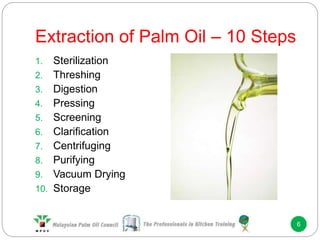

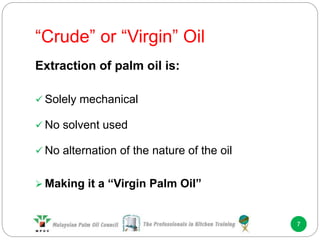

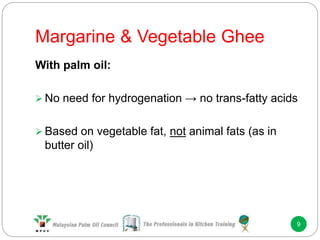

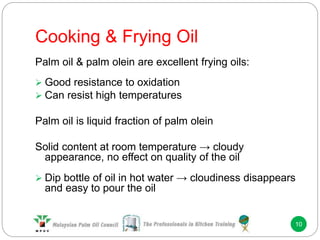

The document discusses the history, cultivation, extraction, and applications of Malaysian palm oil, highlighting its significance as a versatile cooking oil with various food applications. It presents nutritional benefits, techno-economic advantages, and safety measures related to frying with palm oil, emphasizing its health properties, affordability, and stable supply. The document concludes by addressing industry trends favoring palm oil amidst growing demand for vegetable fats.