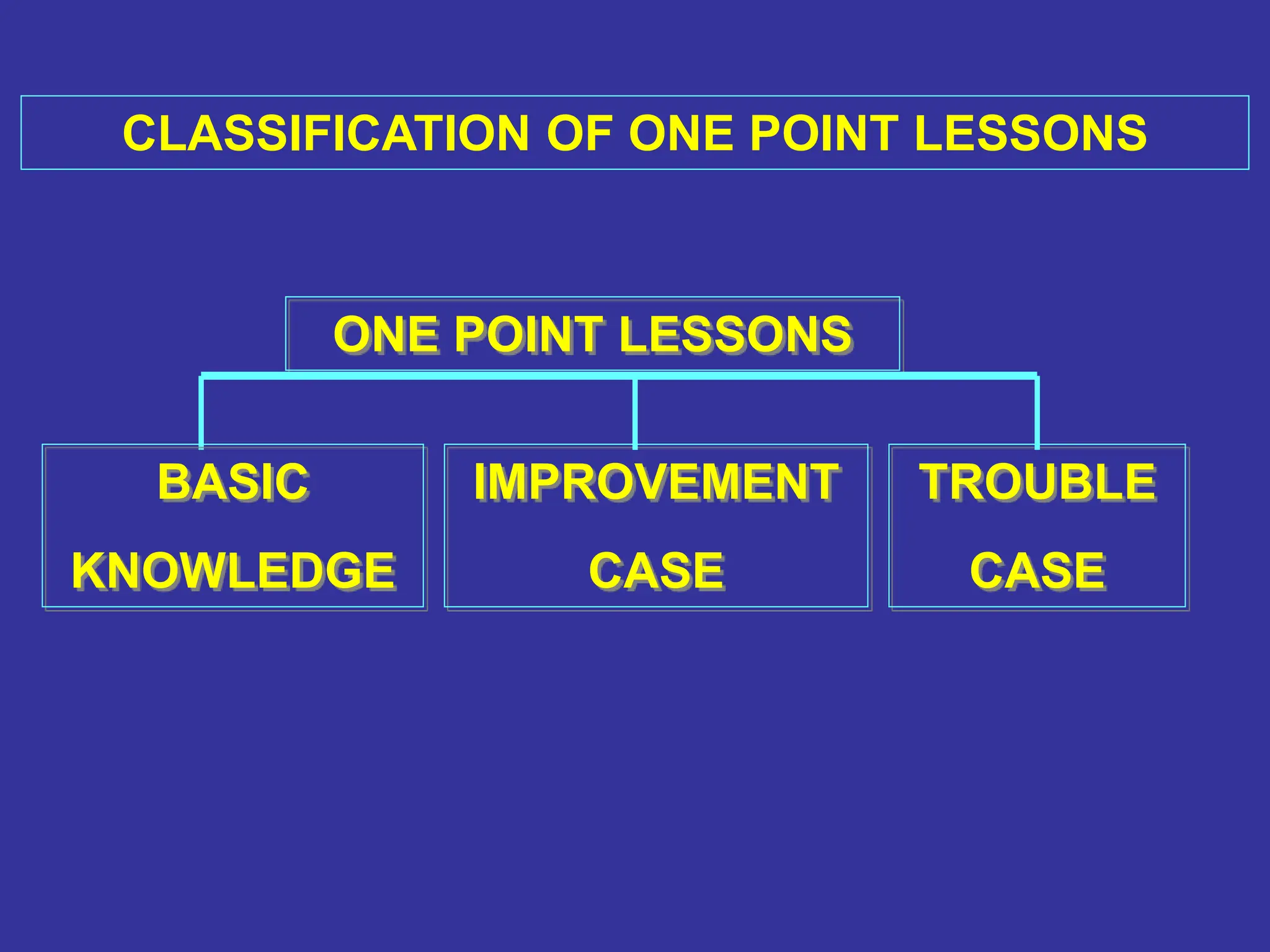

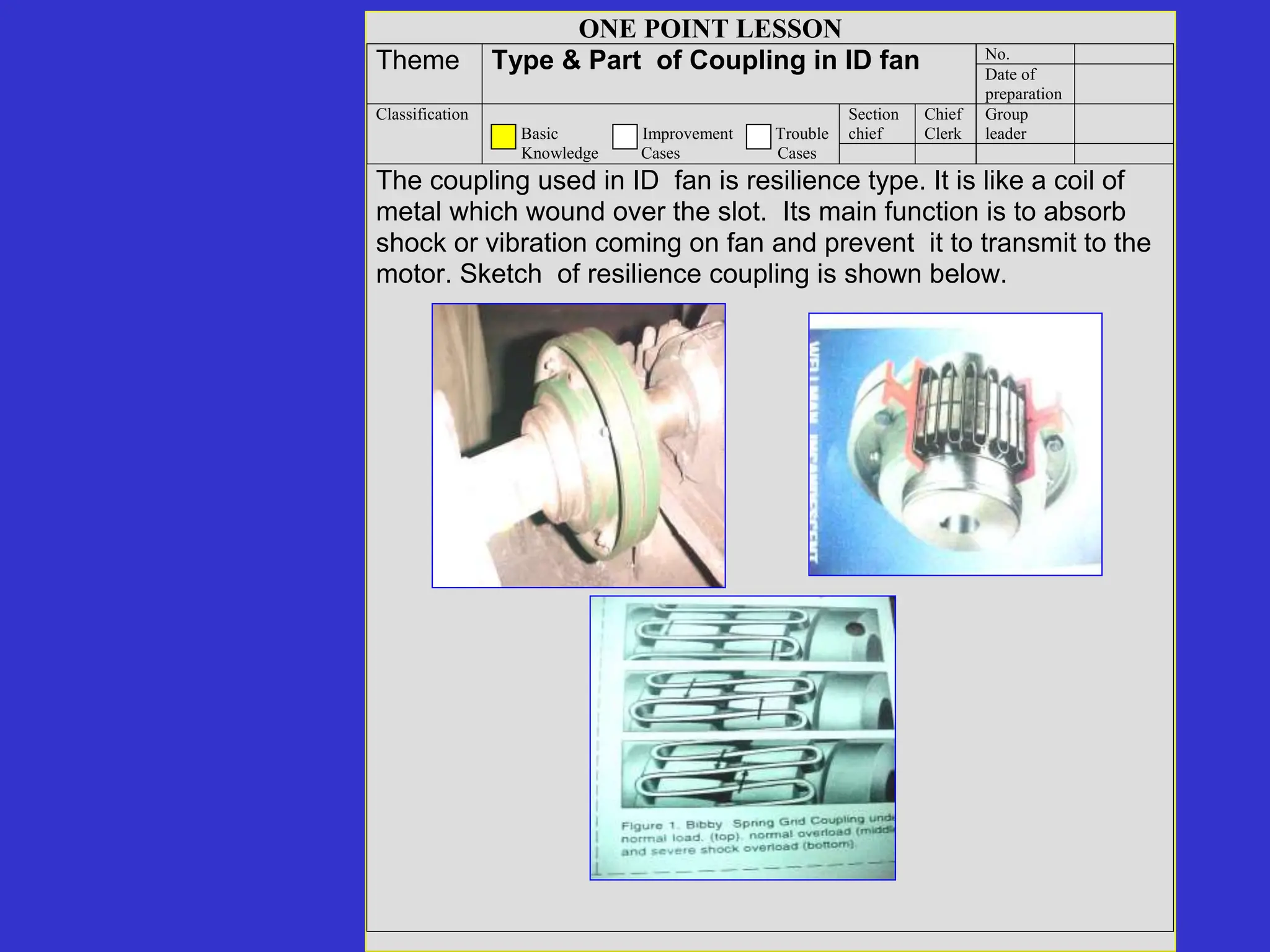

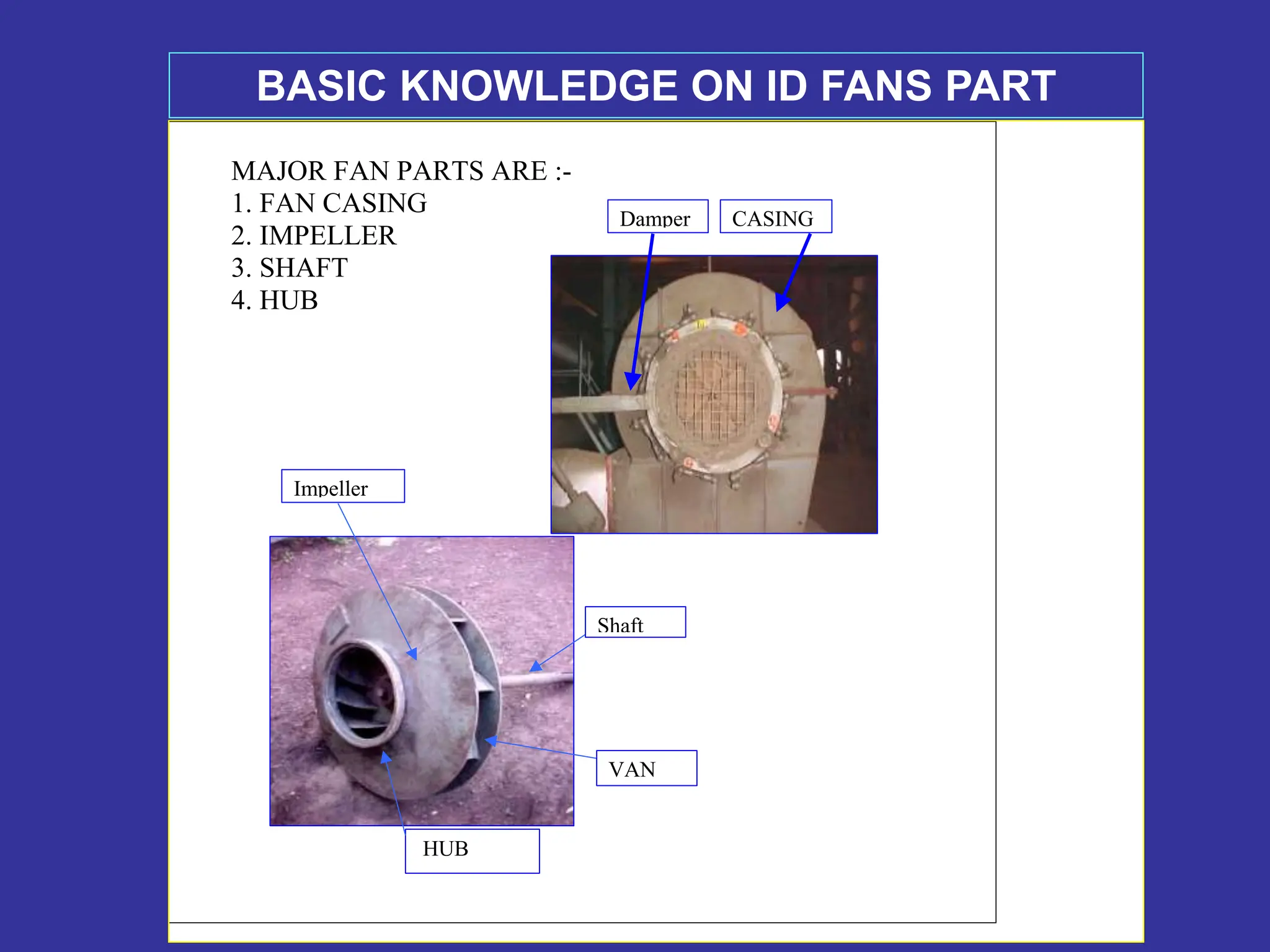

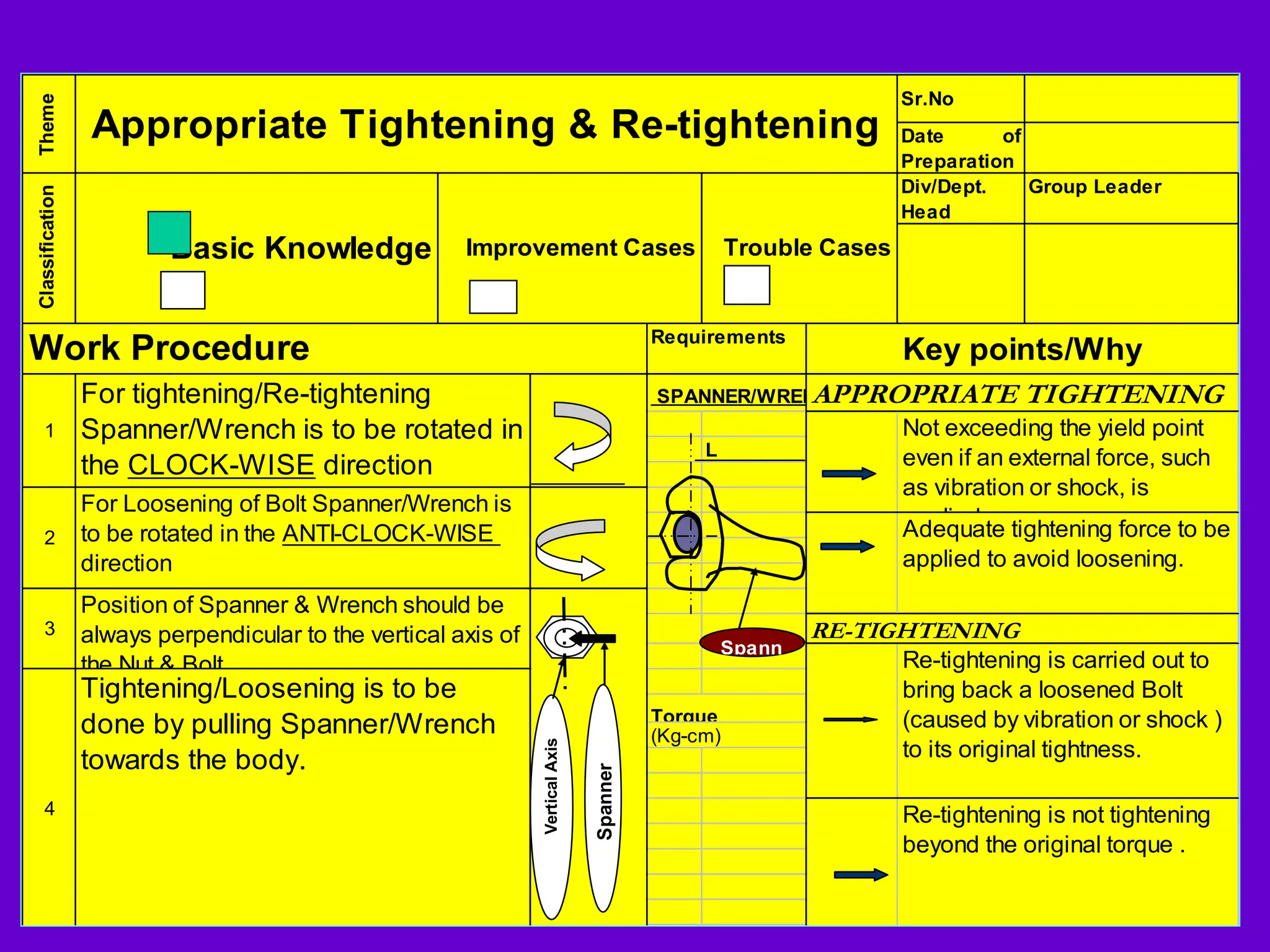

