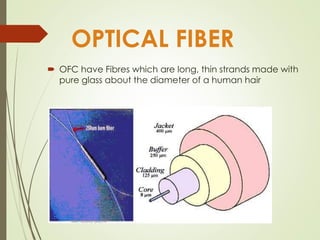

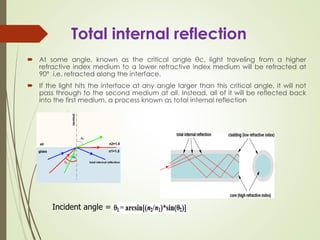

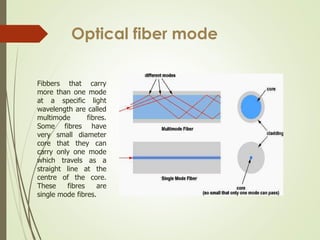

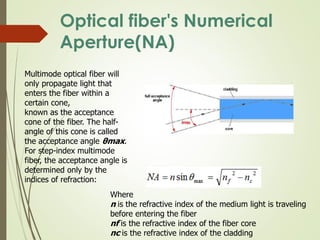

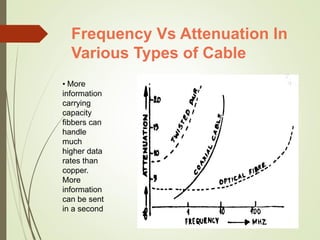

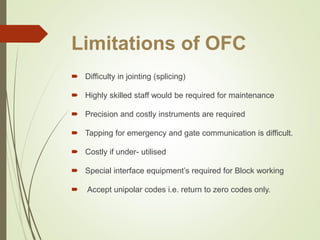

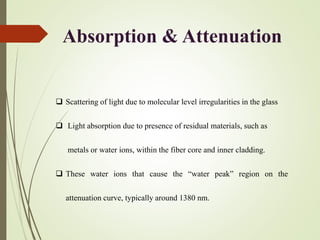

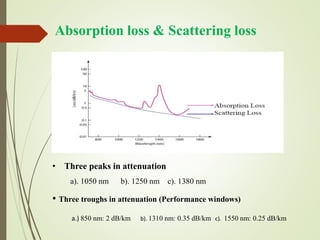

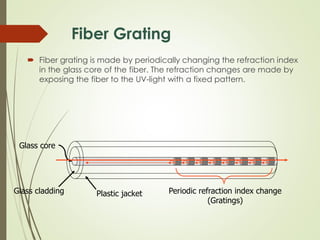

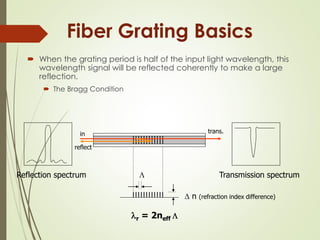

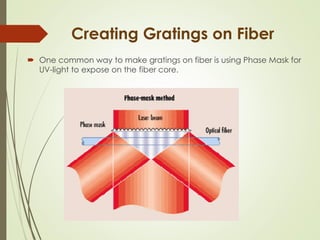

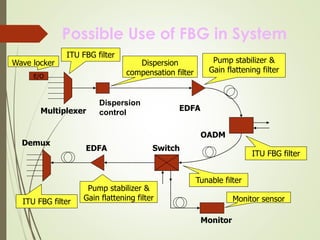

The document discusses optical fibers, including their structure, modes, and the principles of total internal reflection. It highlights the advantages of optical fibers over copper, their applications, and the challenges of maintenance and jointing. Additionally, it covers fiber bragg gratings (FBGs), their creation, characteristics, and current applications in various optical systems.