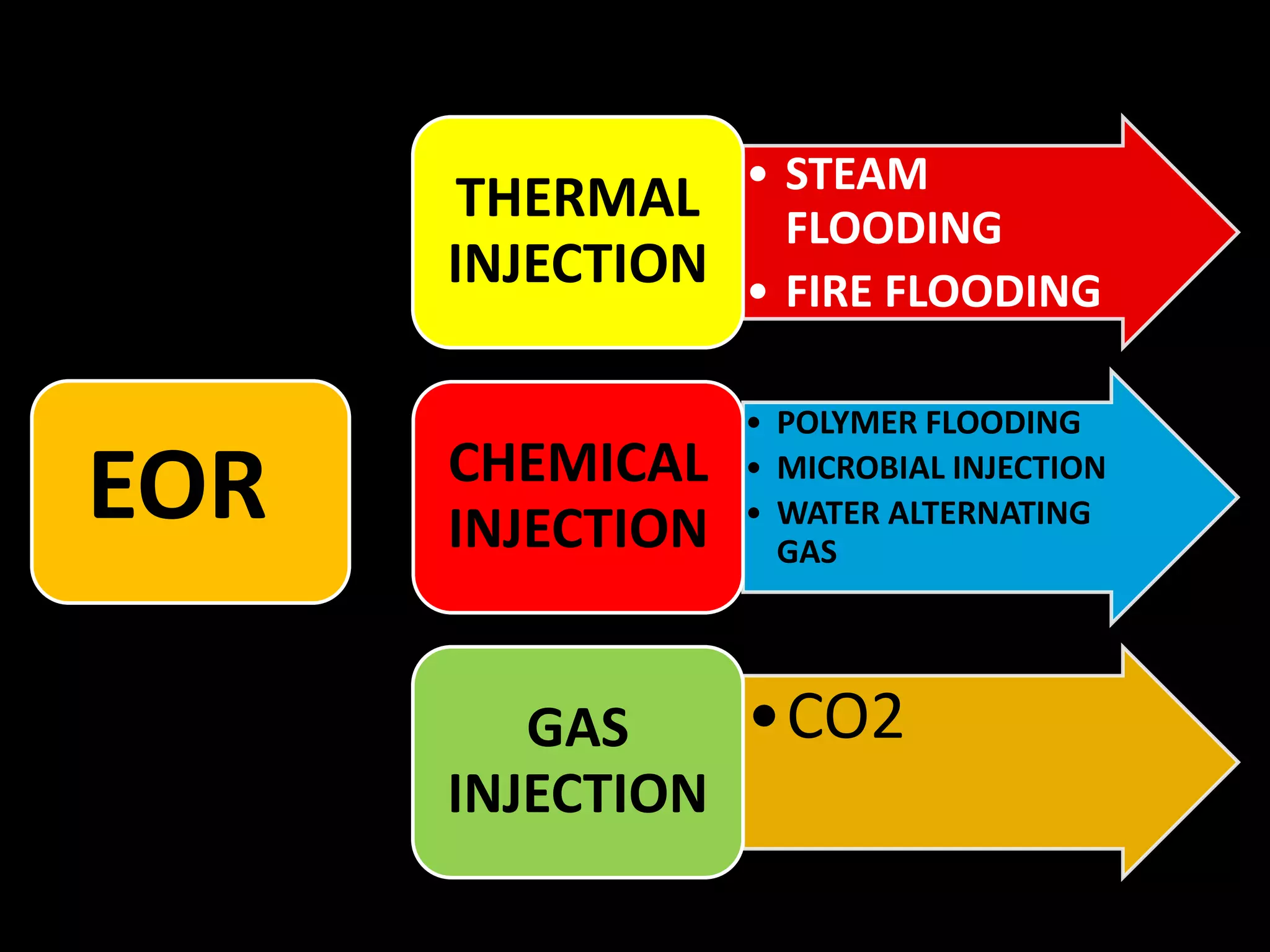

This presentation discusses enhanced oil recovery (EOR) techniques, which are used to extract additional oil from reservoirs beyond primary and secondary recovery. EOR methods include thermal injection like steam flooding, chemical injection using polymers or surfactants, and gas injection using carbon dioxide. Steam flooding is the most common thermal method, using steam to heat and liquefy thick crude oil. Chemical injection helps lower tensions and mobilize oil droplets. Gas injection, like CO2 flooding, dissolves gases in oil to lower its viscosity. While EOR extends oil production and is often economically viable, challenges include equipment corrosion and gas storage.