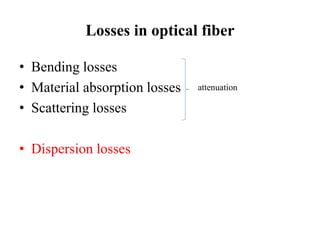

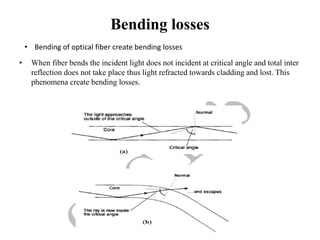

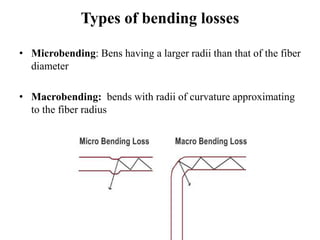

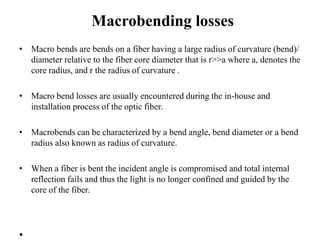

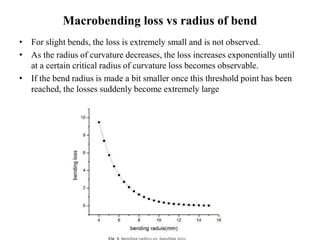

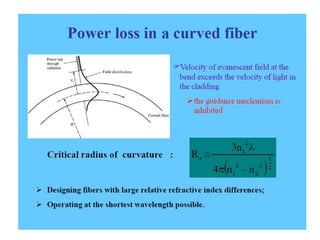

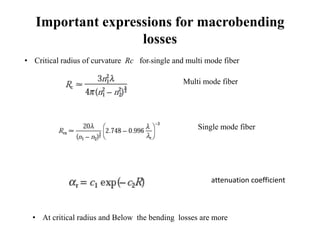

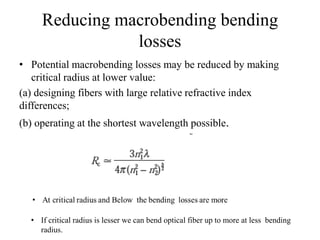

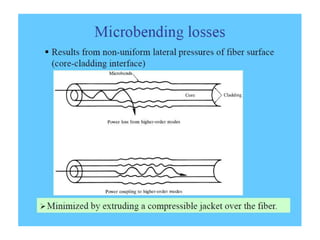

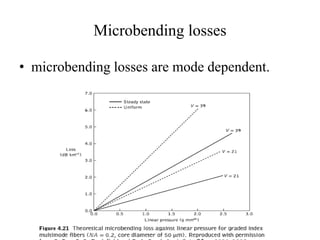

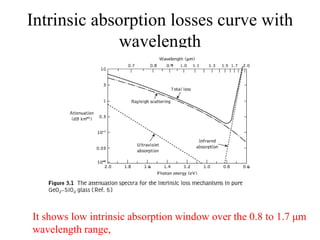

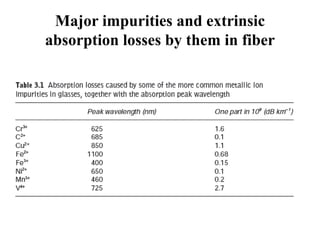

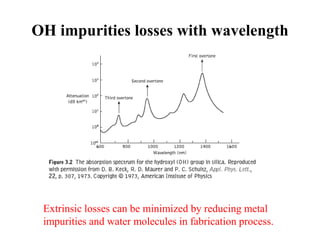

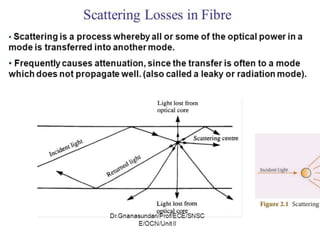

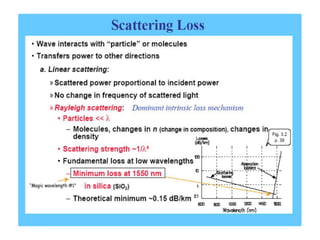

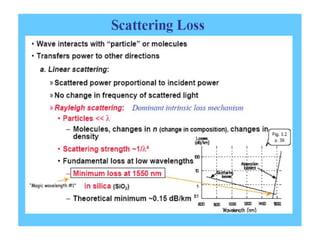

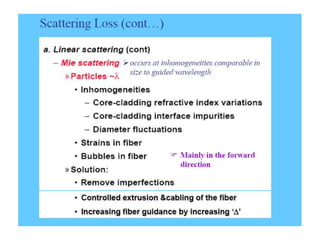

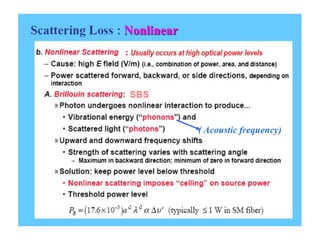

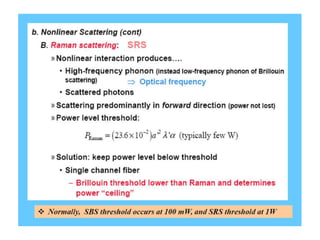

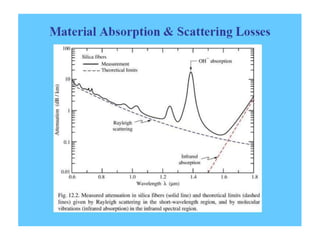

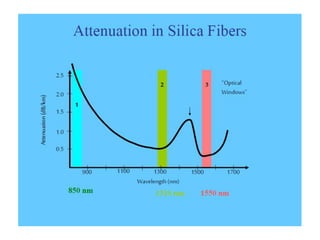

Losses in optical fibers can occur due to bending, material absorption, scattering, and dispersion. The main types of bending losses are microbending from small bends and macrobending from larger radius bends. Material absorption losses include intrinsic losses from the fiber material and extrinsic losses from impurities. Proper fiber design and coating can help minimize bending and material absorption losses to improve signal transmission.