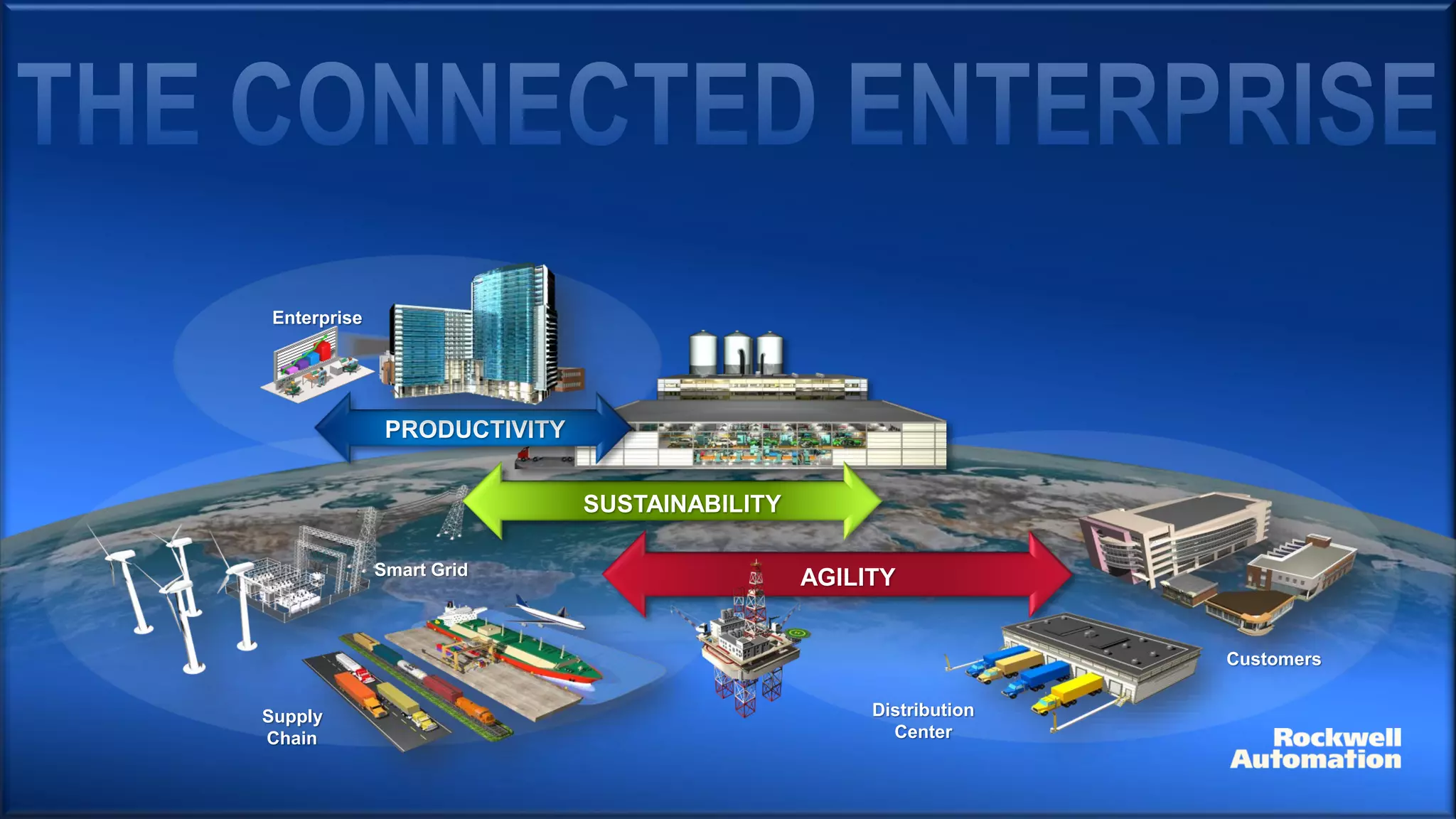