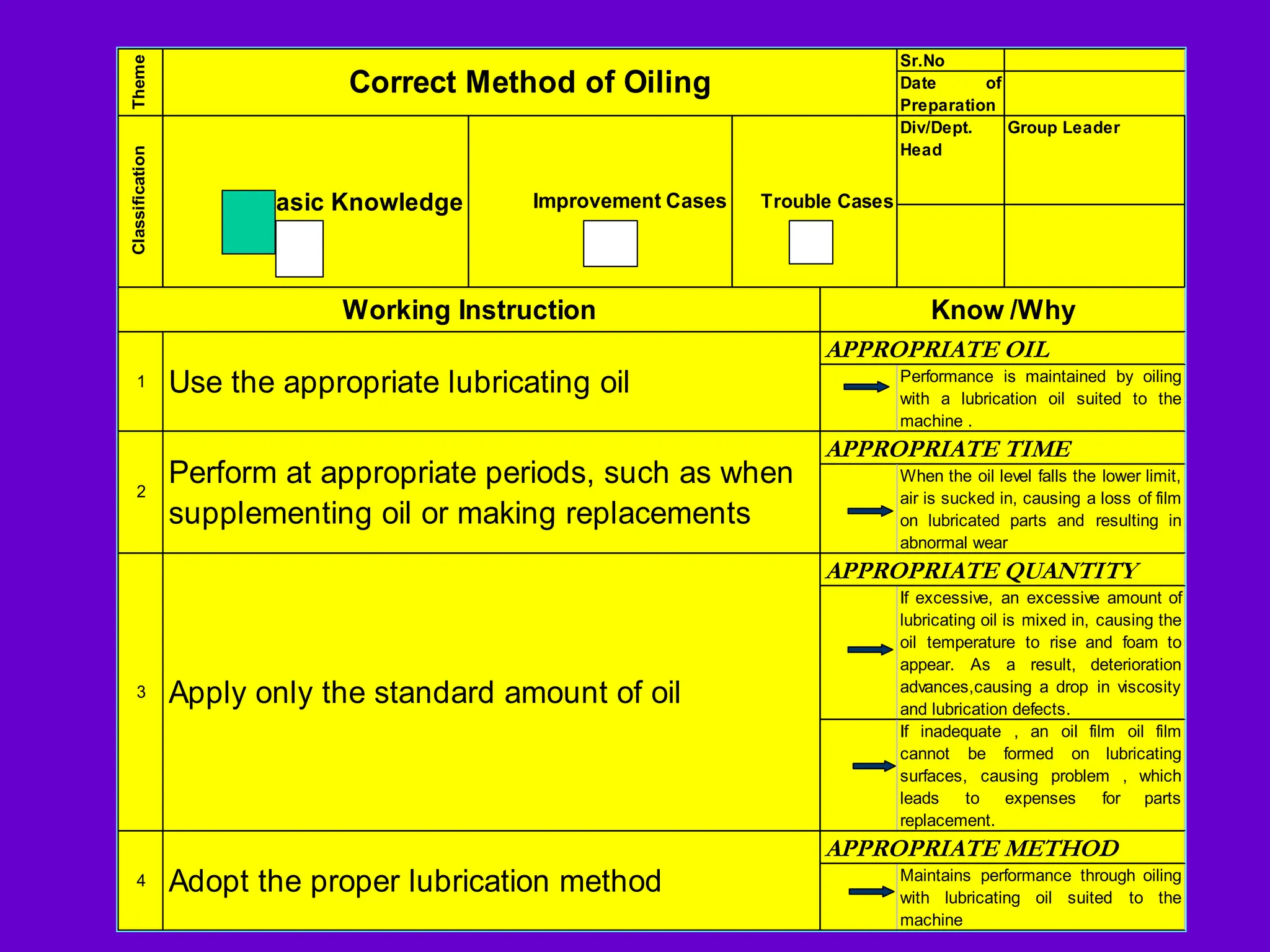

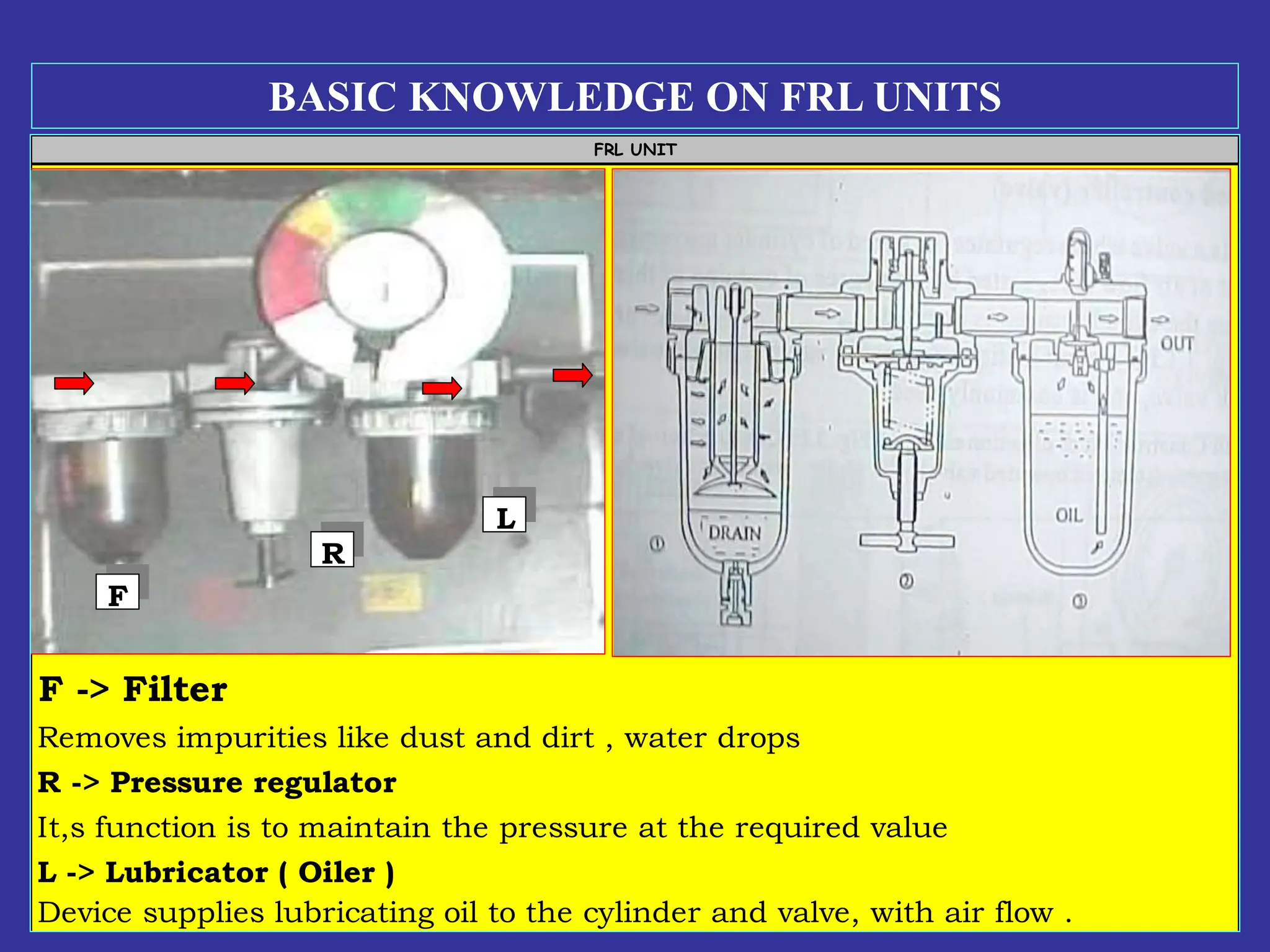

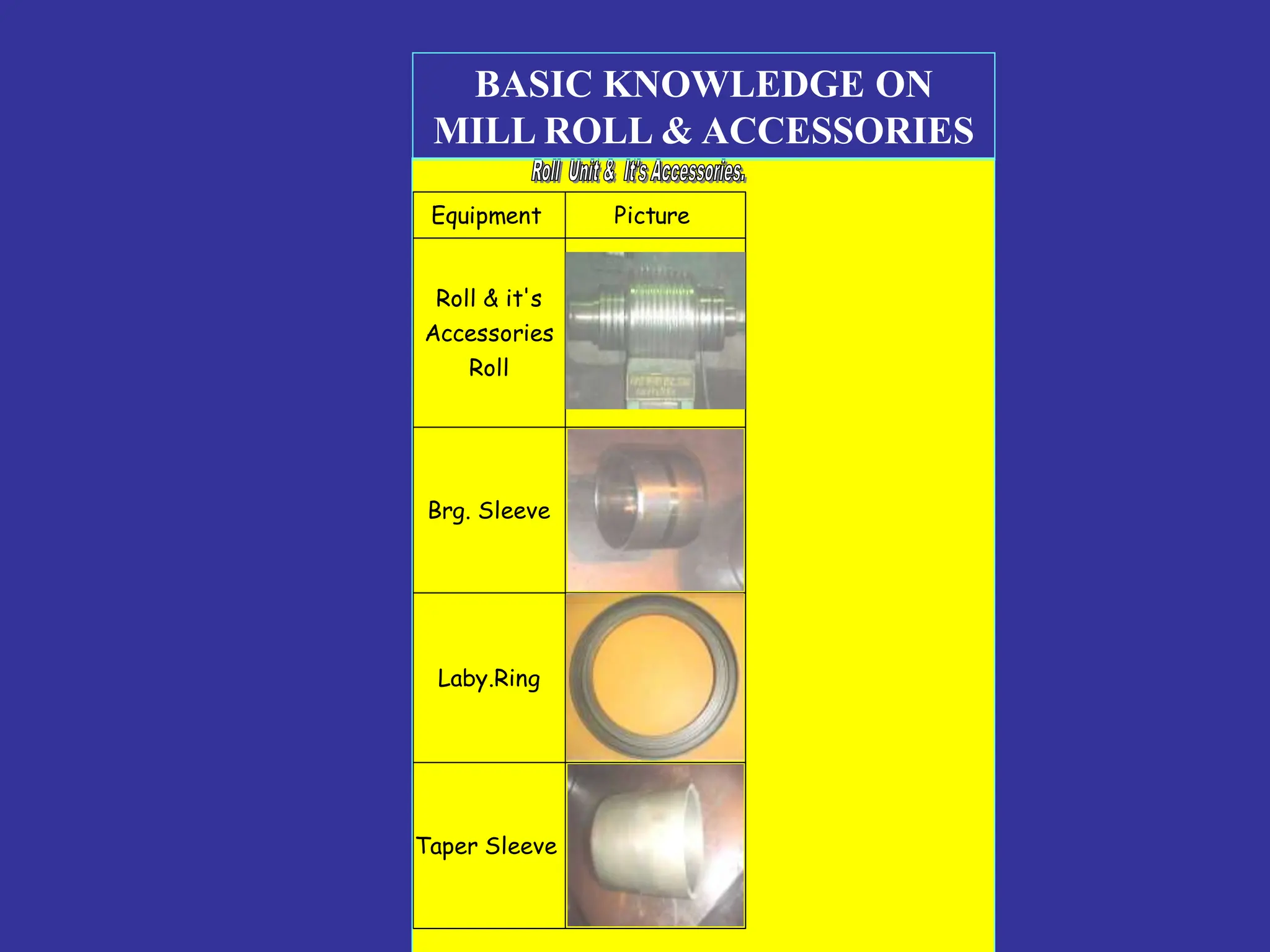

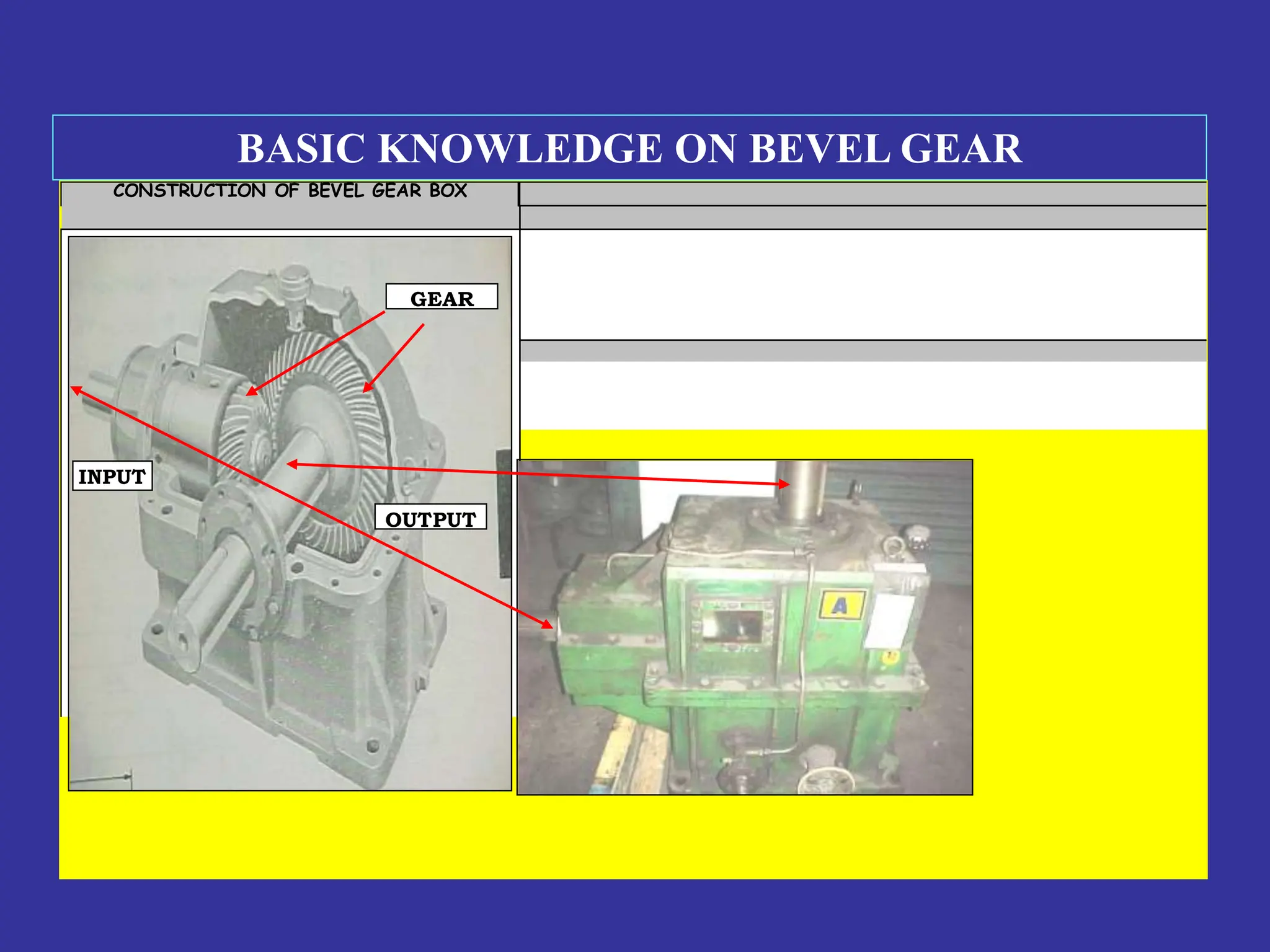

