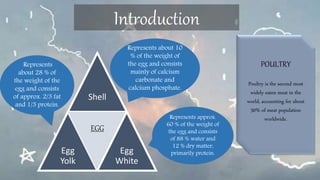

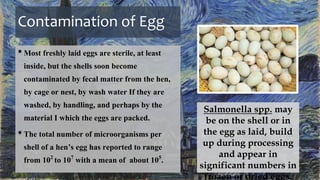

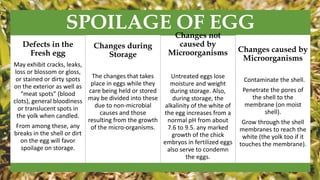

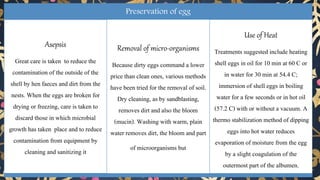

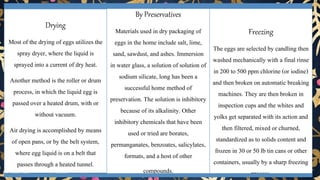

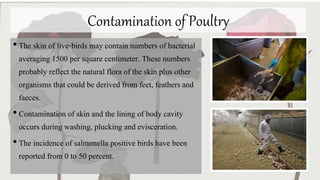

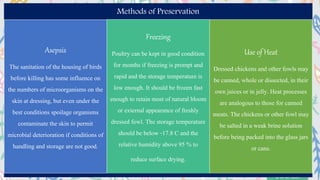

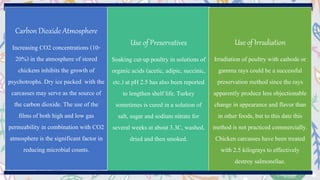

This document discusses contamination, spoilage, and preservation of eggs and poultry. It begins with an introduction to egg anatomy and notes that poultry is the second most consumed meat worldwide. It then discusses sources and types of contamination for eggs and poultry. Spoilage factors and mechanisms for both are described. Various preservation methods for eggs are outlined, including asepsis, removal of microorganisms, use of heat, drying, preservatives, and freezing. Preservation methods for poultry include asepsis, freezing, use of heat, carbon dioxide atmospheres, use of preservatives, and irradiation. References are listed at the end.