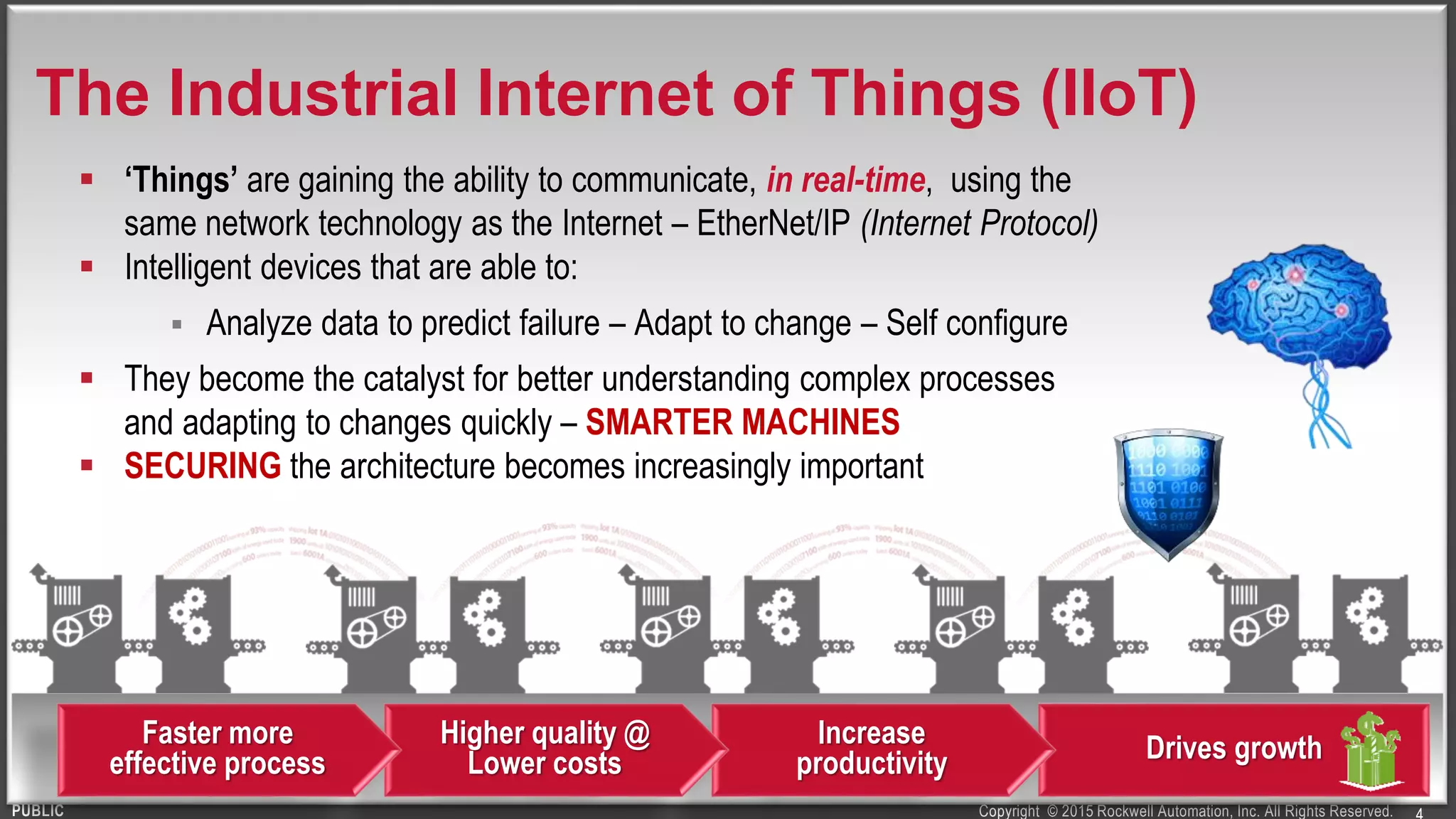