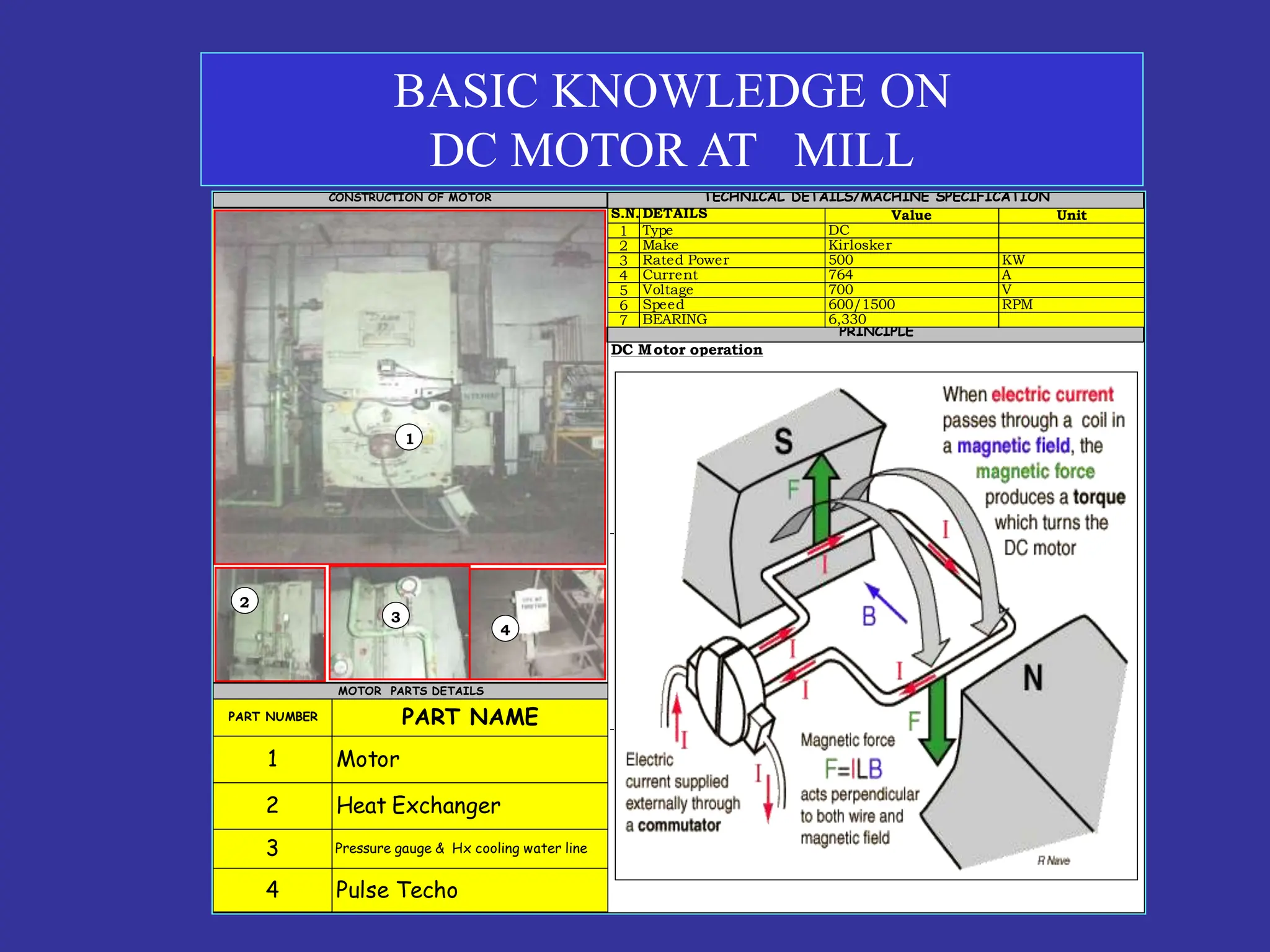

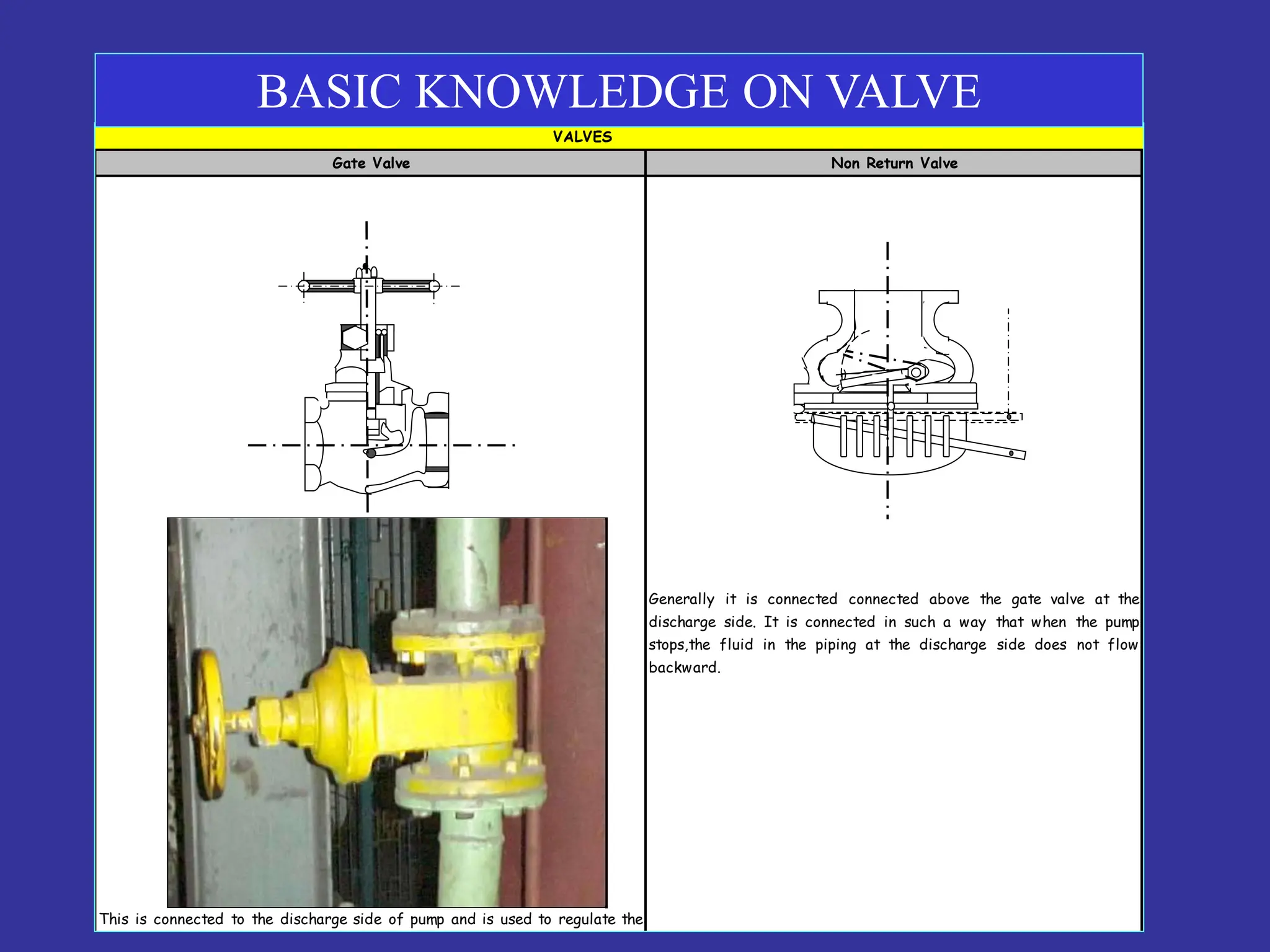

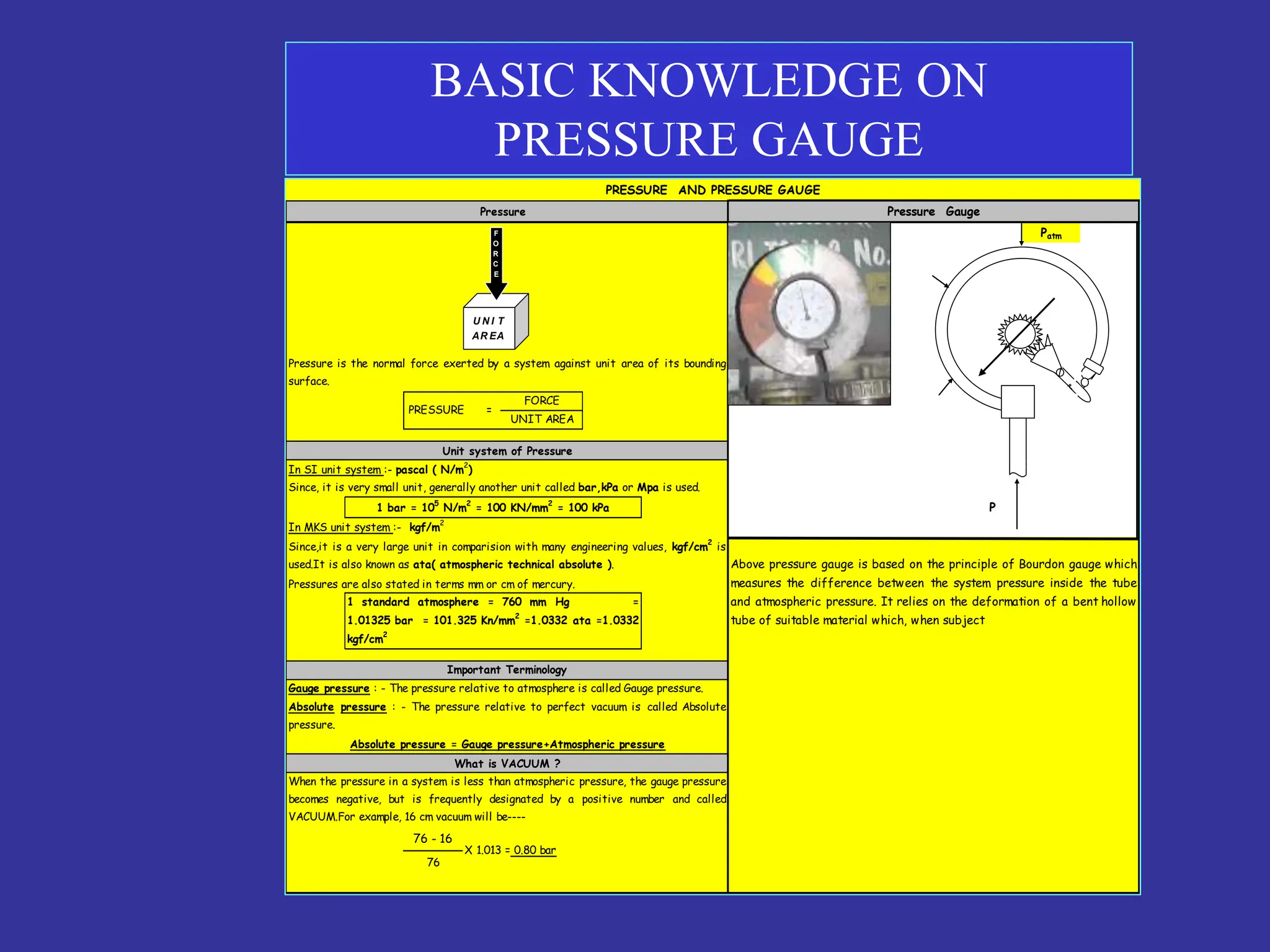

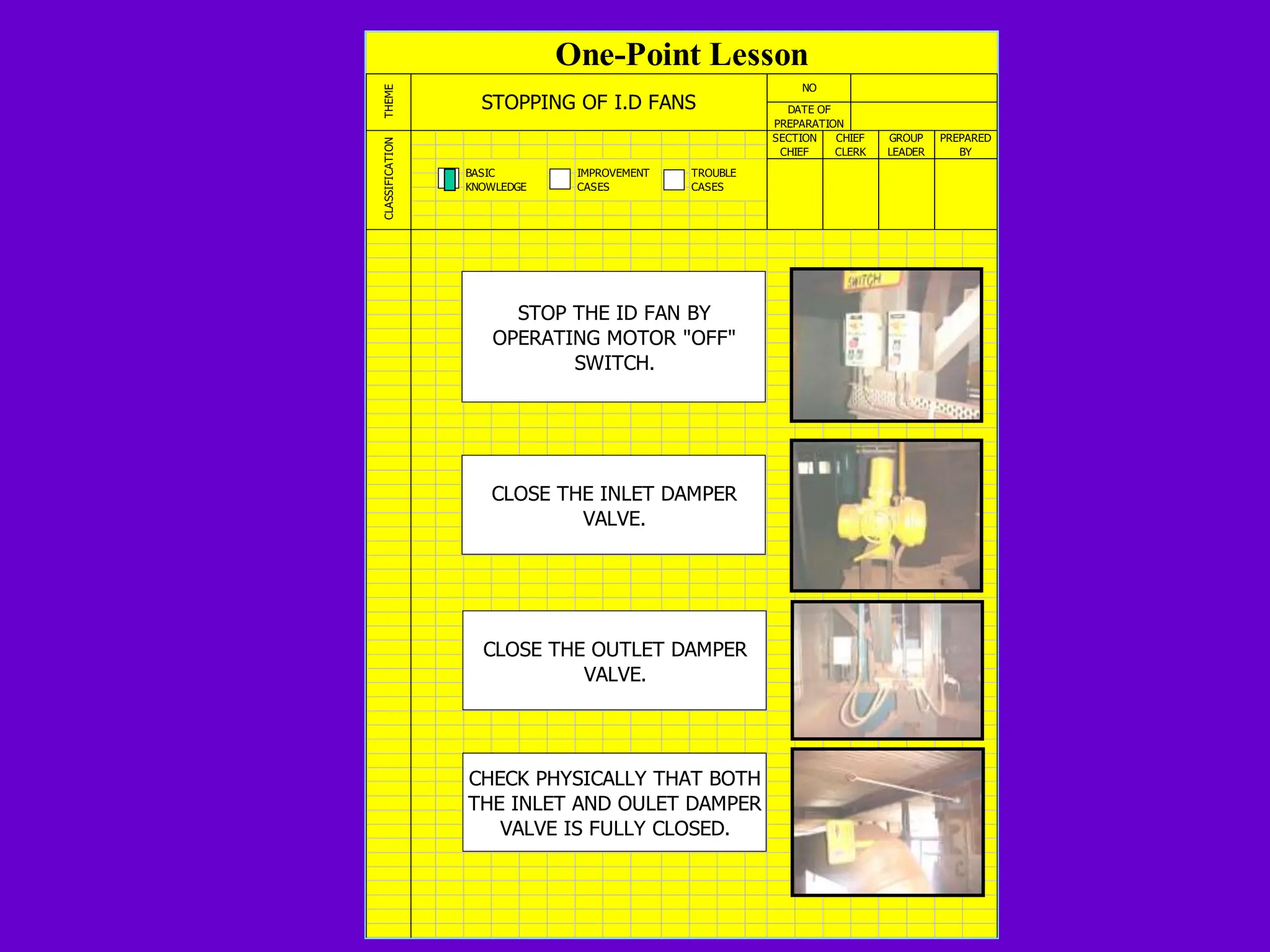

