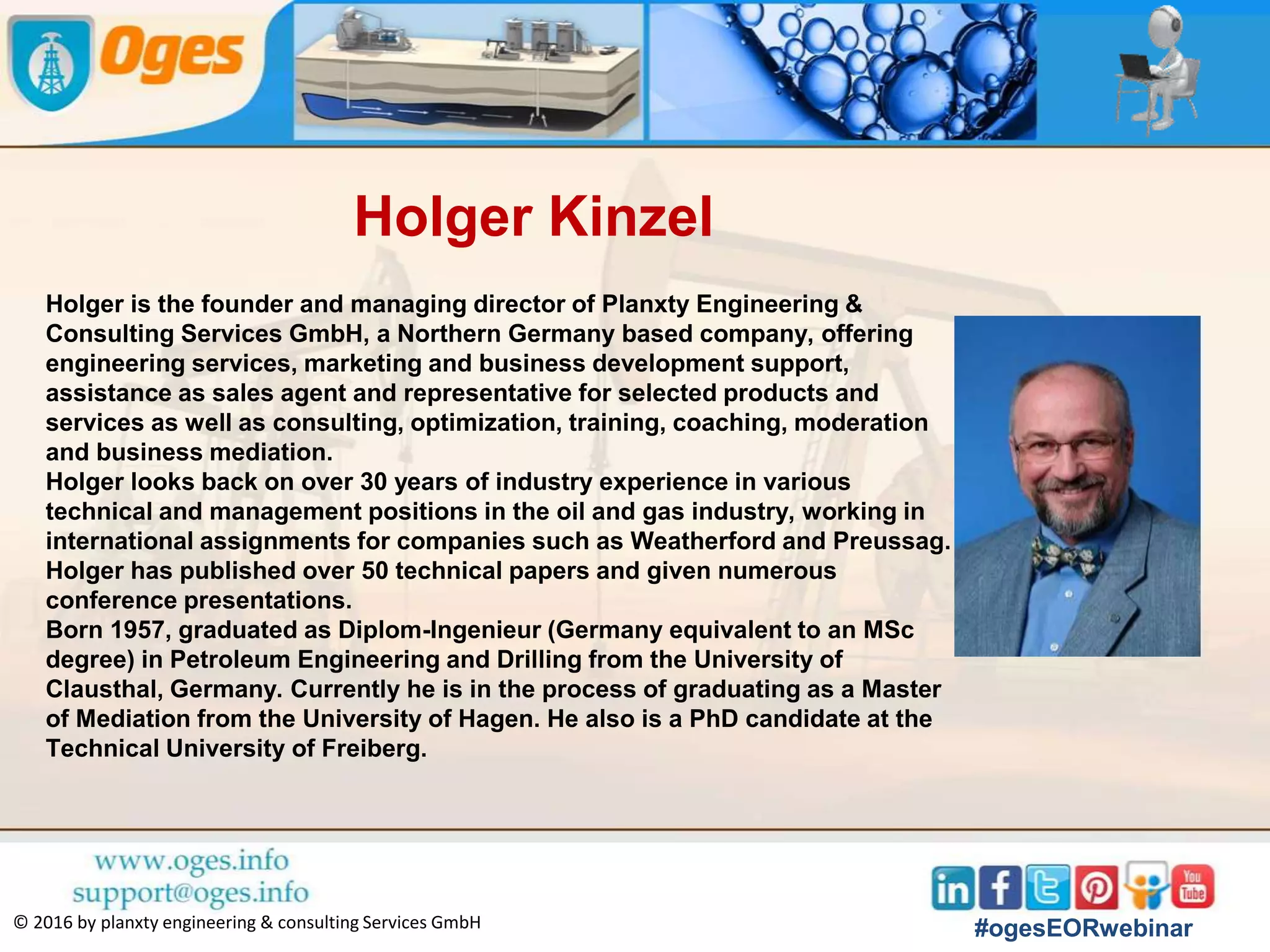

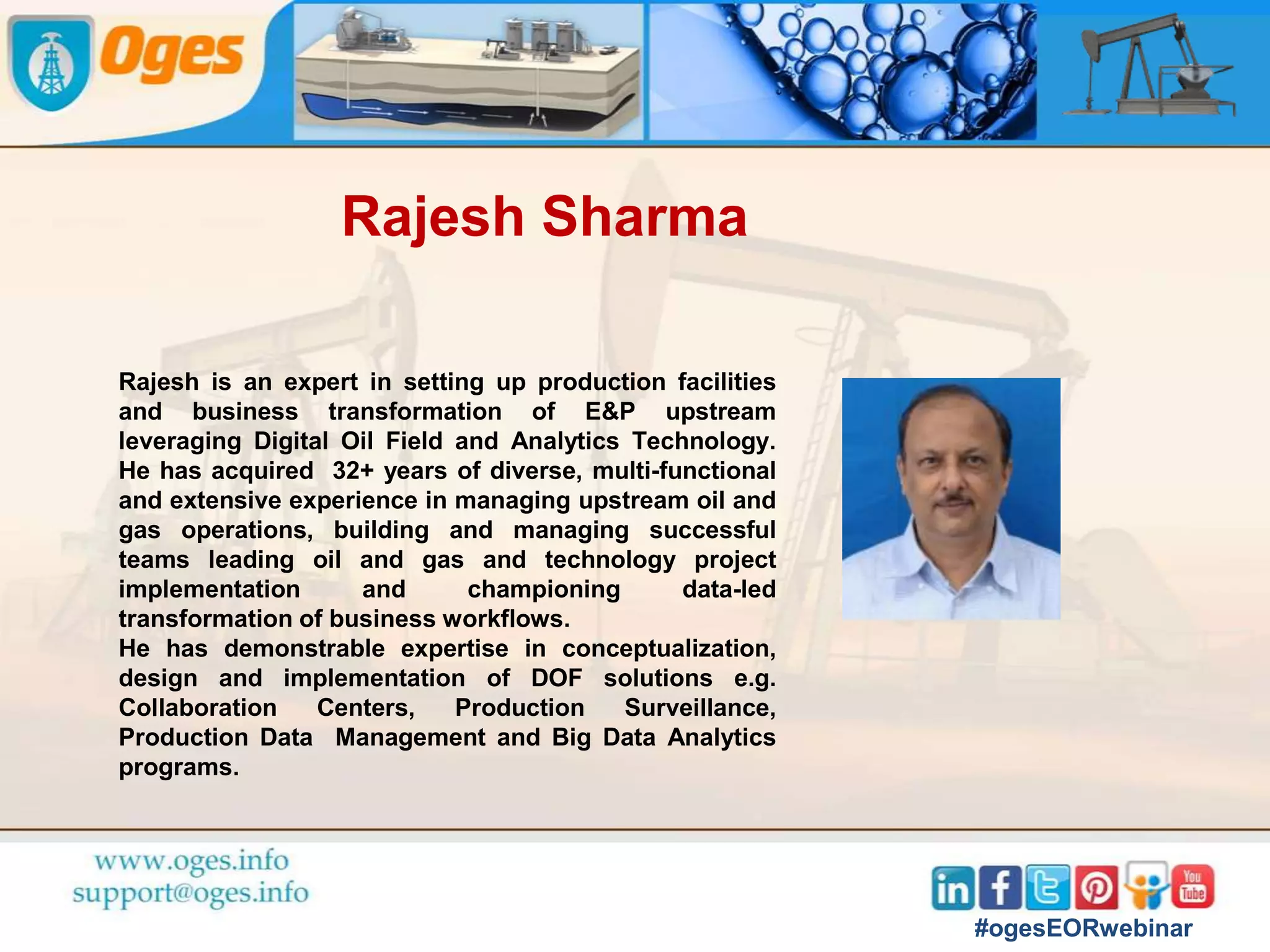

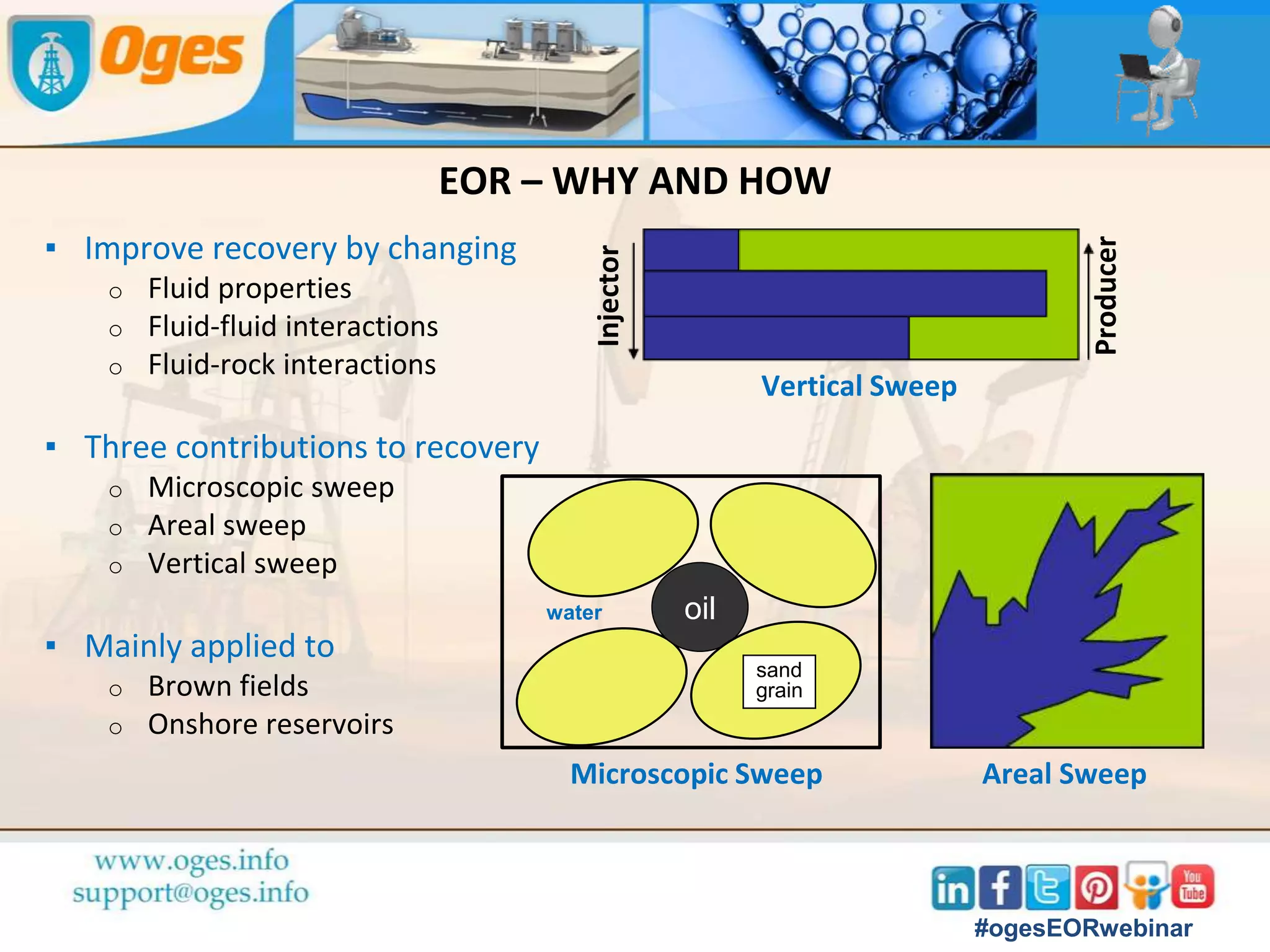

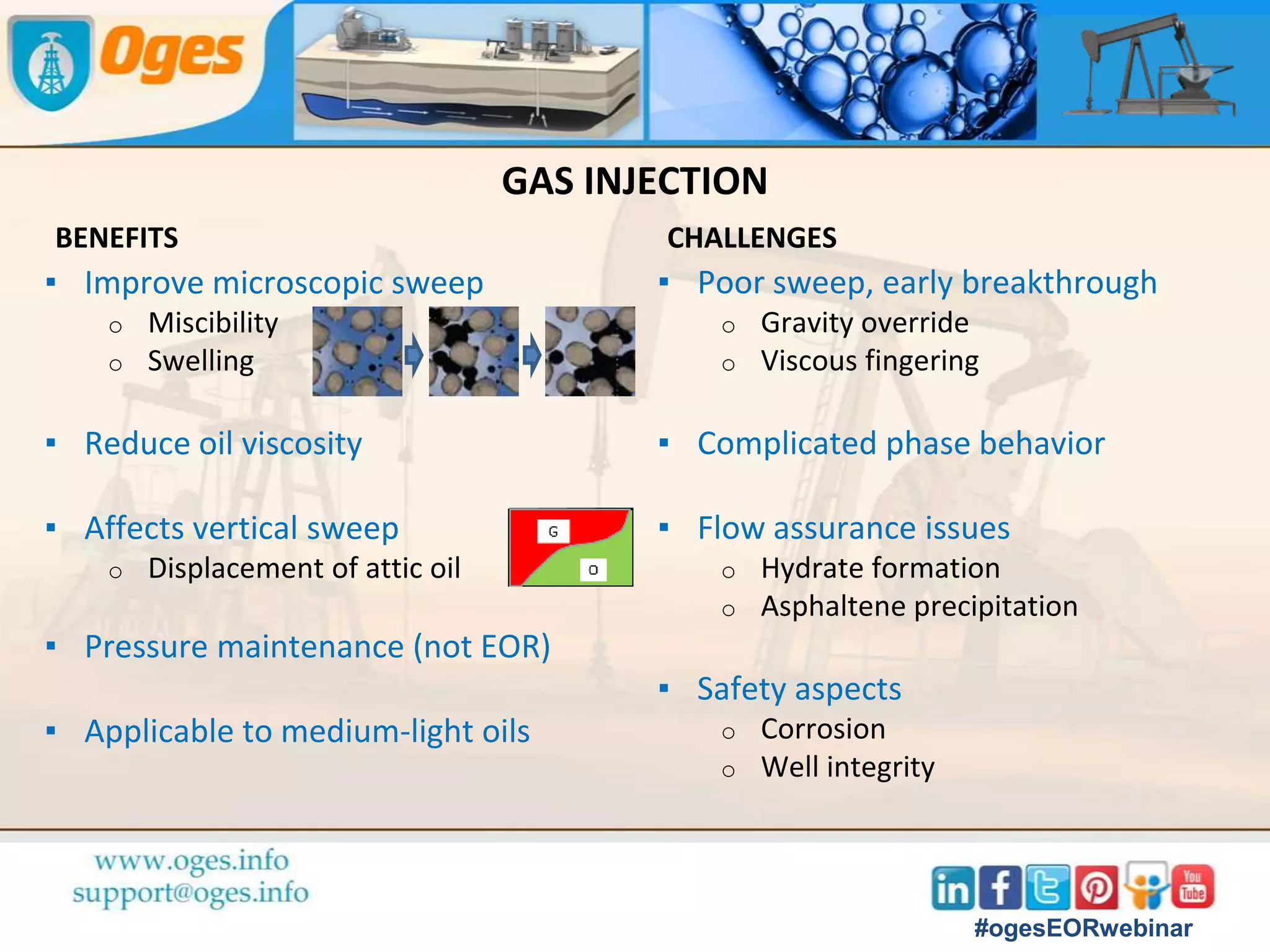

