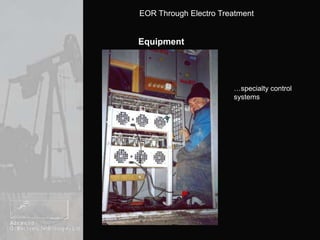

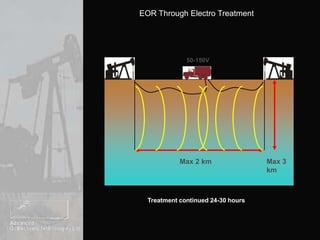

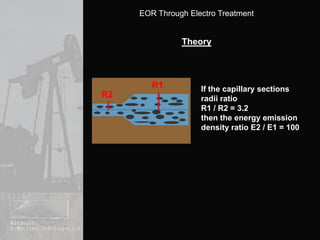

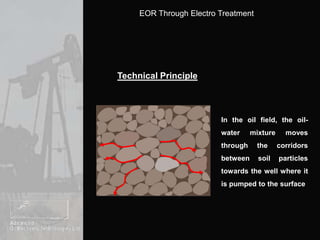

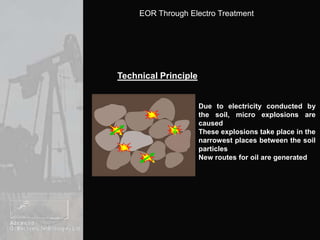

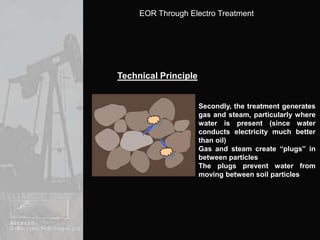

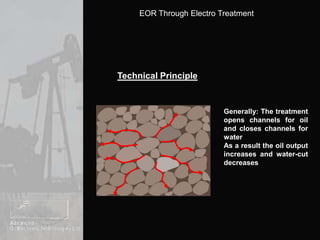

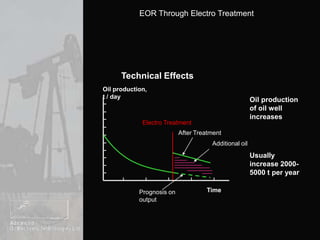

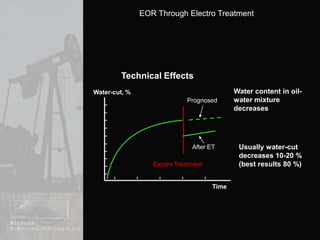

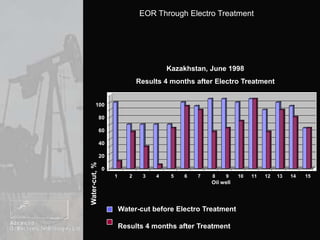

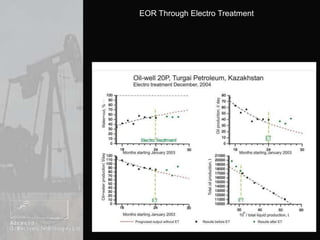

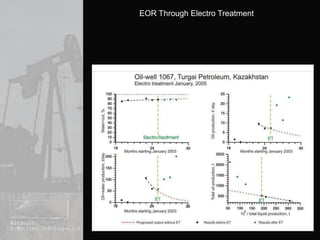

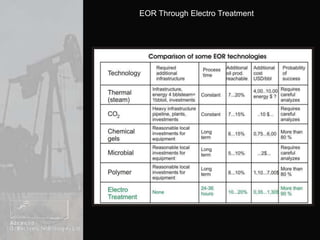

Electro-treatment is a new enhanced oil recovery method that uses electrical pulses to open new pathways for oil to flow out of aging wells. It requires portable, low-cost equipment and little energy. Initial treatments show increased oil production of 10-30% over the next 2-5 years, compared to other expensive EOR methods. The technology was developed in Russia and has been successfully tested on hundreds of wells in Russia and other countries. It works by using micro-explosions caused by the electrical pulses to break up tight spaces in the reservoir and allow more oil to flow through.

![PEAK OILThere is an on-going debate about the point where oil discovery and production will peak and begin to decline. New finds of oil have just not been able to keep up with demand - so the only resolve is to adapt technology to extend this peak and move from an exploration solution to an exploitation solution.Chevron estimates that the world consumes two barrels of oil for every one that is discovered. Enhanced Oil Recovery [EOR] is the adaptation of technology to recover more oil from aging wells with declining production. Typically this involves huge costs including tremendous amounts of infrastructure, huge energy uses (sometimes equal to or greater than the benefits), and time.Our proven technology involves a low cost portable treatment that requires no outside infrastructure and very little energy usage. A single treatment of 24 to 48 hours immediately shows increasing benefits for the following 2 to 5 years equal to or greater than competing EOR methods. Increased production is typically 10 to 30%, and at today’s price of crude oil, this equates to large dollar figures and a happy customer](https://image.slidesharecdn.com/enhancedoilrecovery-12869313100961-phpapp02/85/Enhanced-Oil-Recovery-2-320.jpg)