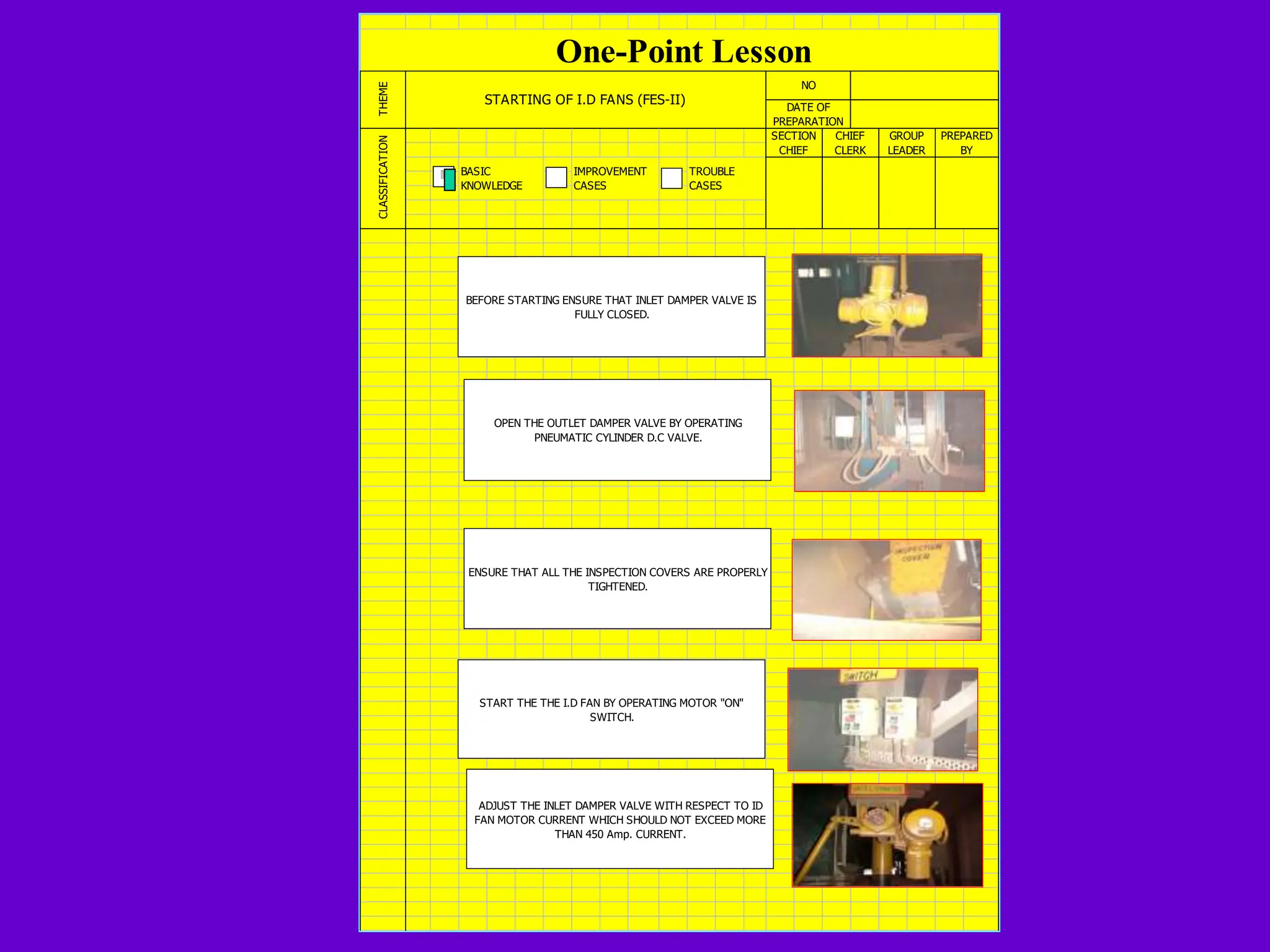

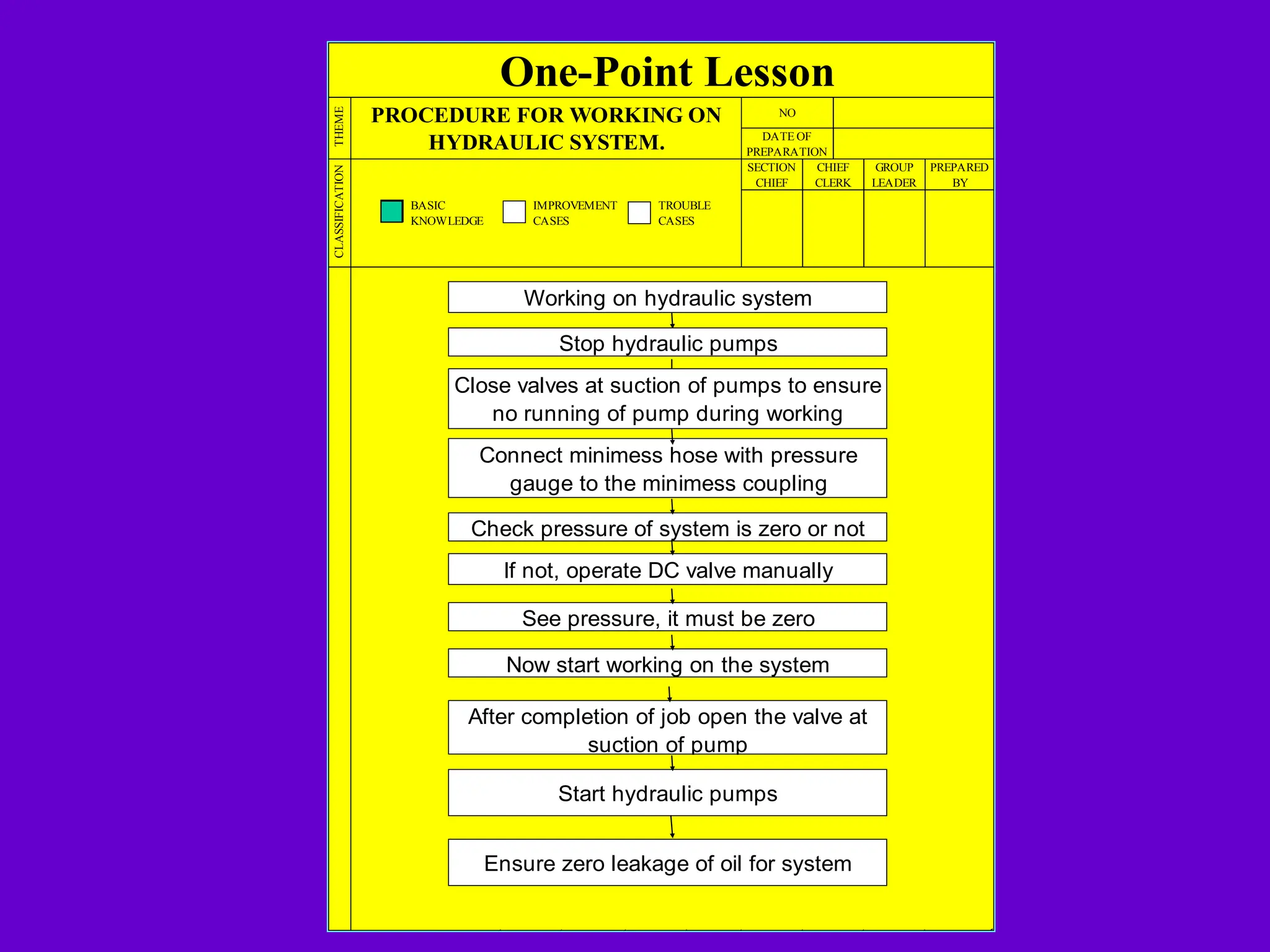

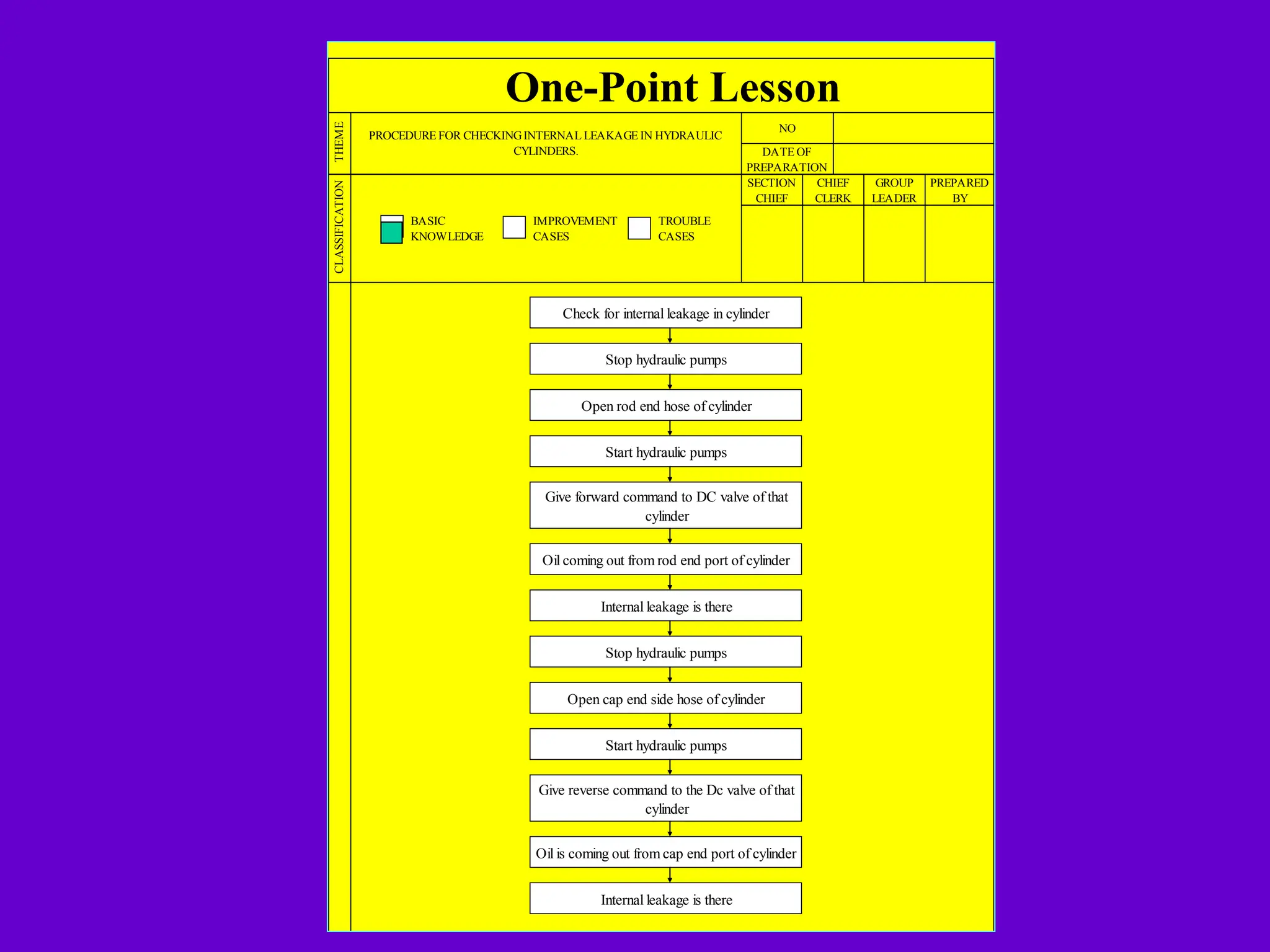

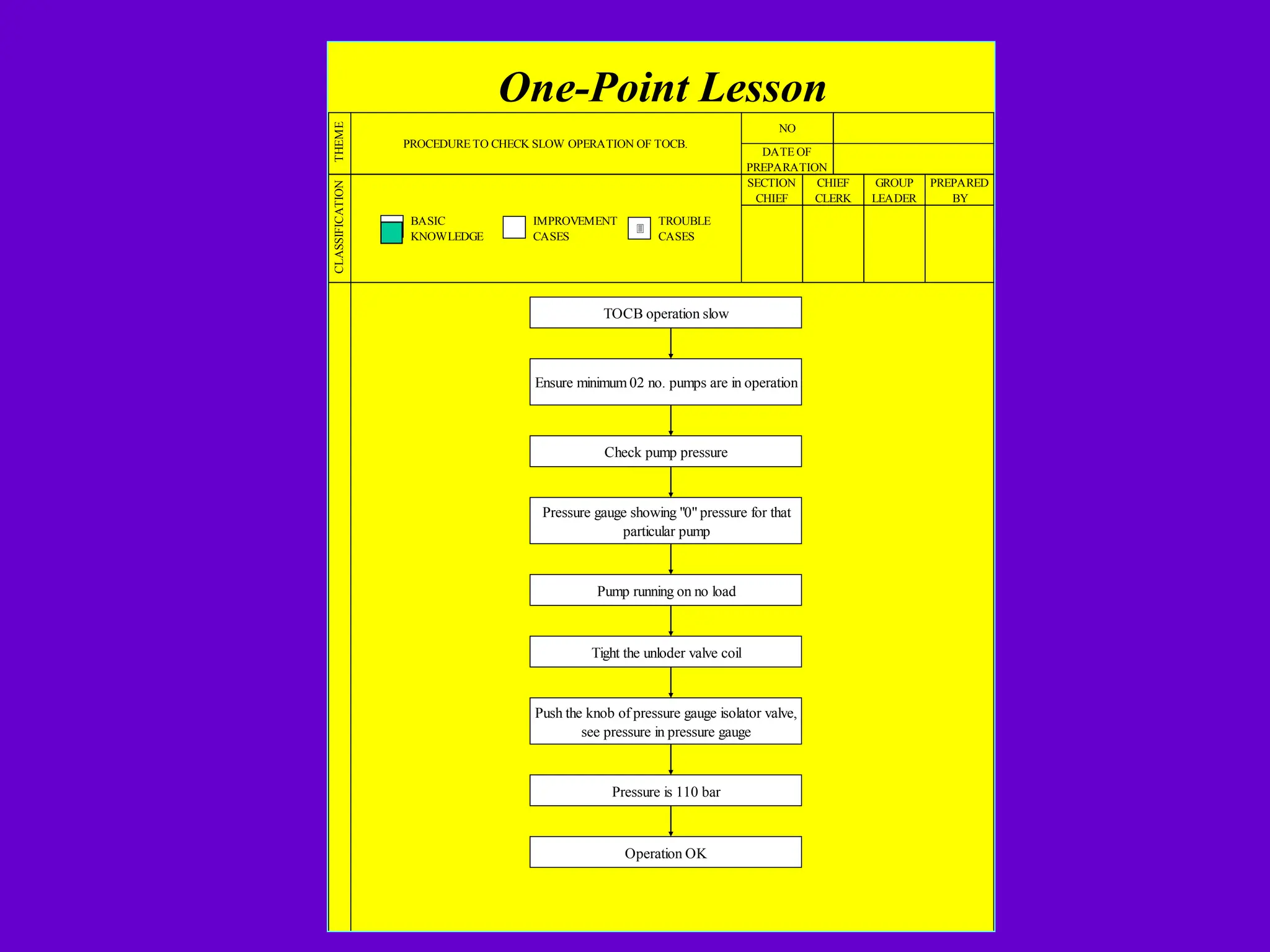

