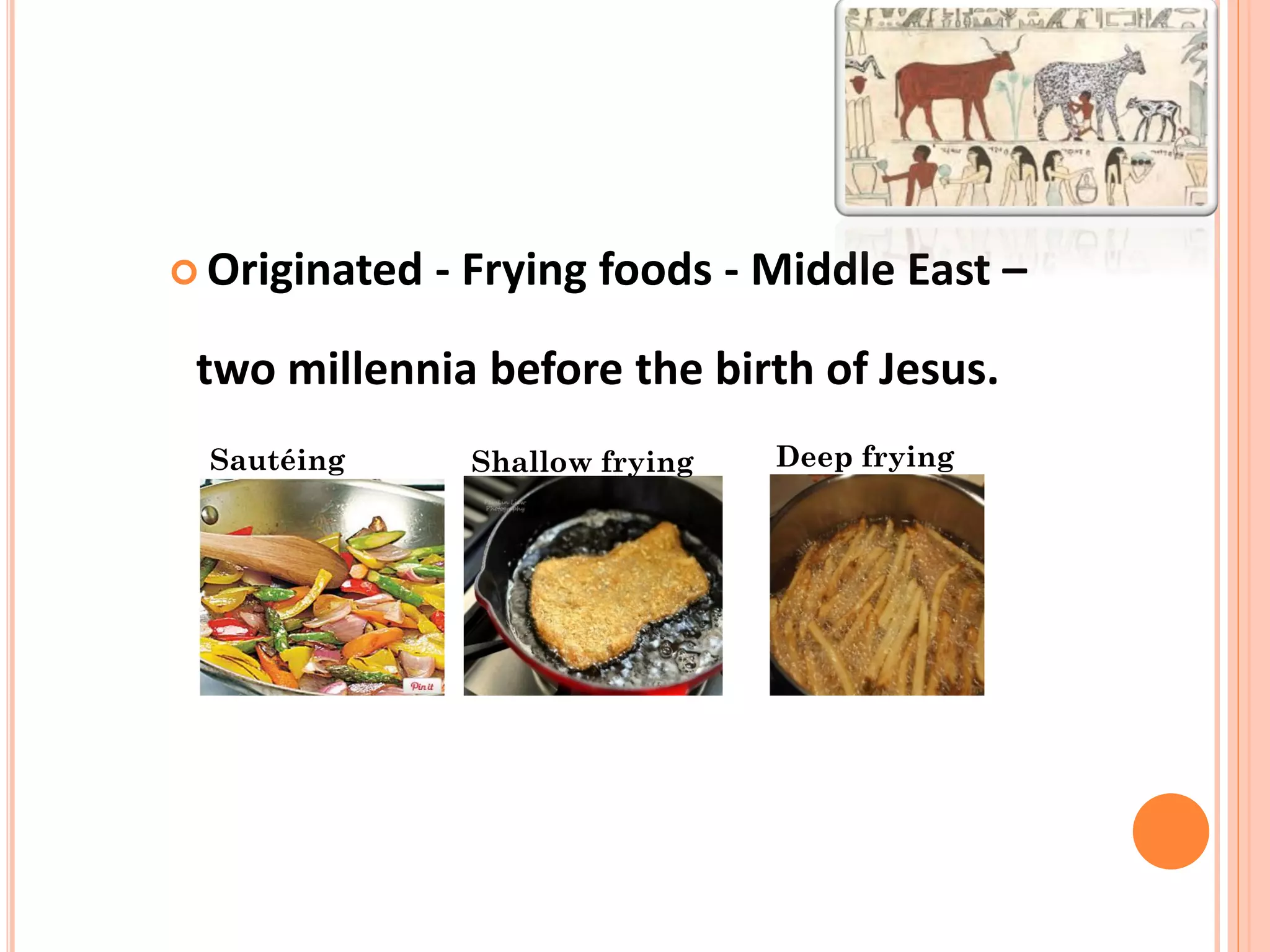

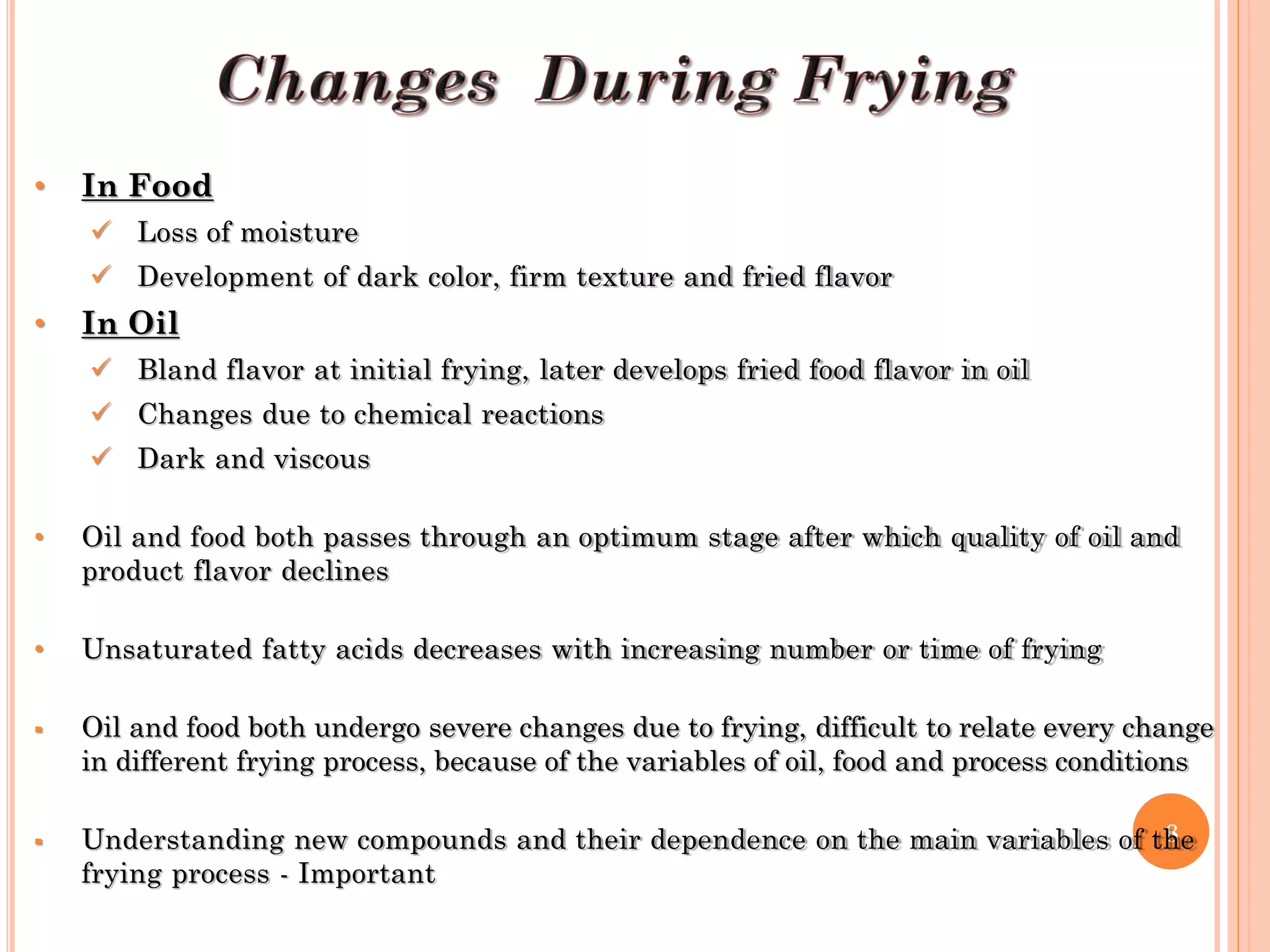

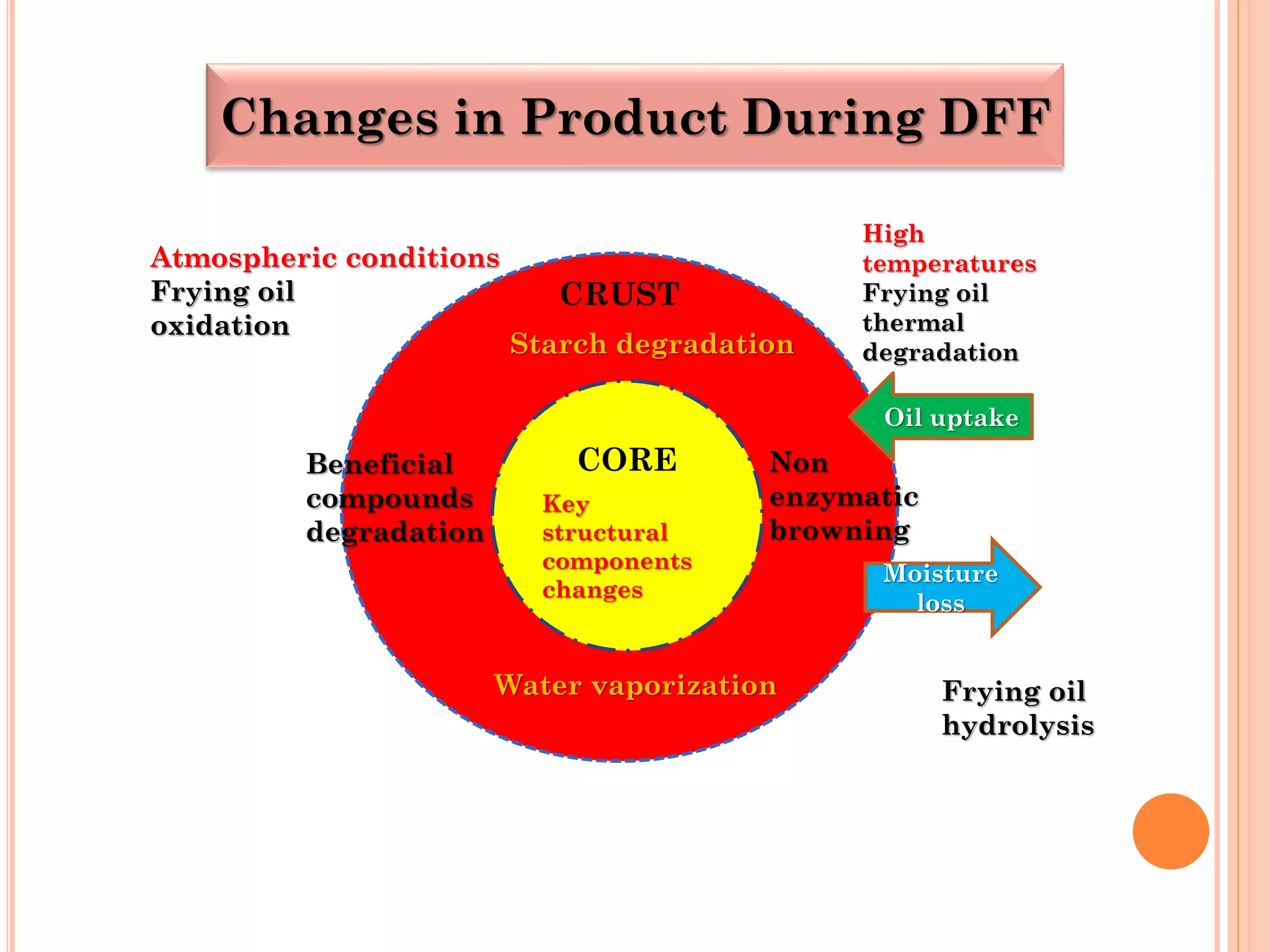

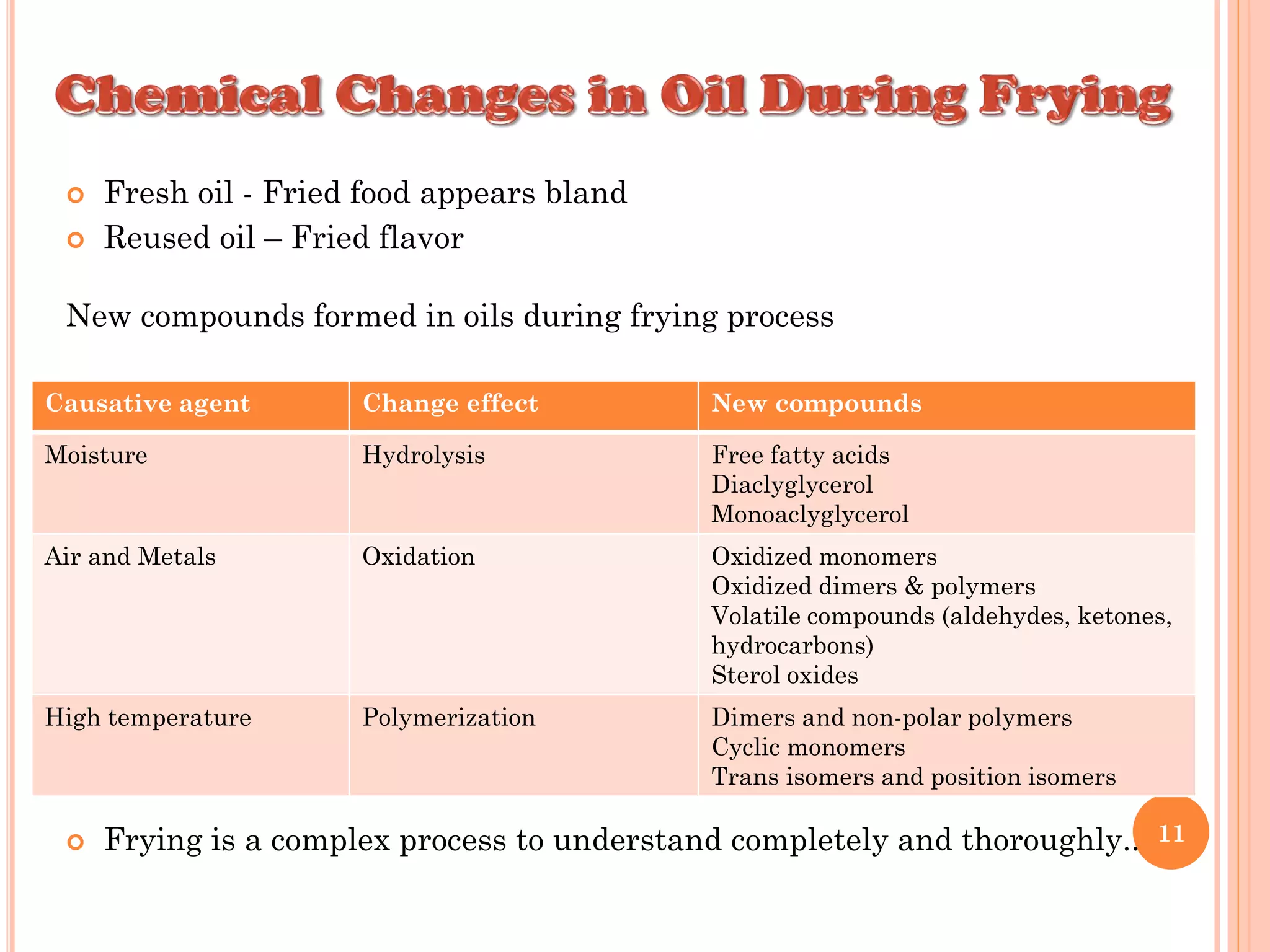

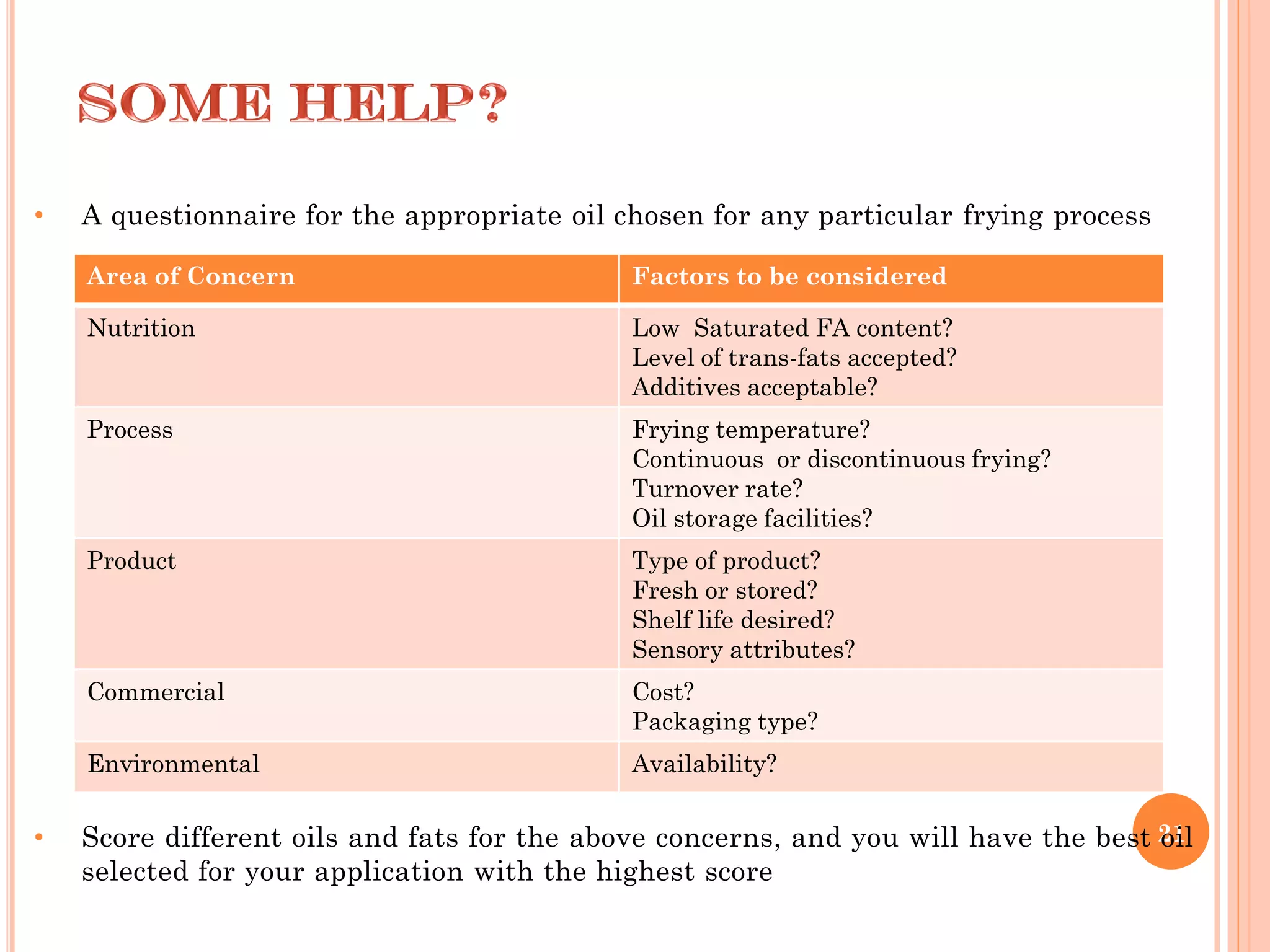

The document summarizes information about deep frying processes and frying oil selection and quality. It discusses the common methods of shallow frying, deep frying, and par-frying. During deep frying, undesirable chemical changes can occur in both the food and oil that affect quality. The stability and fatty acid composition of the oil influences its suitability for frying. In Egypt, common frying oils include cottonseed, soybean, sunflower, and palm olein oils. Maintaining oil quality involves monitoring parameters like free fatty acids and replacing oil before degradation.

![One of the usual ways for increasing the oxidative

stability of soft oils (soybean and sunflower) is

blending with other oils that have less unsaturated

compounds and high oxidative stability [Chu & Kung, 1998].

Palm olein is one of the suitable oils for blending

with other sensitive oils.](https://image.slidesharecdn.com/optimumuseoffryingoilshurghadadradel-170504095404/75/Optimum-use-of-frying-oils-26-2048.jpg)