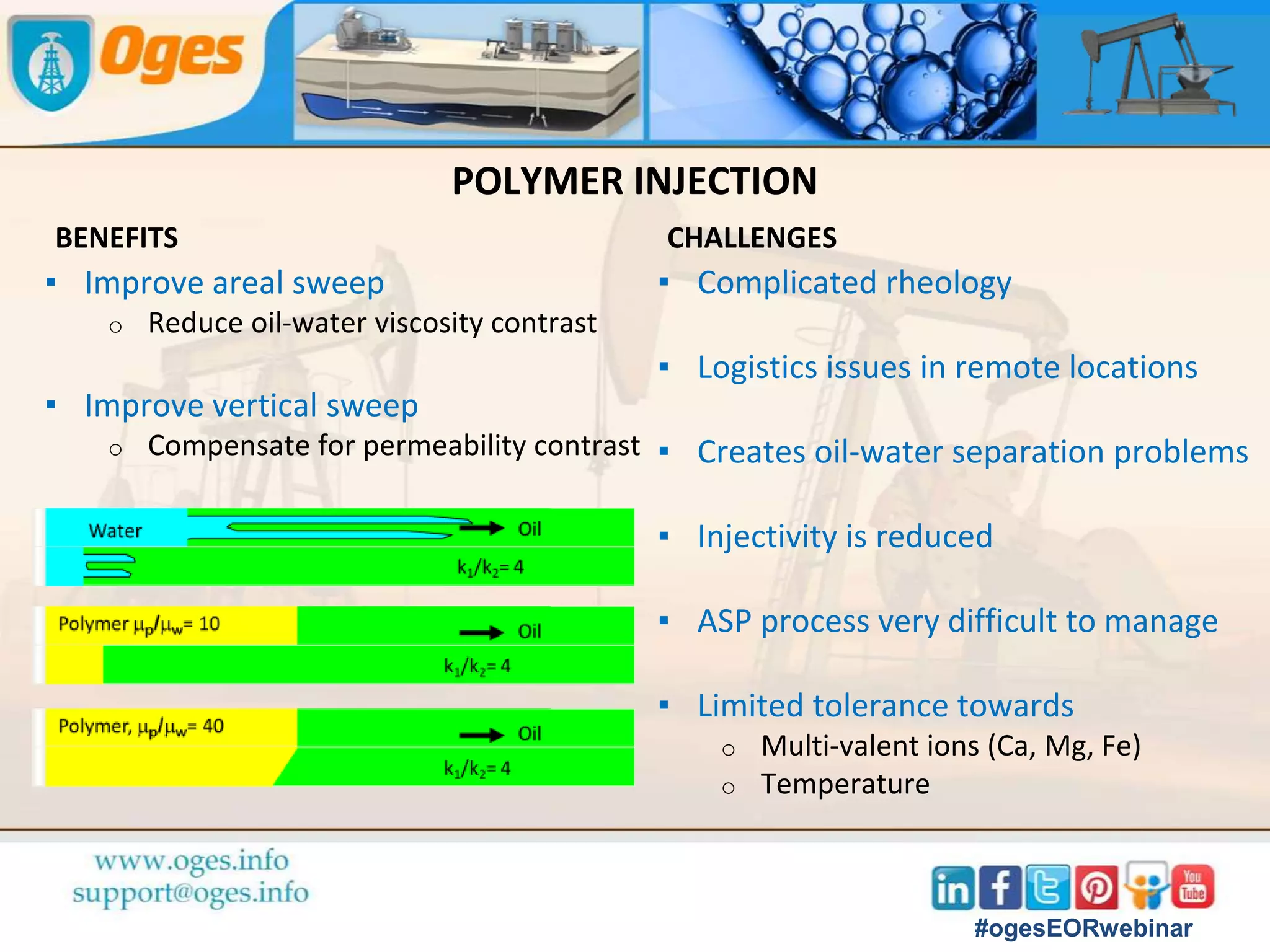

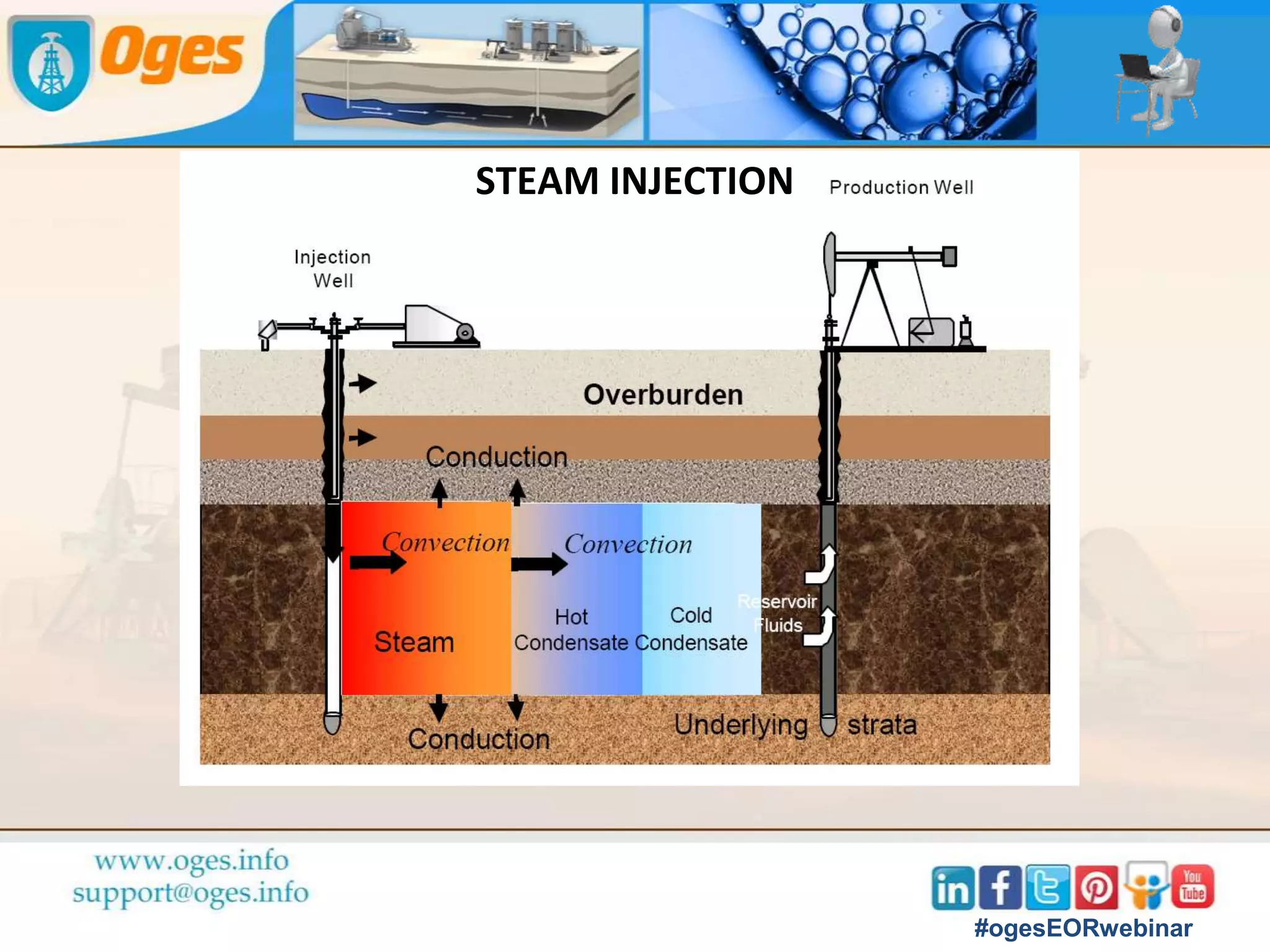

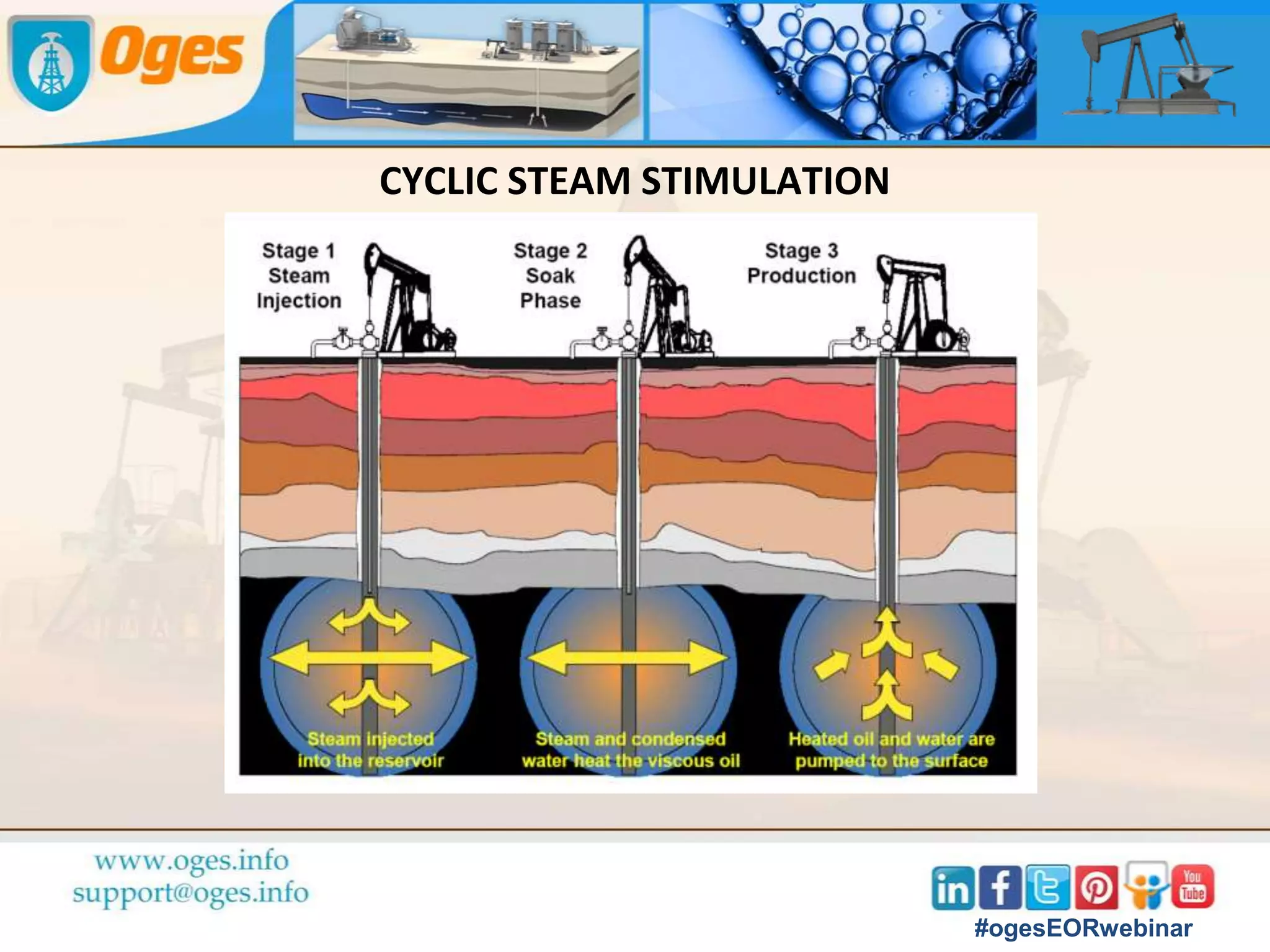

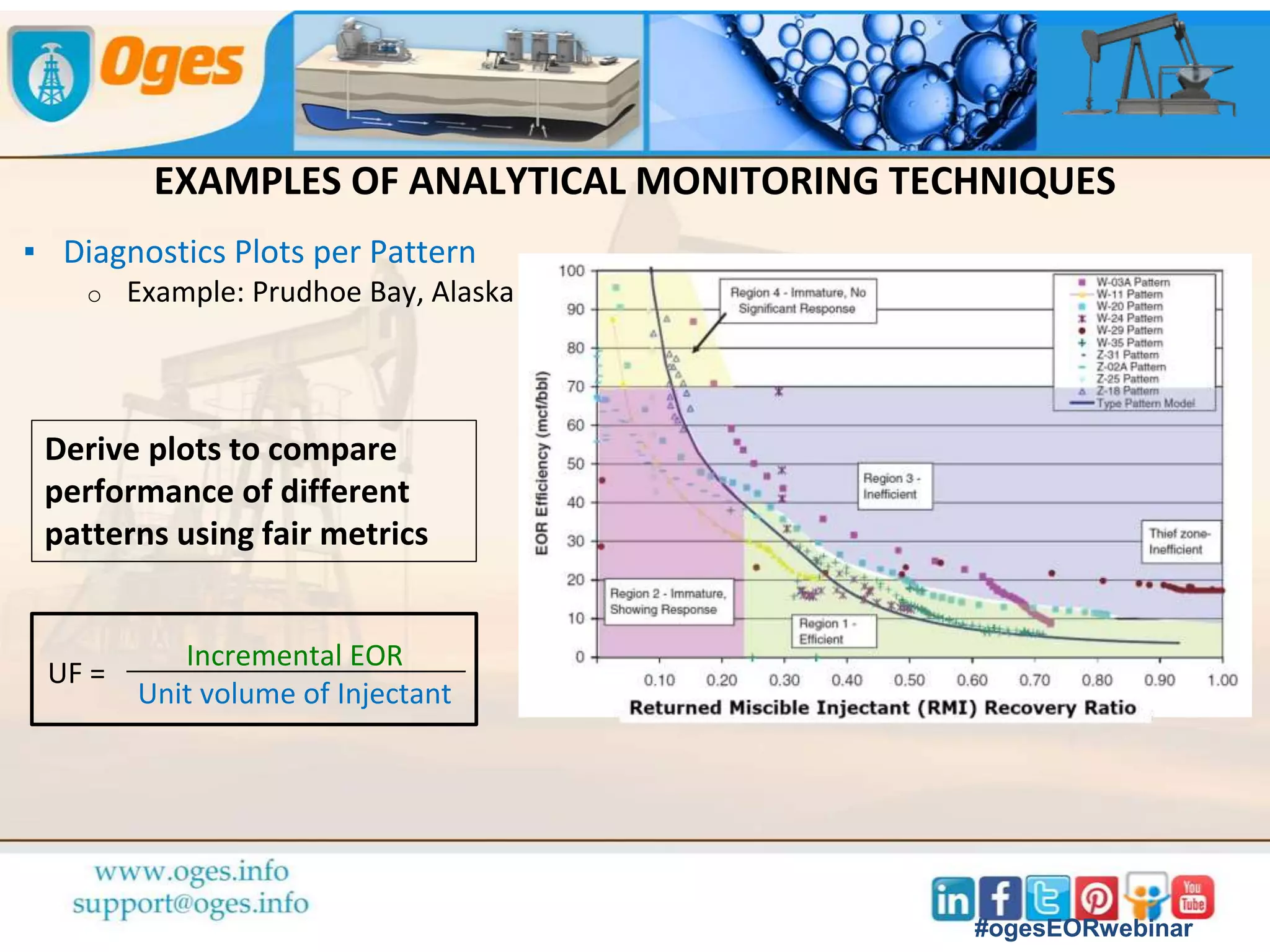

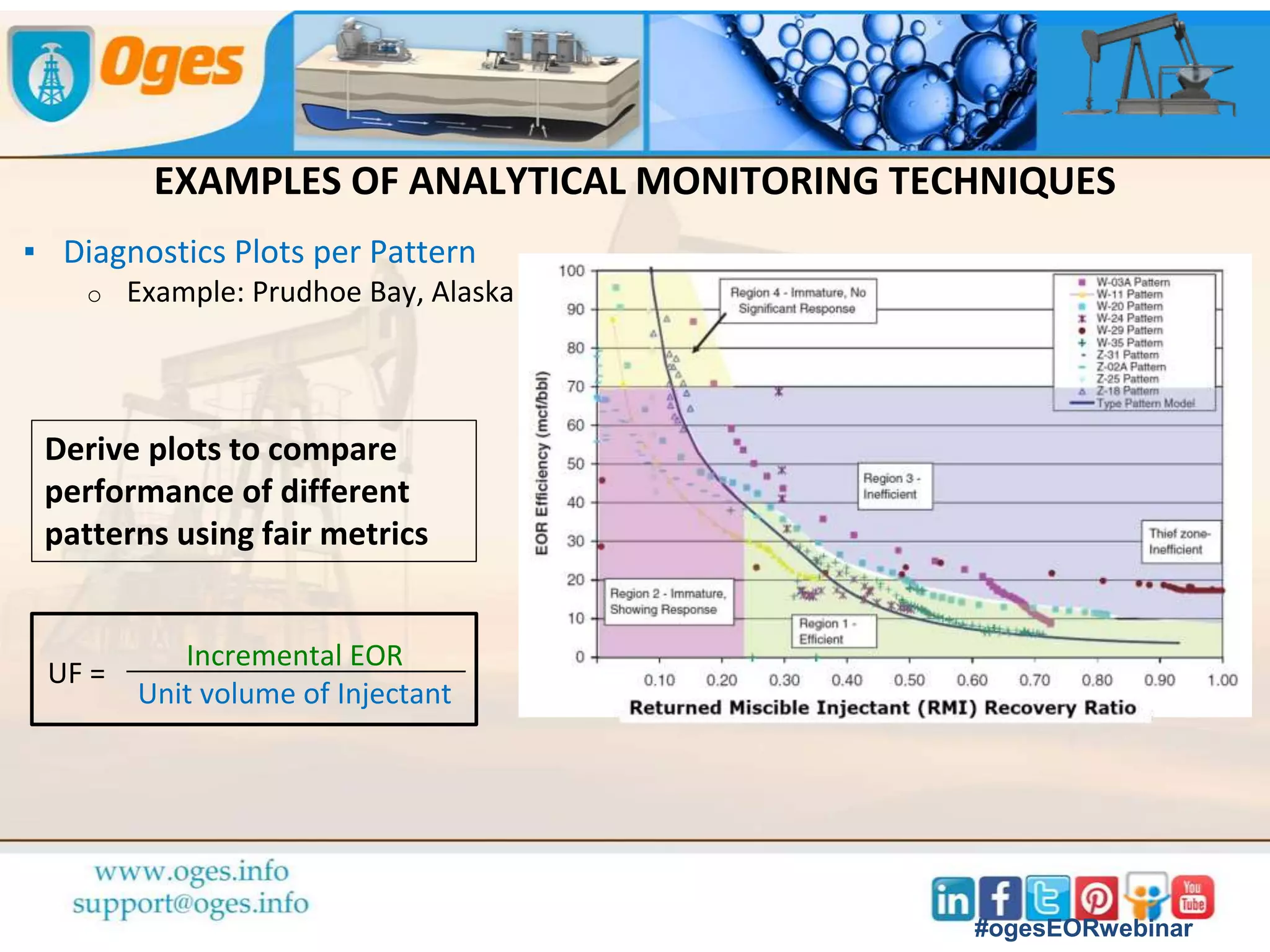

