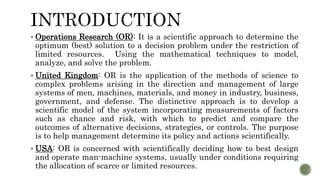

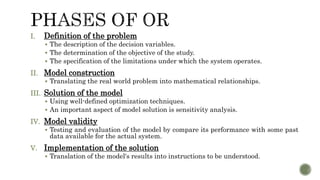

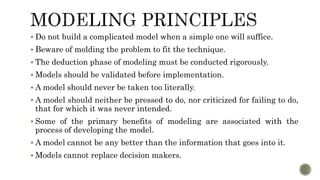

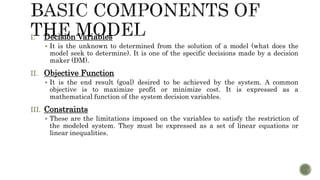

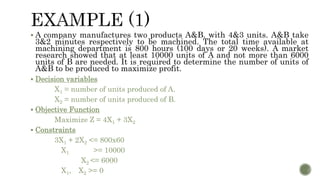

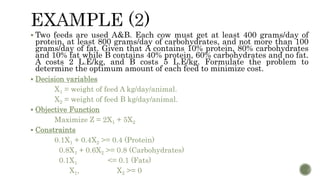

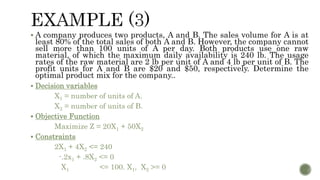

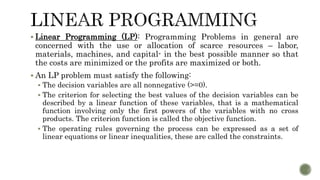

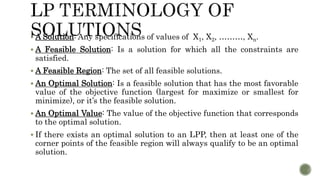

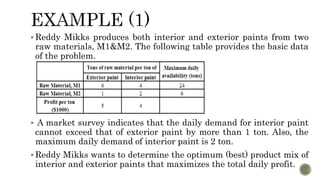

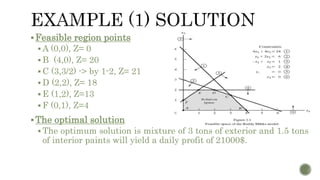

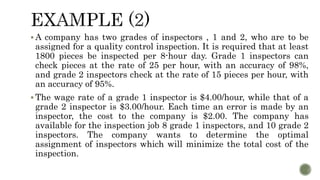

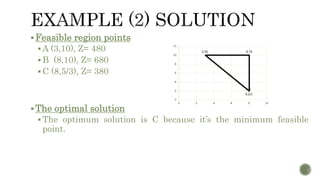

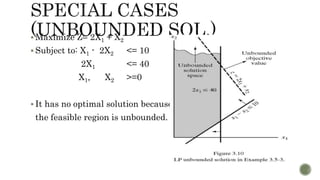

The document discusses operations research and linear programming. It defines operations research as a scientific approach to determine optimal solutions to decision problems with limited resources. Linear programming problems have decision variables, an objective function to maximize or minimize, and constraints. An optimal solution is a feasible solution that gives the most favorable objective function value. Graphical methods can find the optimal solution by determining the feasible region and optimal point.