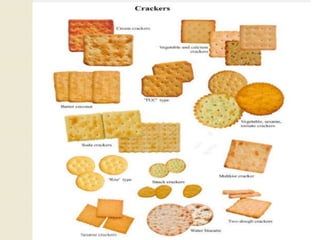

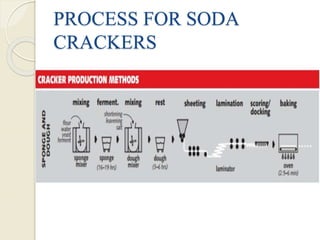

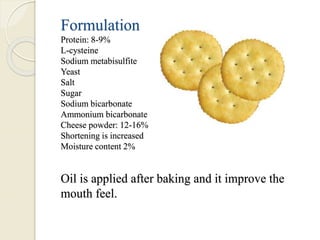

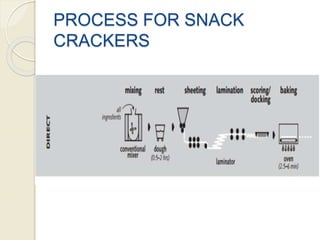

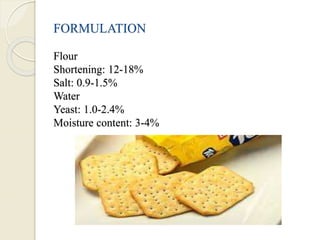

Crackers are baked products known for their crispy texture and savory flavor, first created in 1792. They have holes, or docking holes, to allow air to escape during baking, preventing bubbles from bursting and ensuring a flat, crispy final product. The document outlines three main types of crackers: soda crackers, snack crackers, and cream crackers, each with distinct ingredients and preparation processes.