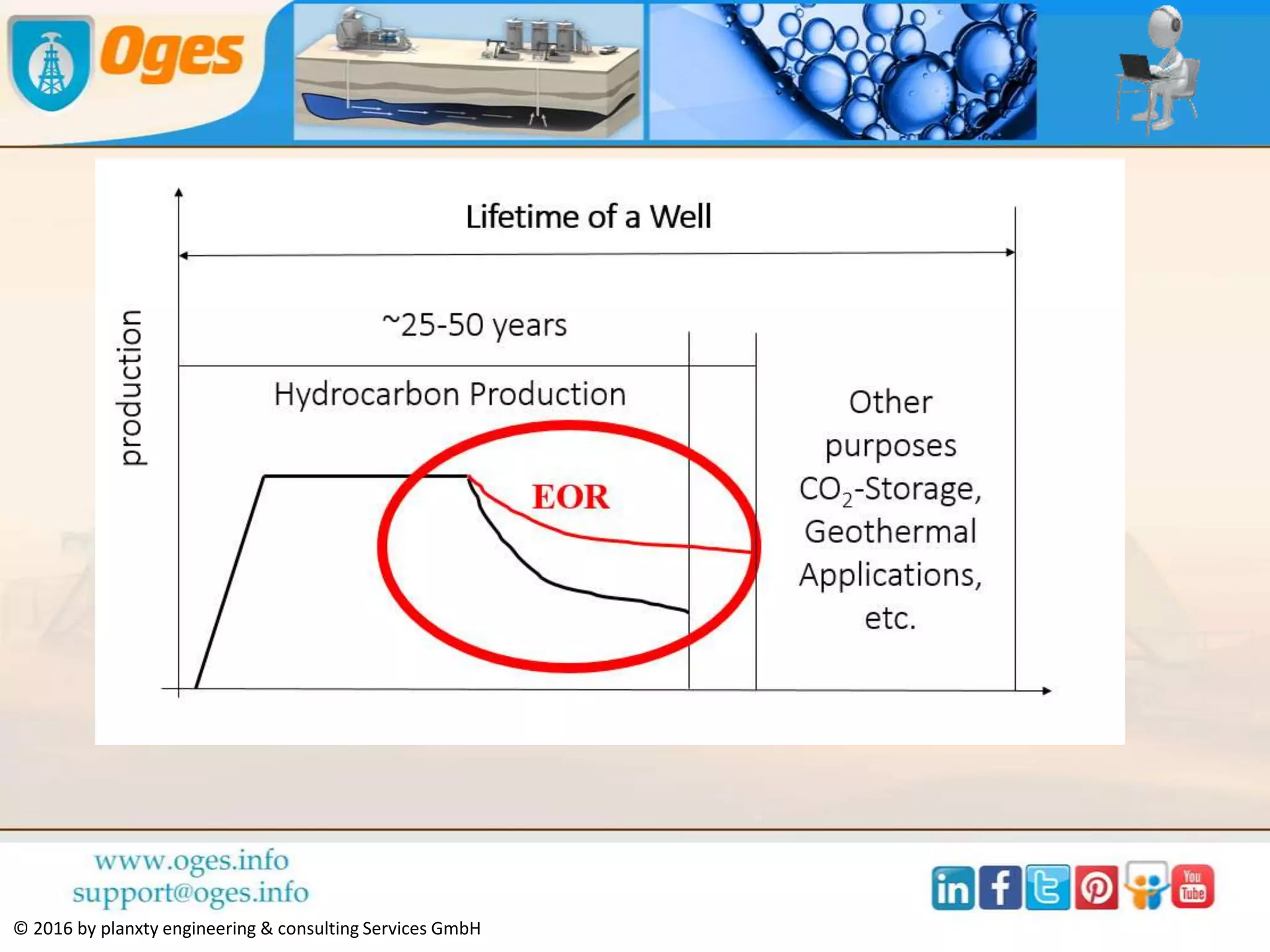

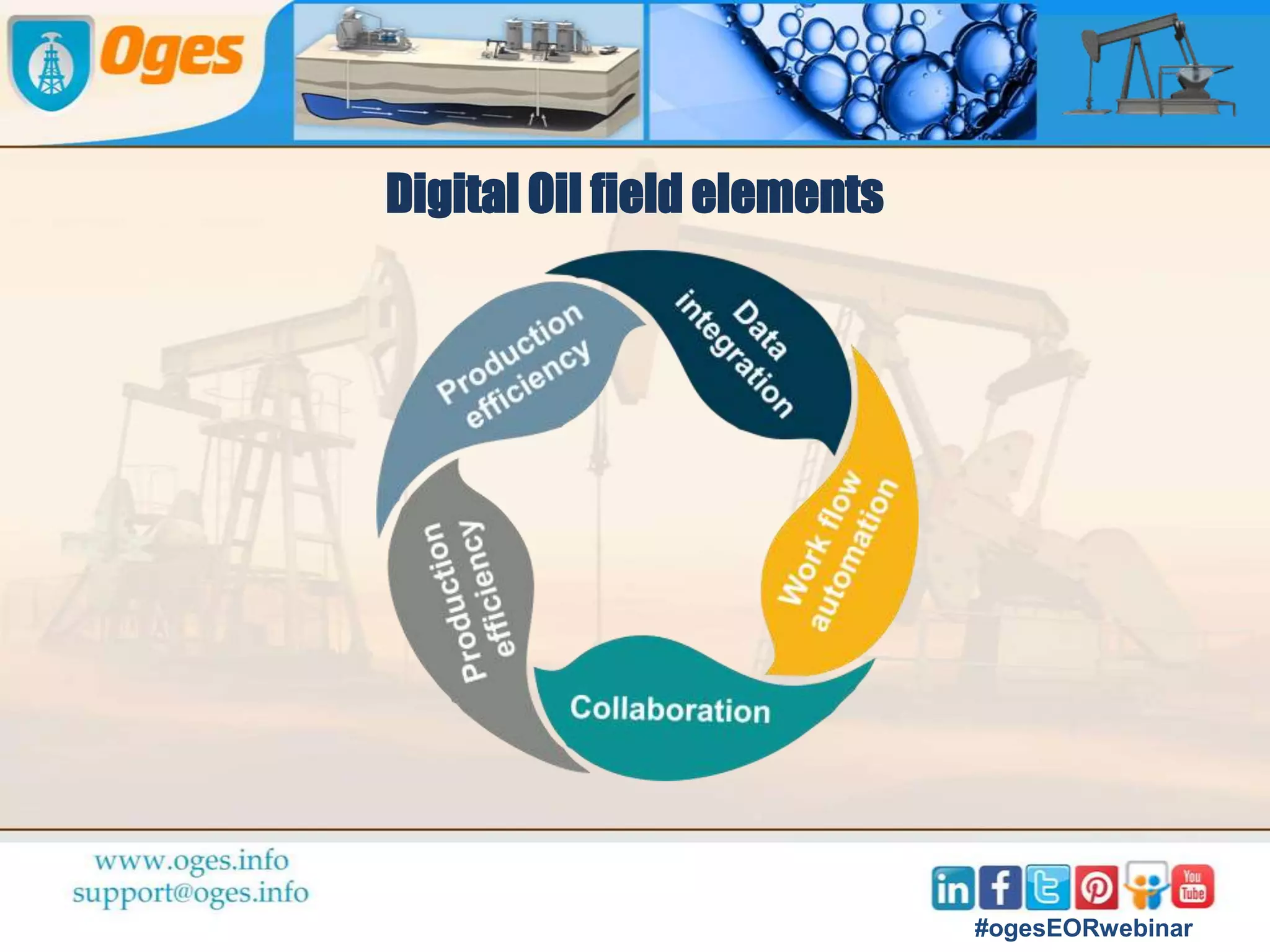

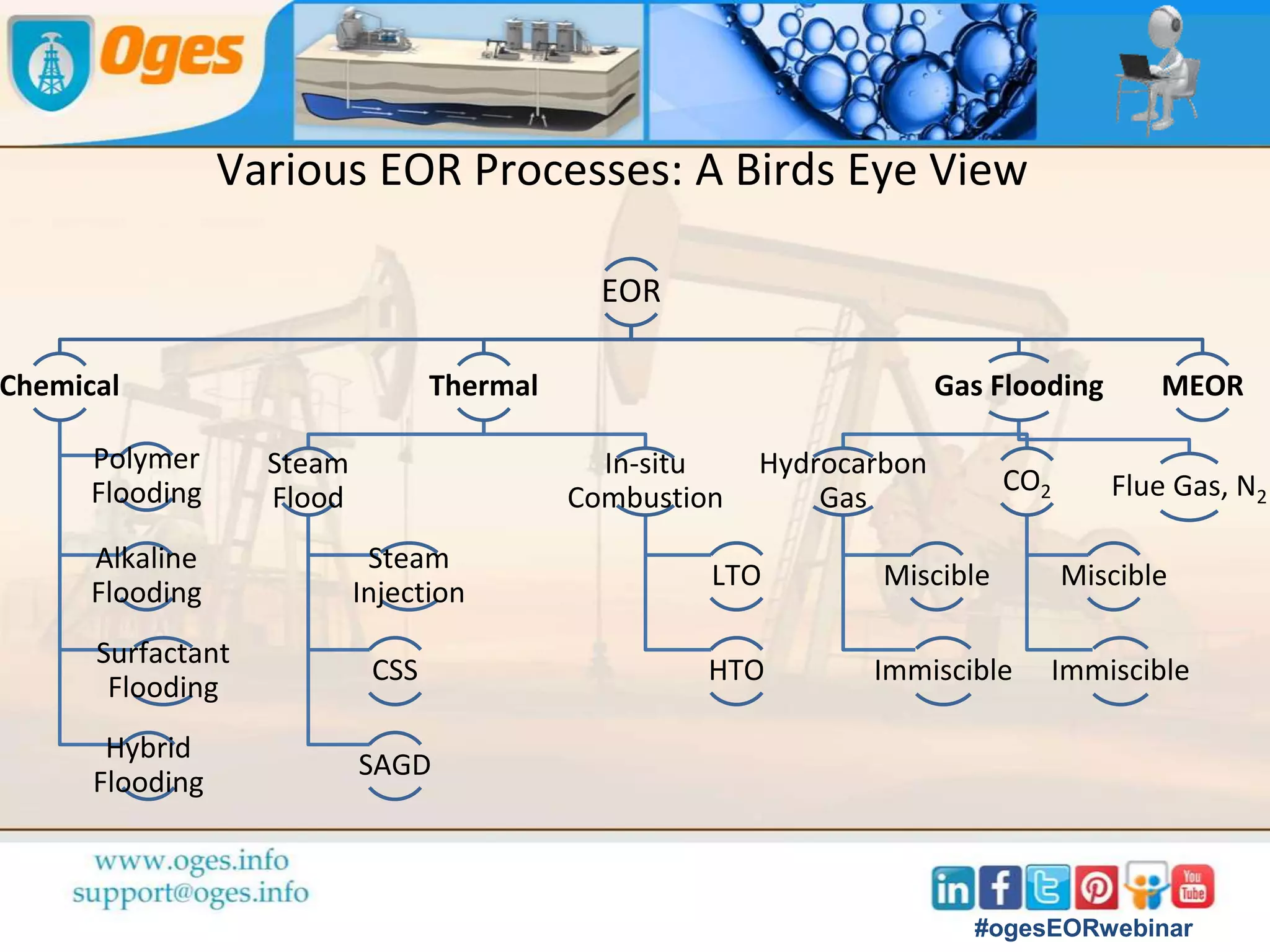

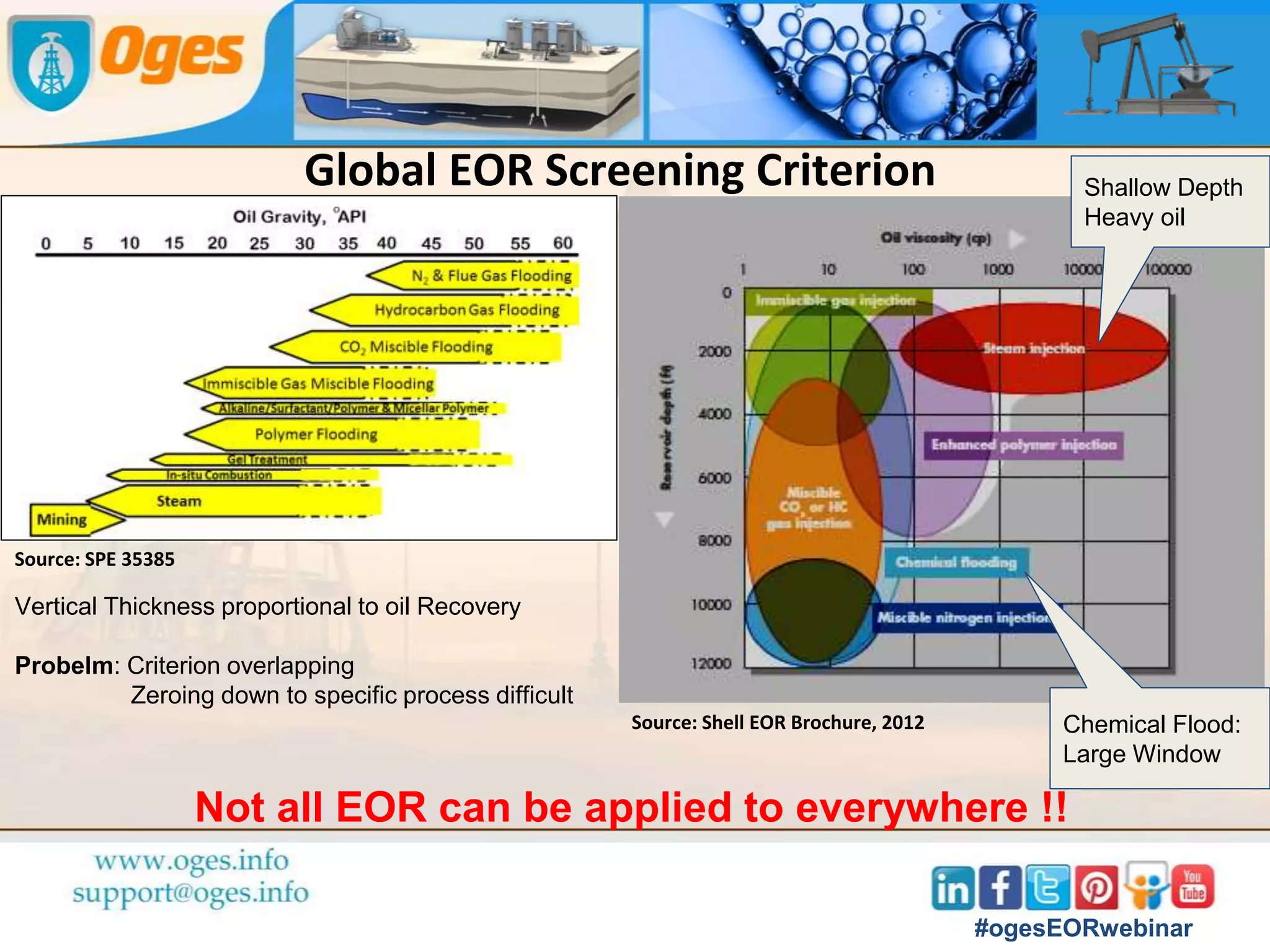

