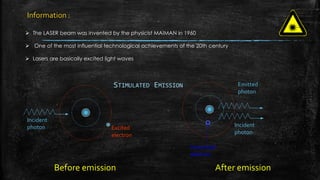

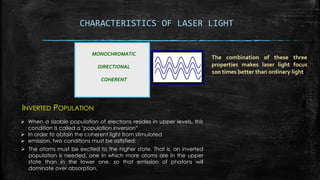

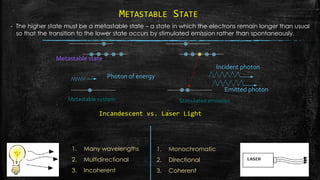

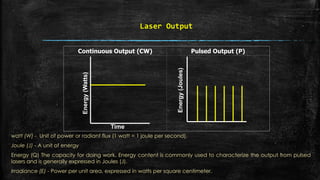

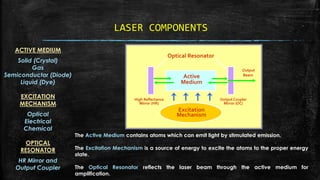

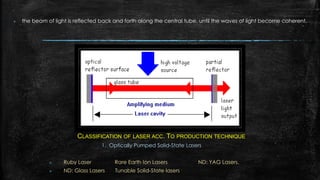

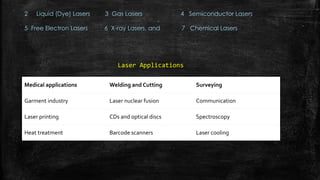

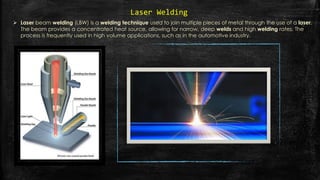

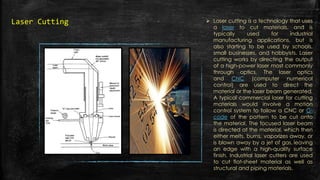

The document presents an overview of laser technology, detailing its invention, characteristics, and applications. It discusses the principles of laser operation, including population inversion, metastable states, and types of lasers based on production techniques. Additionally, the document highlights various applications of lasers in fields like welding, cutting, and communication.