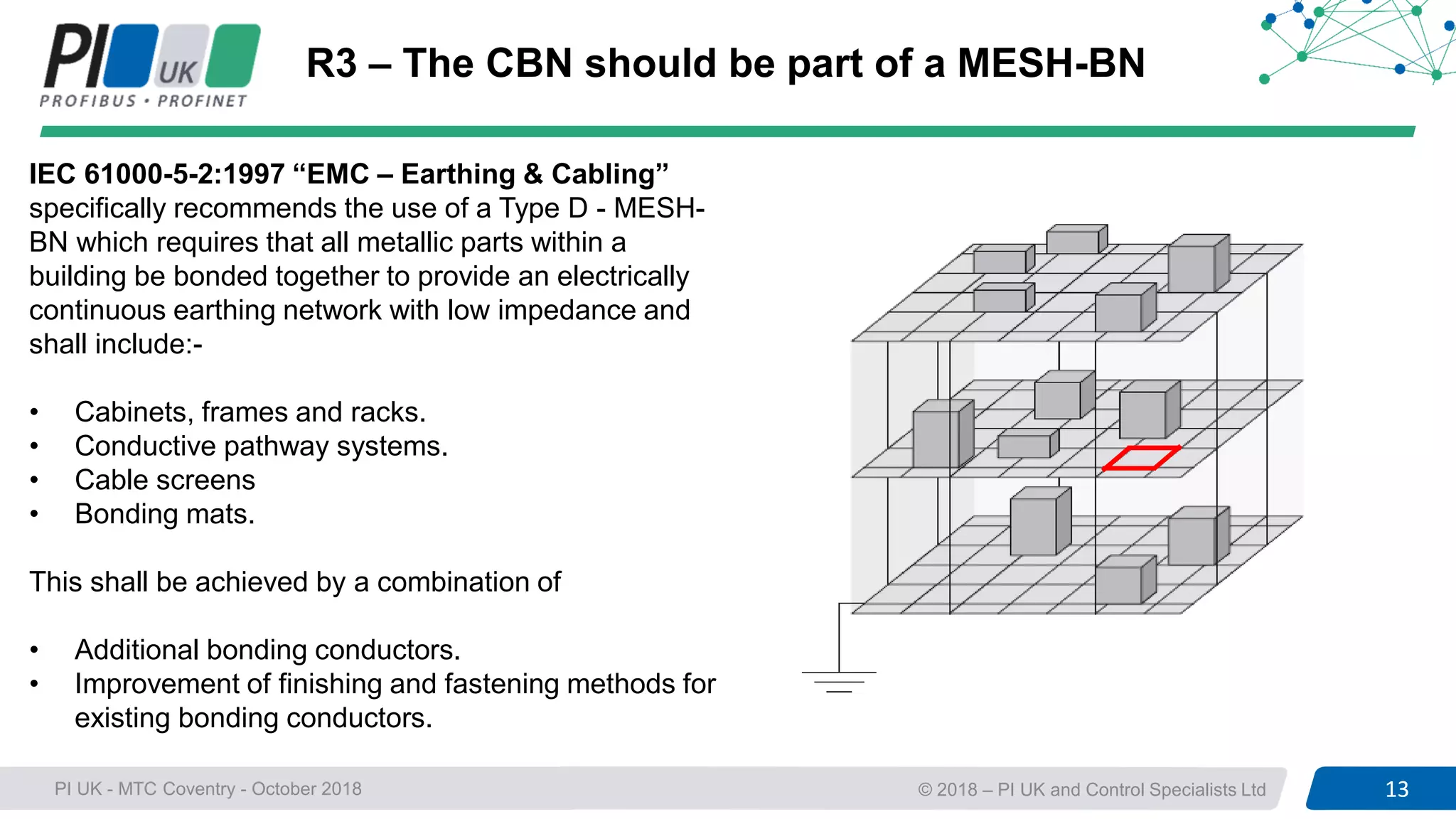

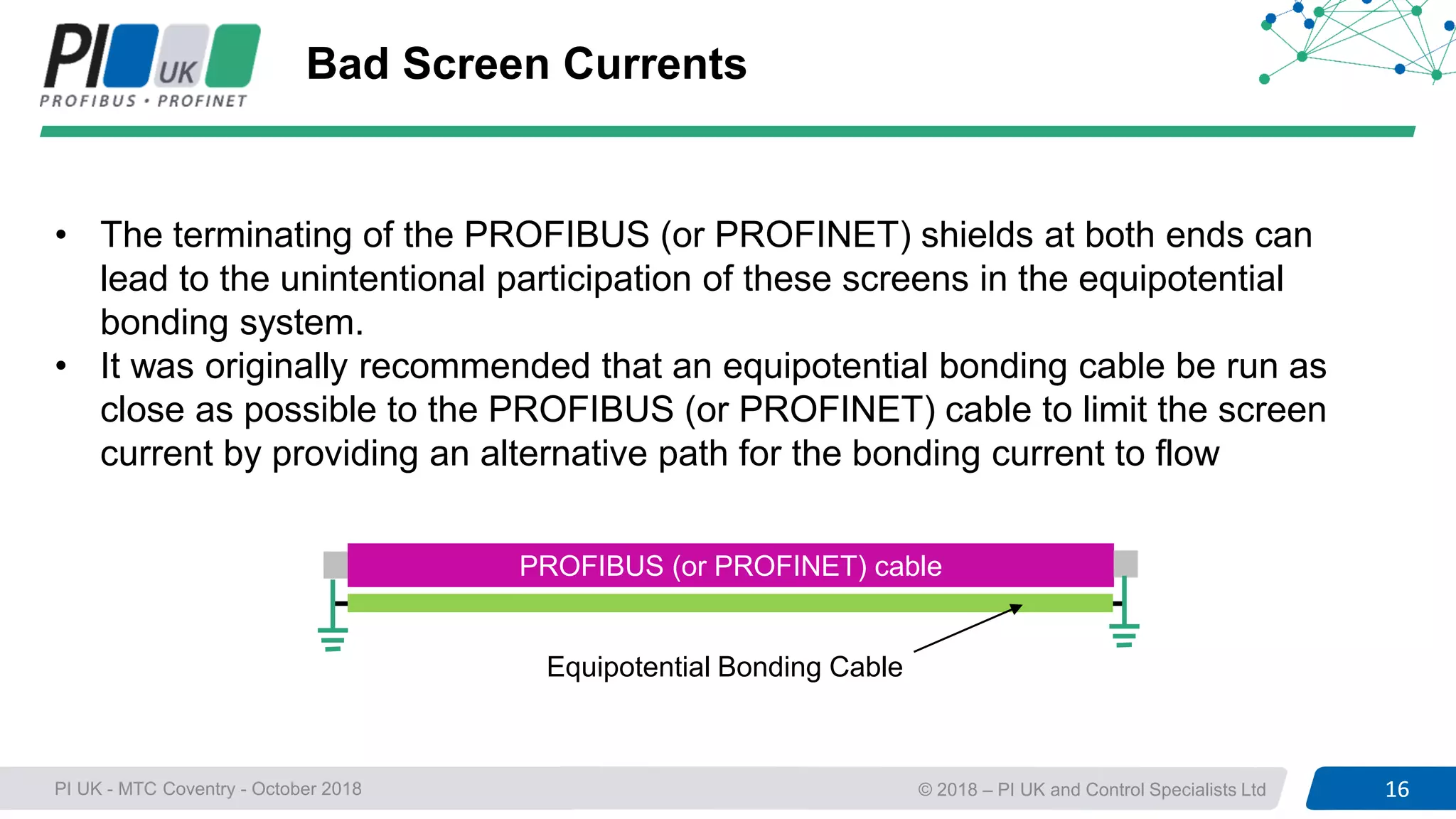

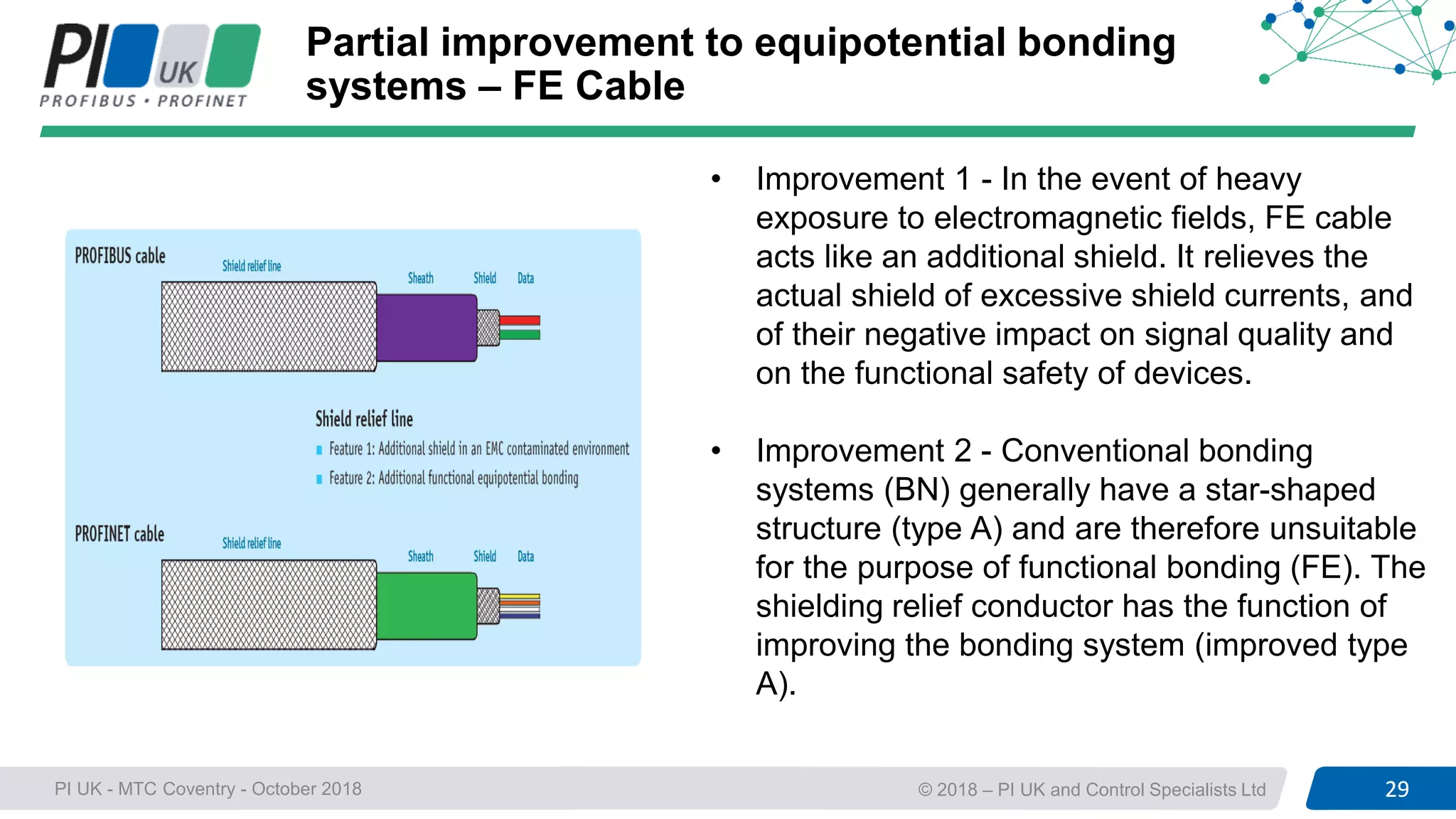

The document discusses the newly released guidelines on the functional bonding and shielding of Profibus and Profinet, presented by Peter Thomas, chairman of Control Specialists Ltd. It outlines six key recommendations for network designers, focusing on earthing practices, shielding termination, and improving equipotential bonding systems to mitigate electromagnetic interference (EMI). Additionally, the guidelines are intended for non-hazardous applications and emphasize a need for updated training on these practices.