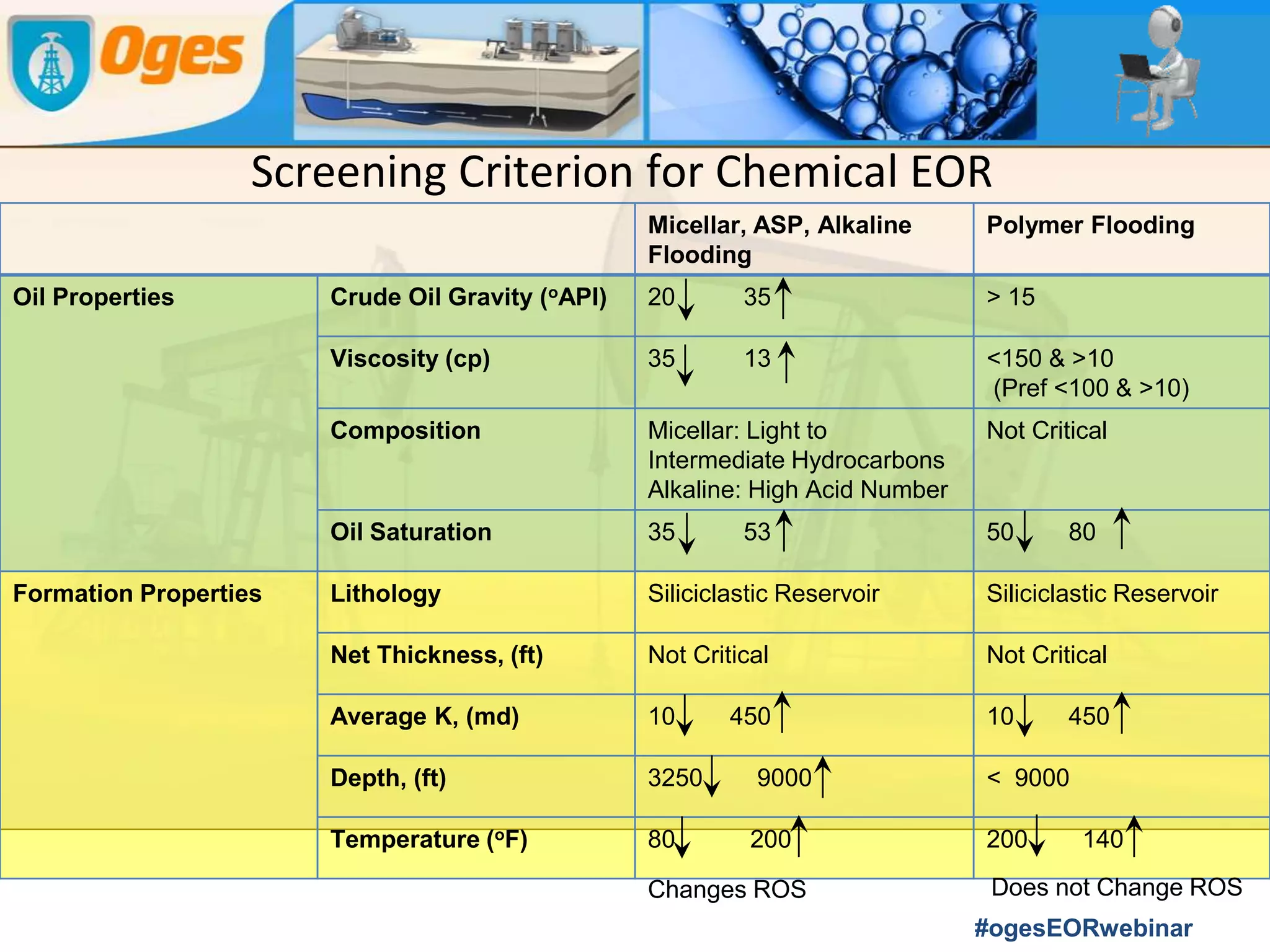

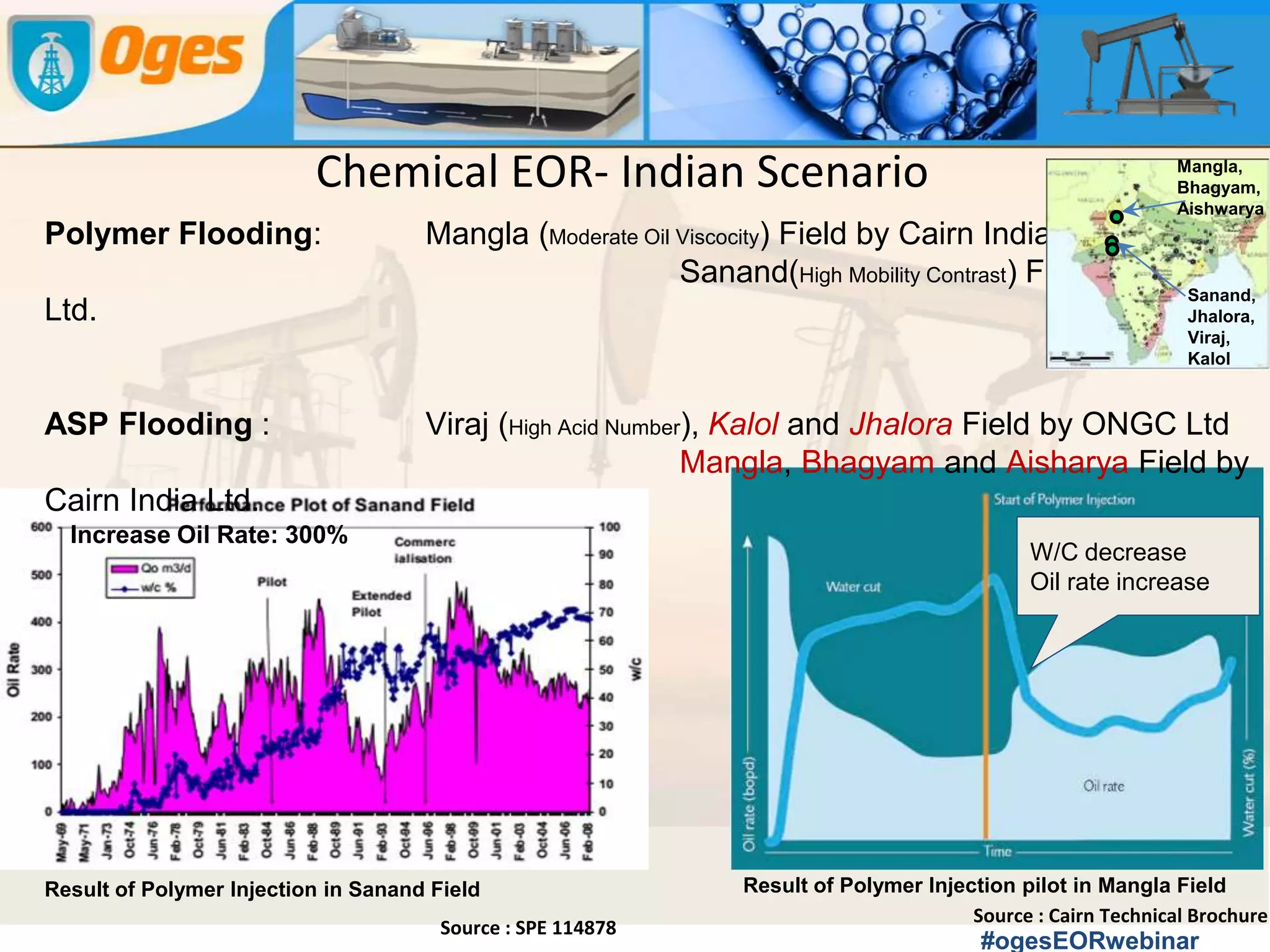

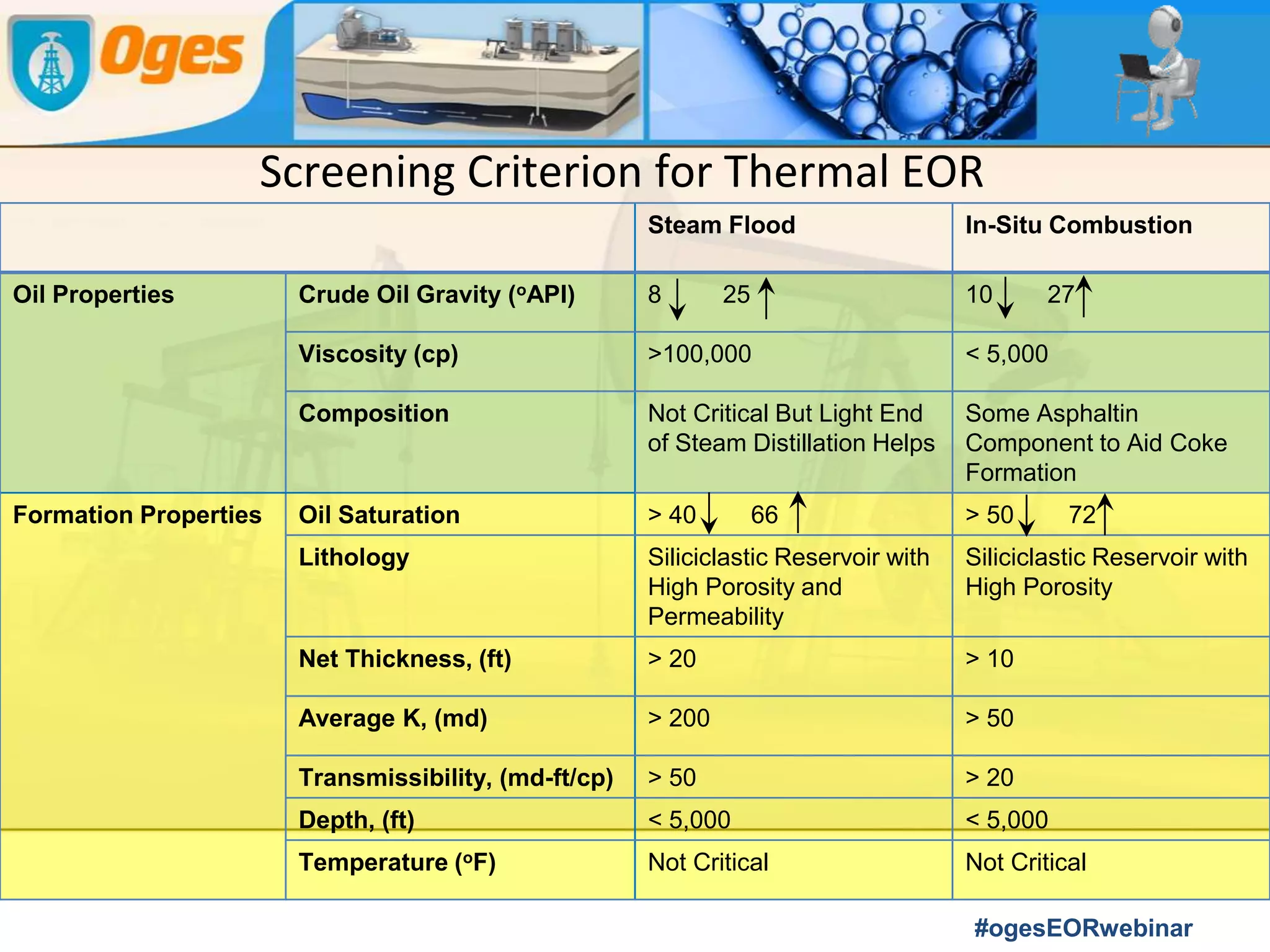

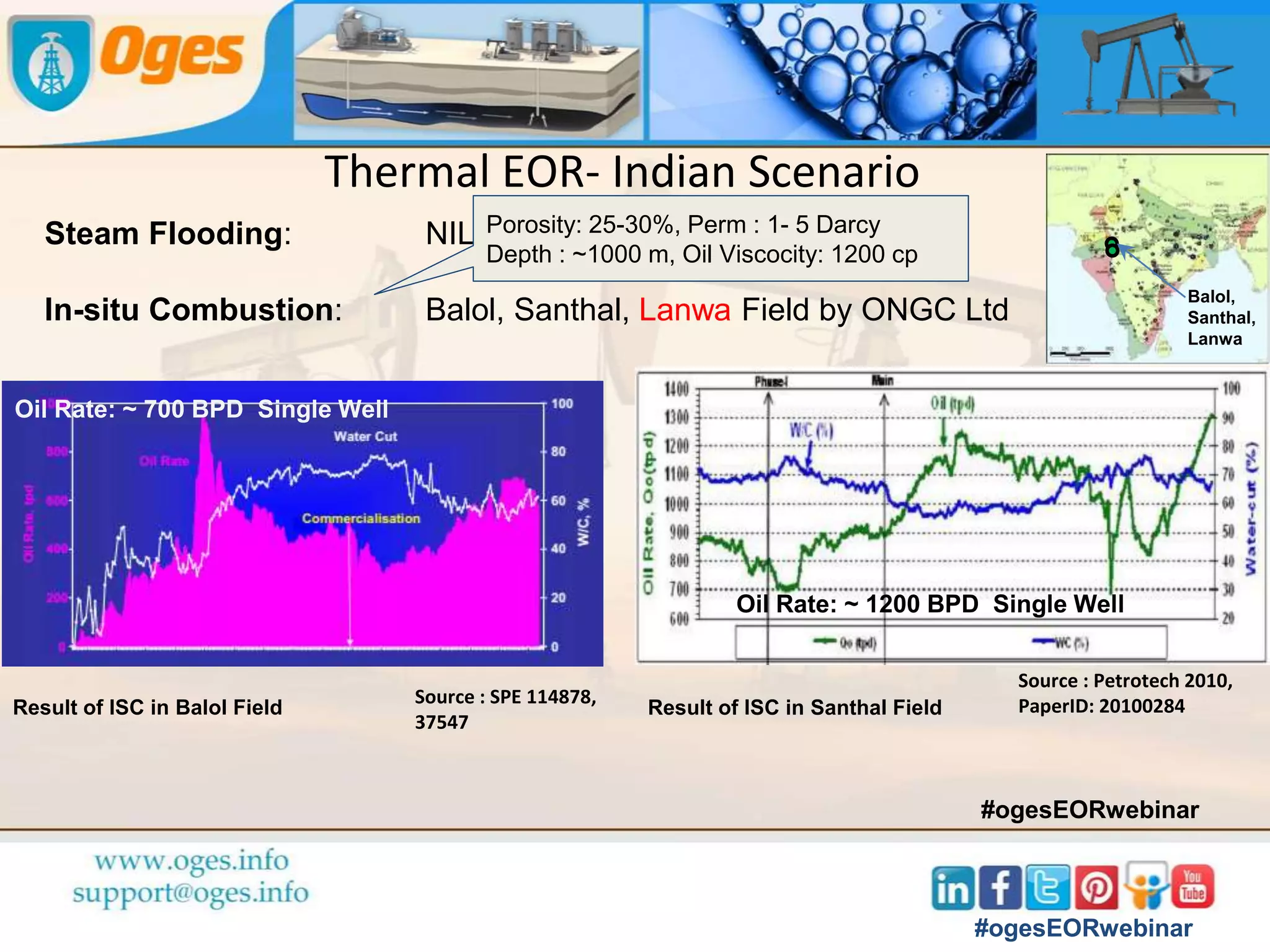

