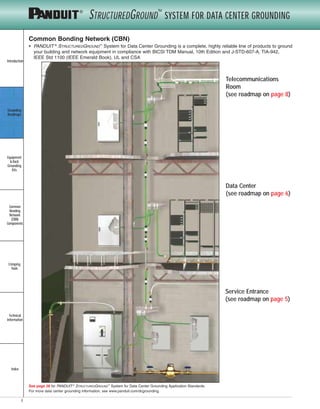

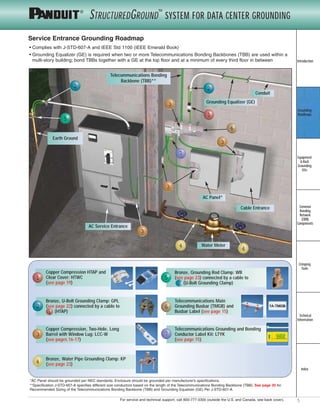

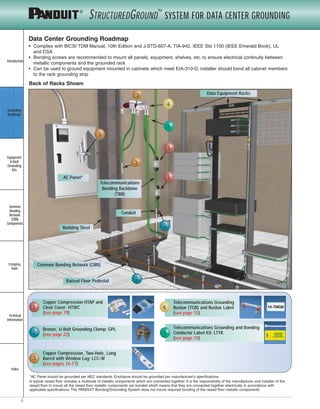

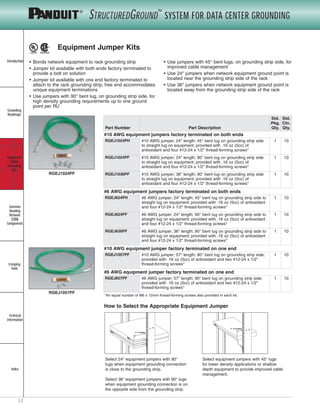

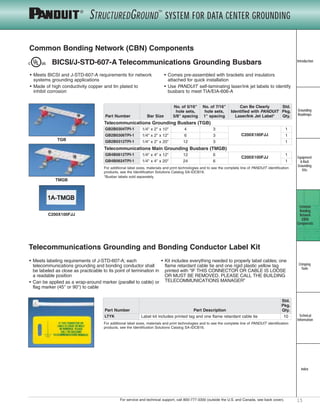

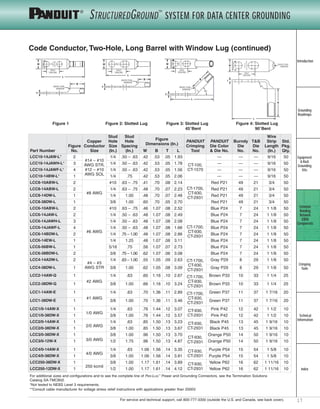

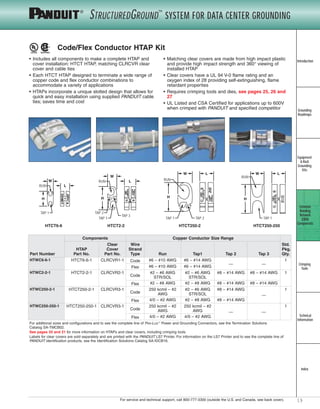

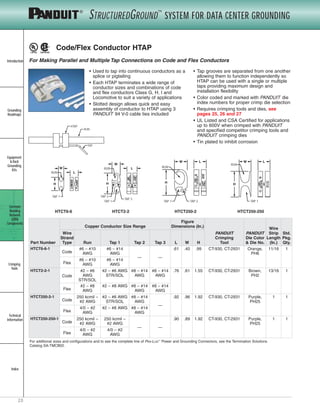

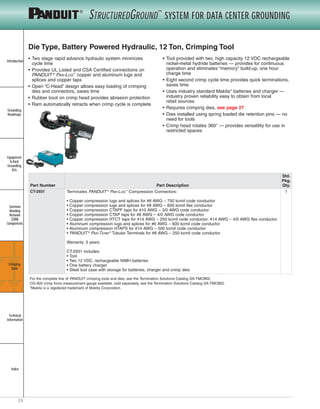

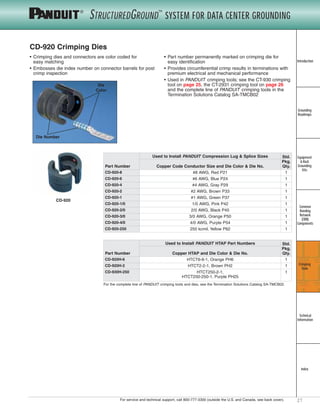

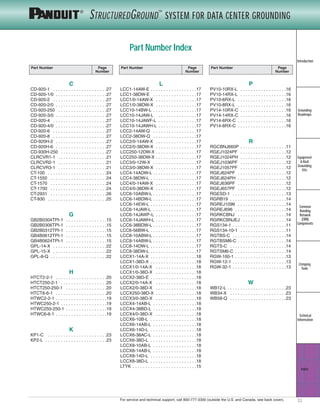

This document is a catalog for the STRUCTUREDGROUNDTM System for Data Center Grounding by PANDUIT. It provides an overview of the system and its components for properly grounding data centers, equipment racks, and telecommunications rooms. The catalog includes grounding roadmaps, technical specifications for products, and references industry standards for data center grounding.