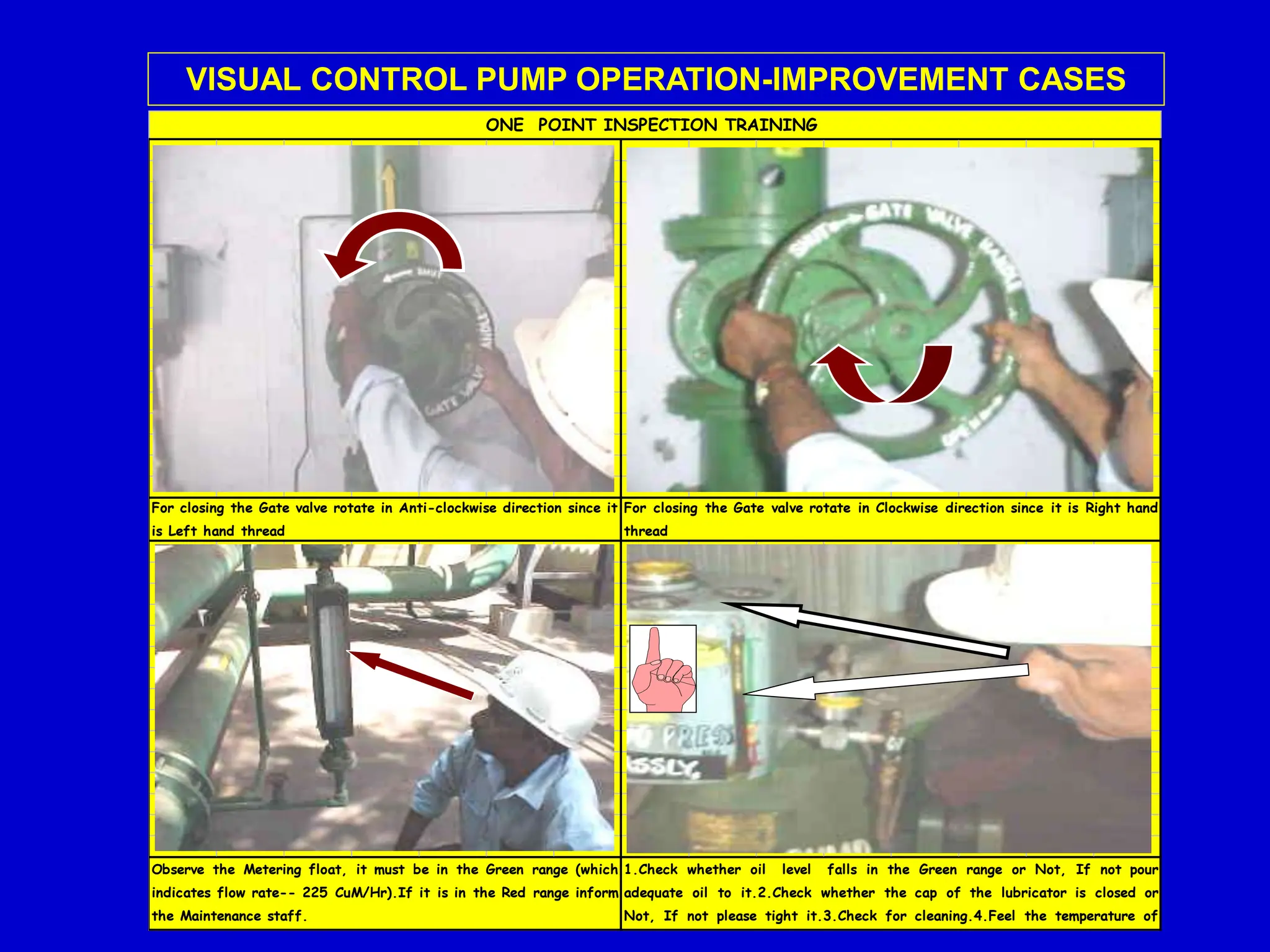

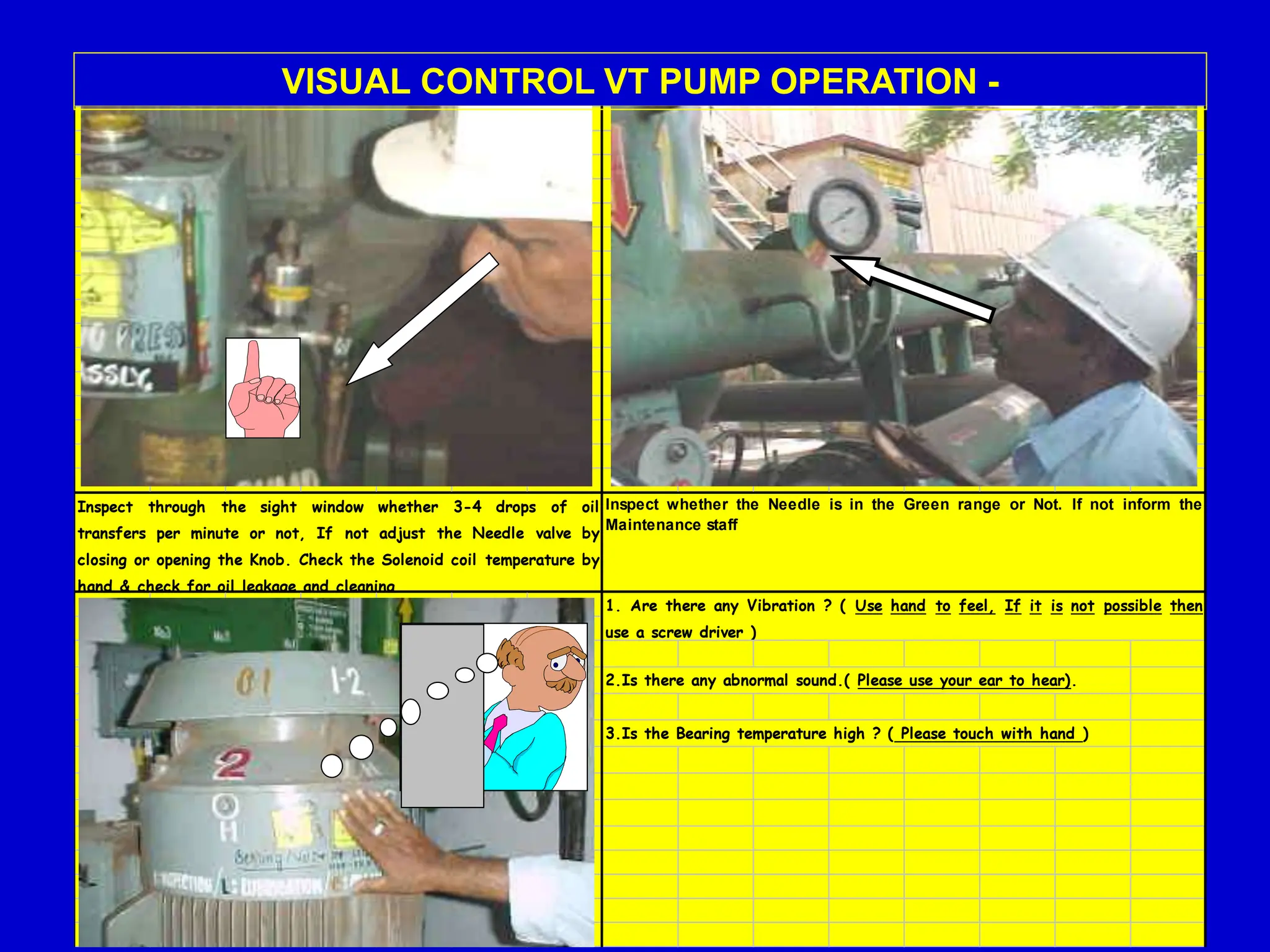

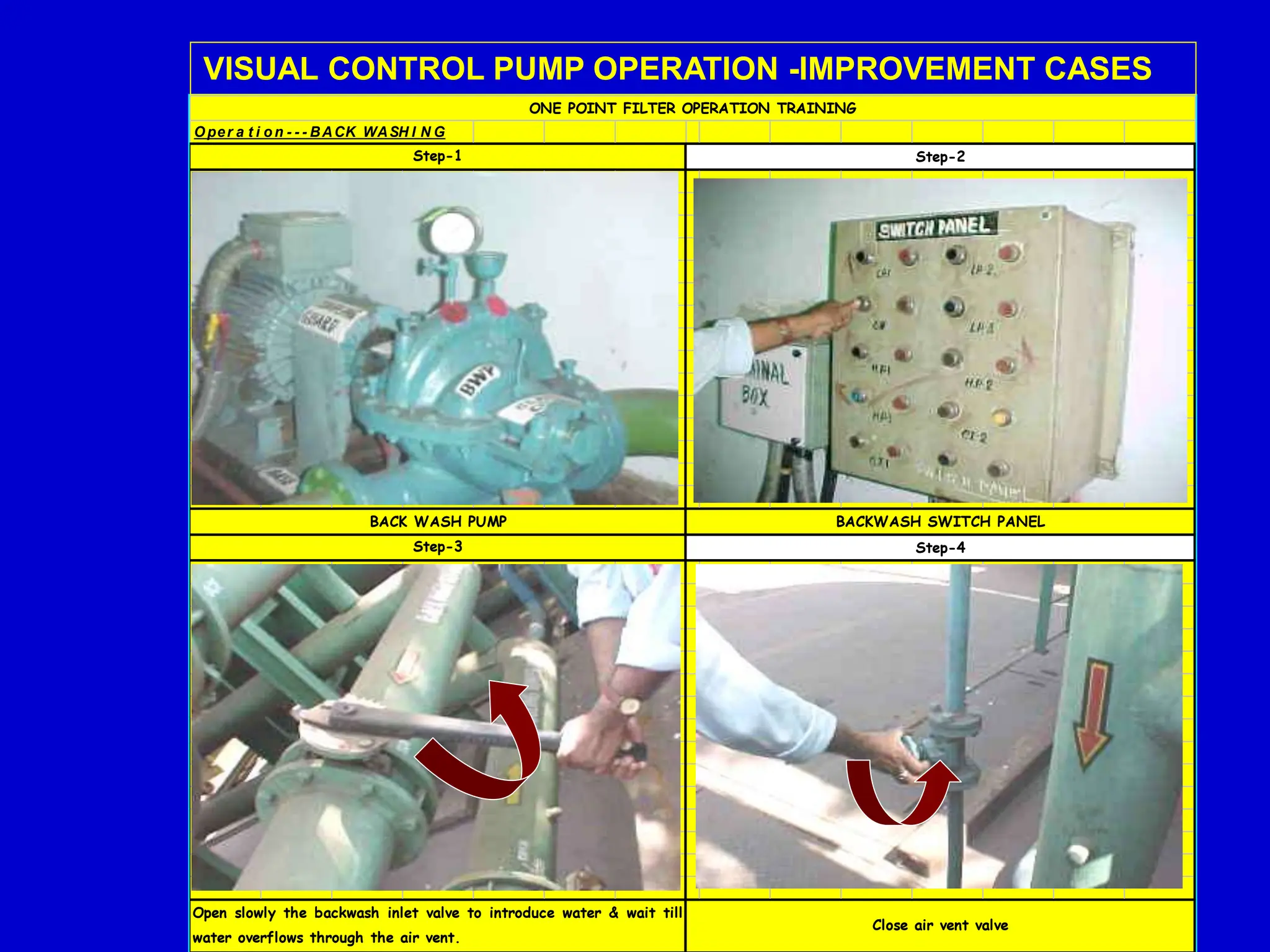

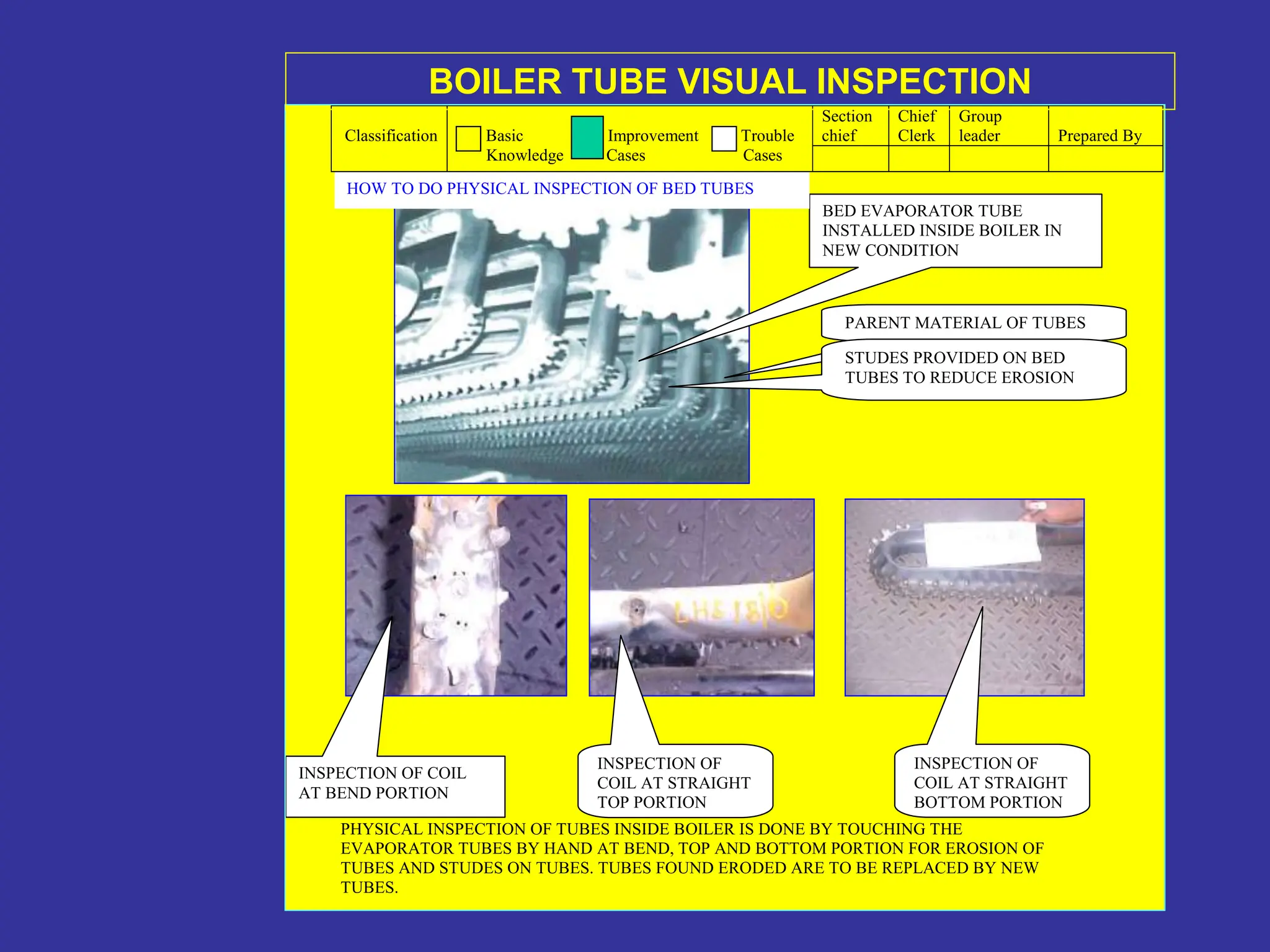

One Point Lessons are concise knowledge-sharing tools designed to enhance understanding of specific machinery components through visualization rather than extensive text. They aim to improve skills, facilitate basic knowledge, and address trouble cases related to various machine parts, such as bearings, couplings, and hydraulic systems. The document contains detailed procedures and insights on maintenance practices, operational procedures, and troubleshooting techniques for various industrial equipment.