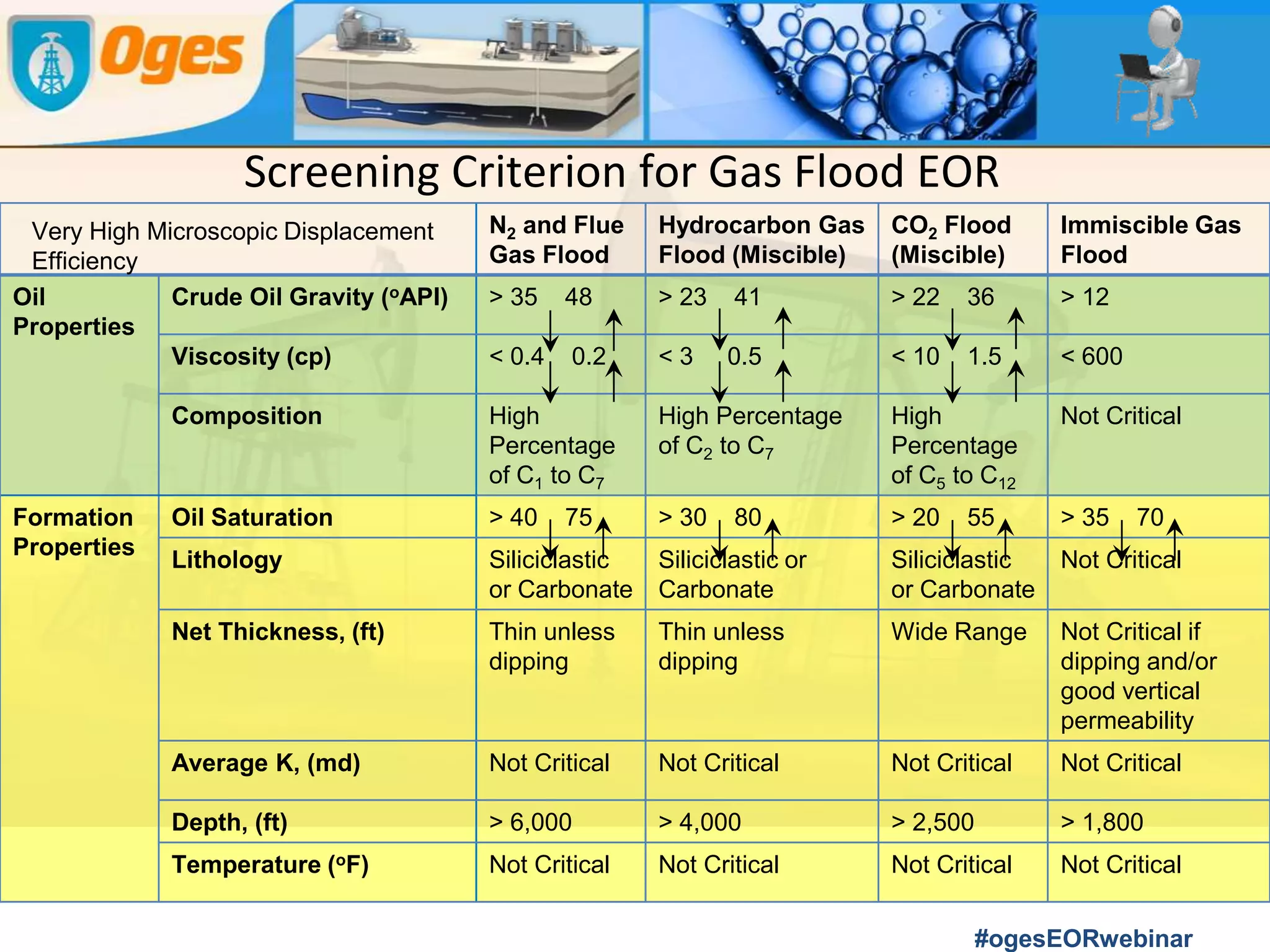

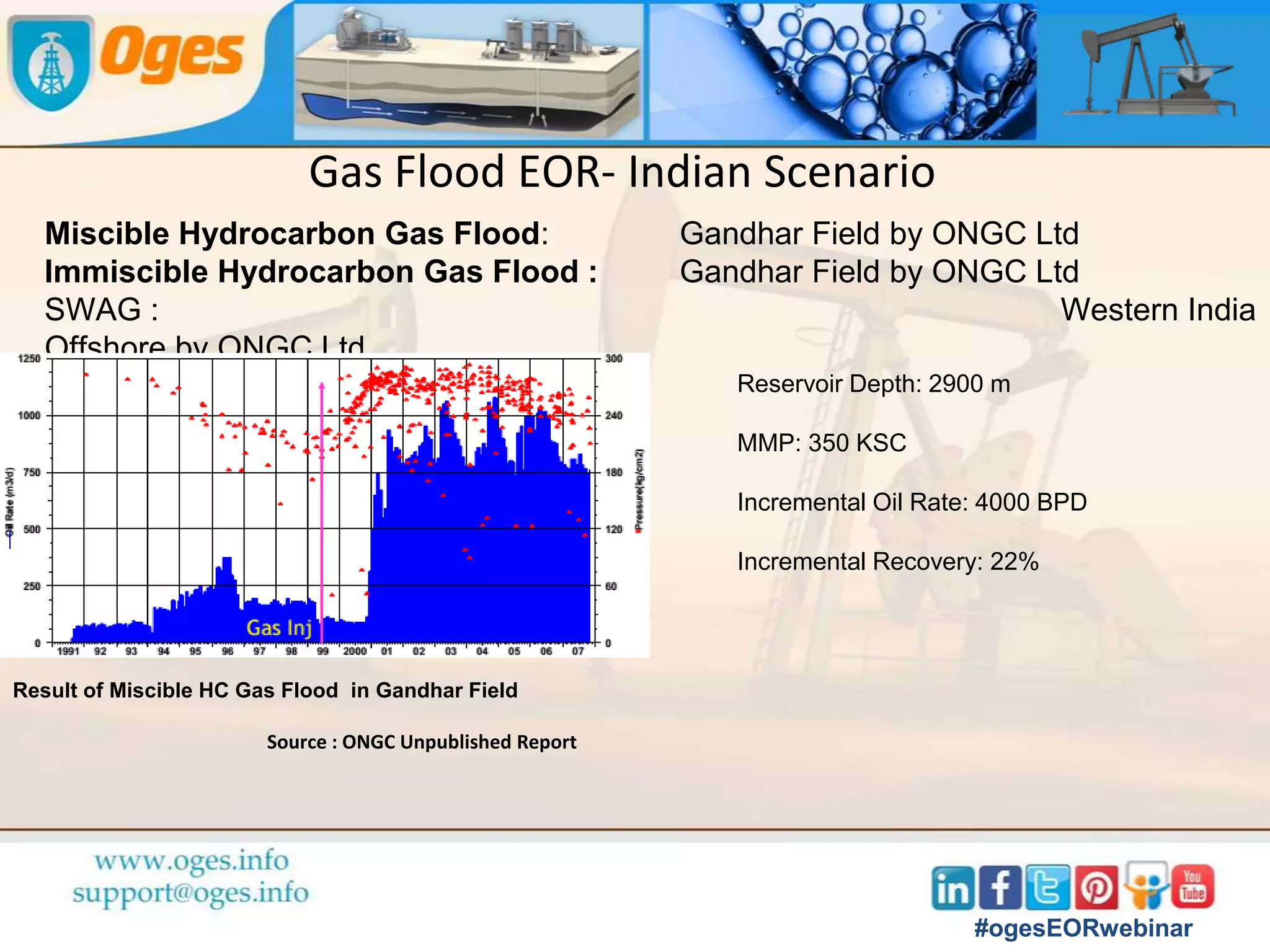

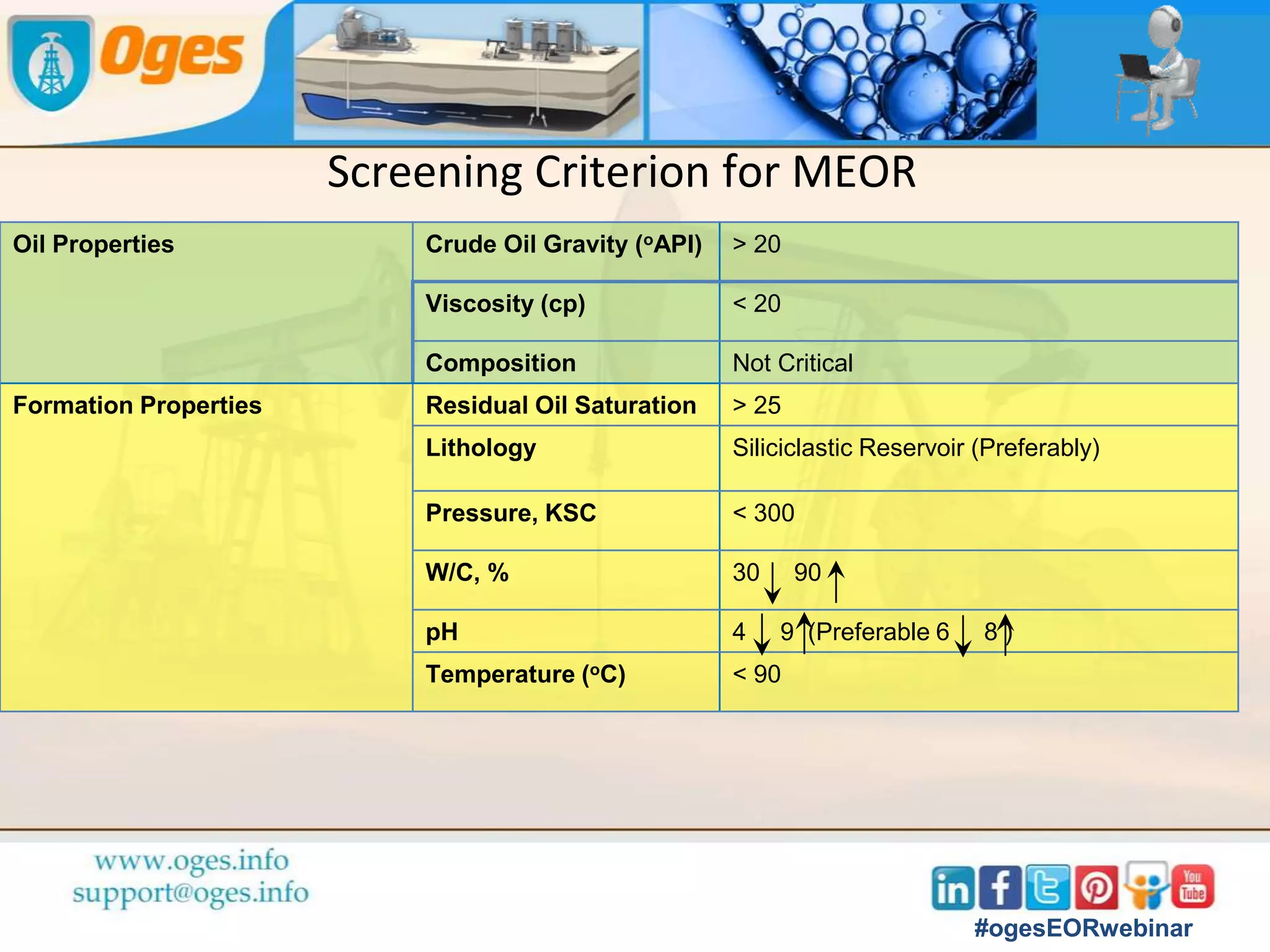

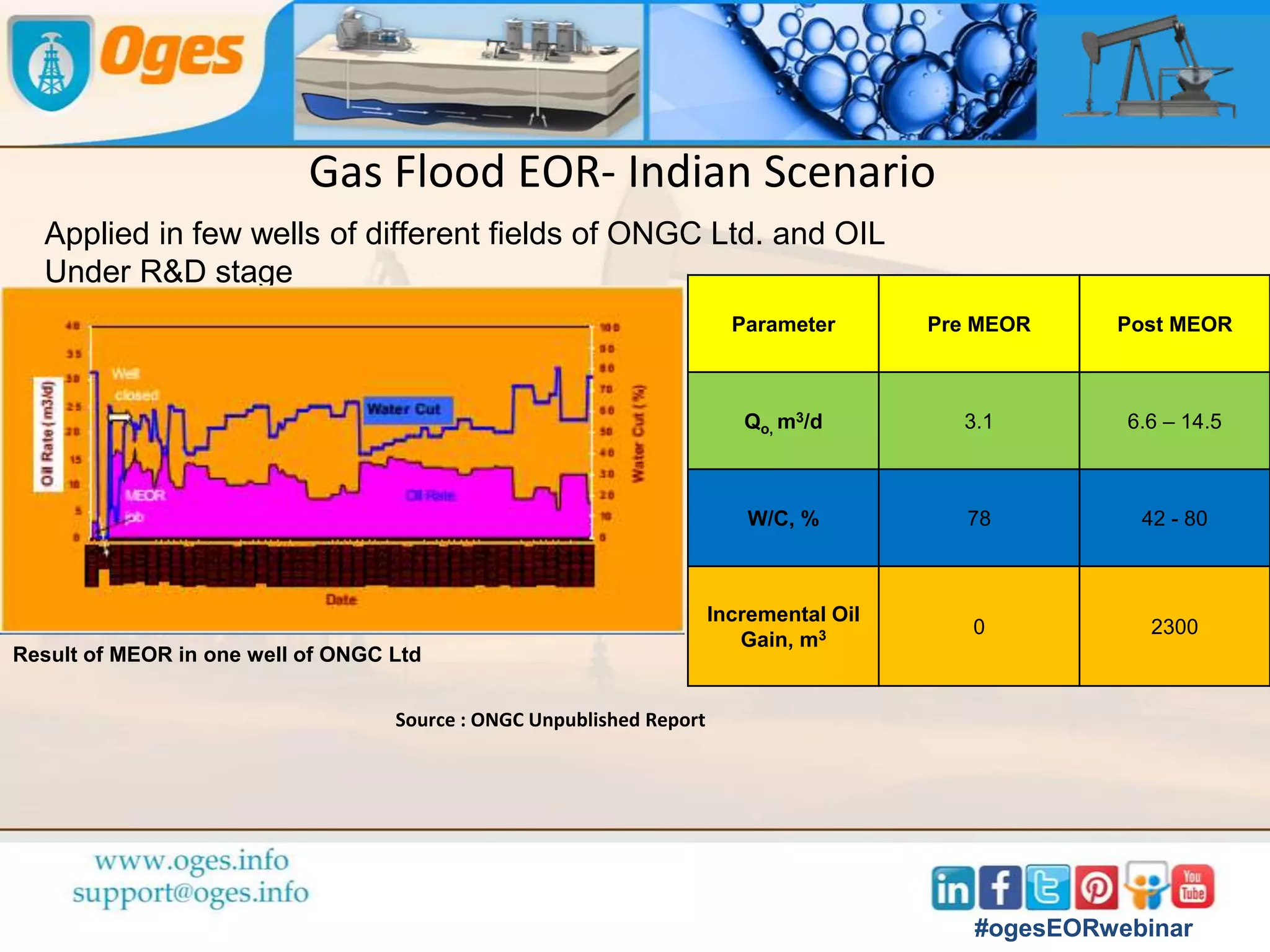

