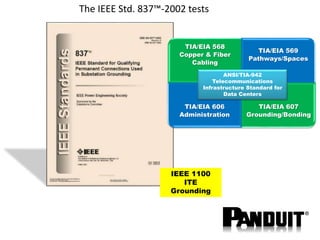

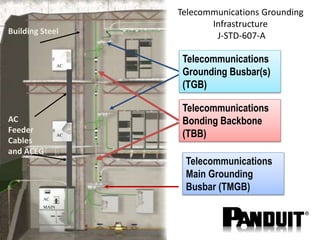

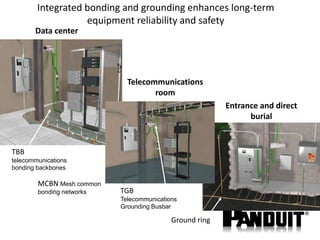

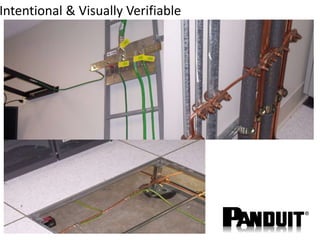

This document discusses grounding and bonding best practices for data centers and IT infrastructure. It covers the risks of improper grounding such as safety hazards, equipment failure from electrostatic discharge, and electrical noise. Standards for grounding and bonding like IEEE 837, TIA/EIA 607, and ANSI/TIA-942 are referenced. The document provides examples of electrostatic discharge voltages and how humidity affects ESD. Products and solutions for properly implementing grounding are also shown, like grounding busbars, bonding jumpers, and bonding hardware.