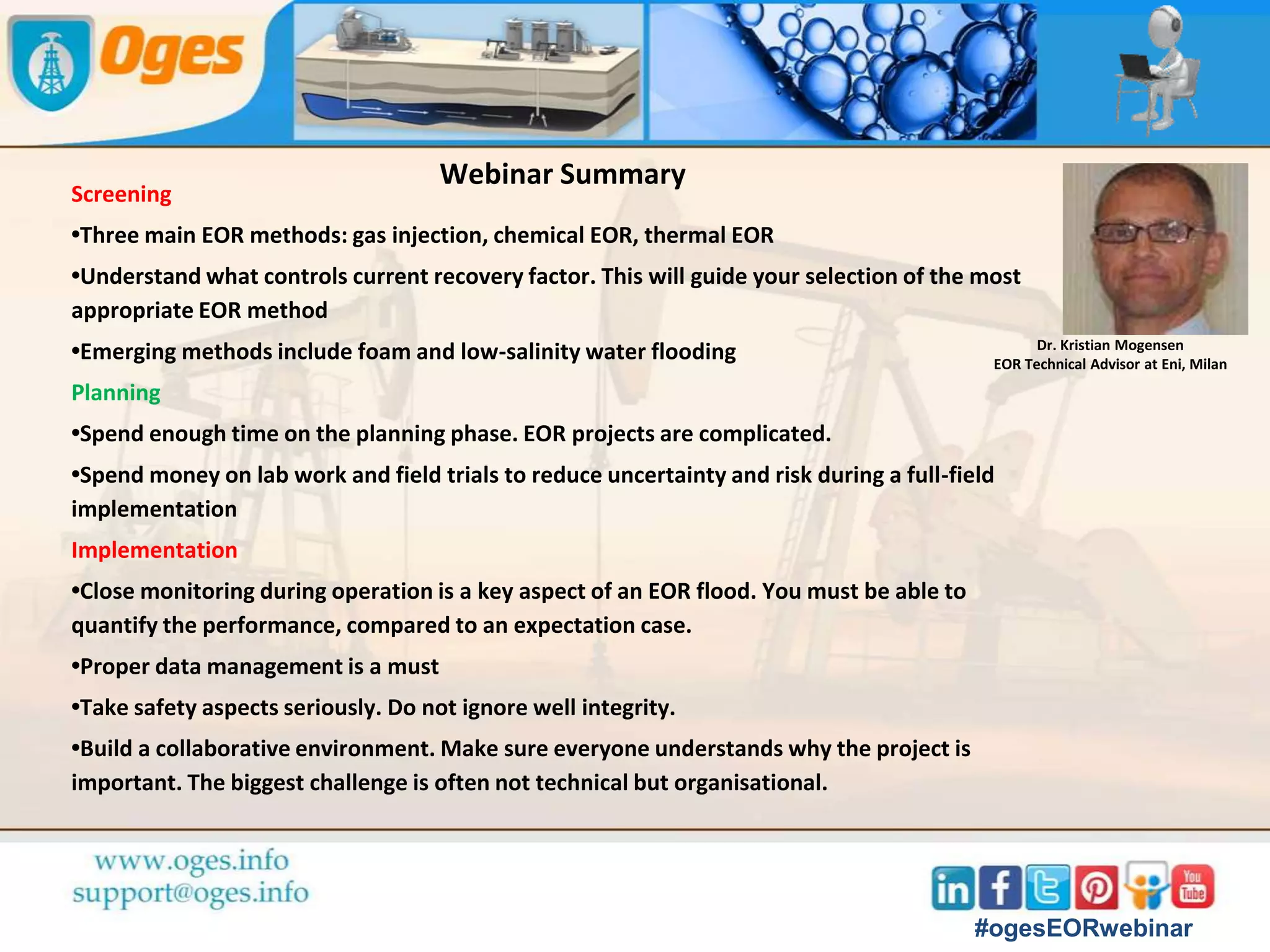

The document presents an overview of the OGES webinar focused on enhanced oil recovery (EOR) technologies and methods, featuring expert speakers and various EOR techniques. It outlines the key issues discussed, including monitoring techniques, challenges in completion, and recent advancements in EOR, such as polymer flooding and gas injection strategies. The content emphasizes the importance of collaboration among industry experts to optimize EOR processes and address associated technical challenges.