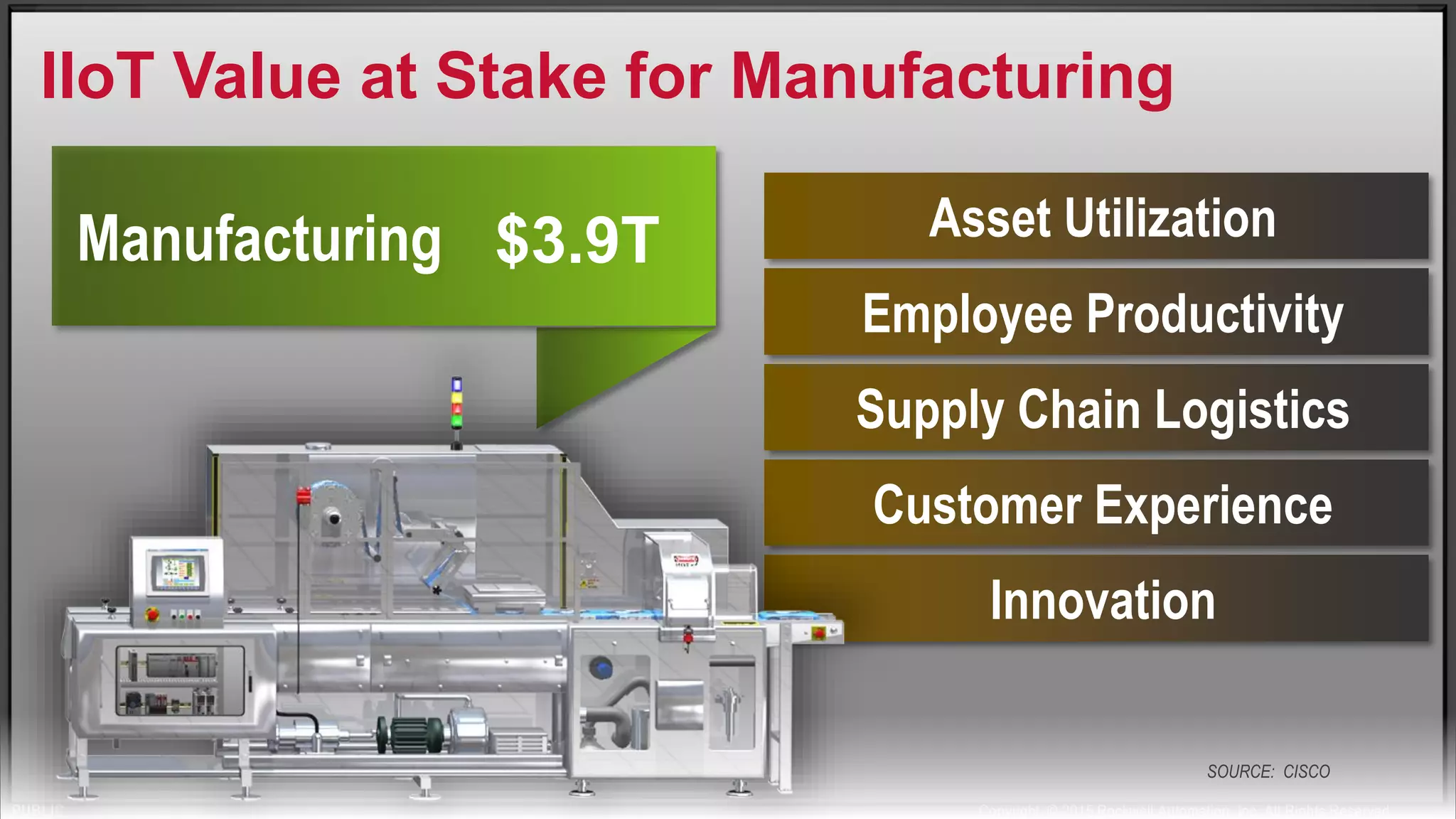

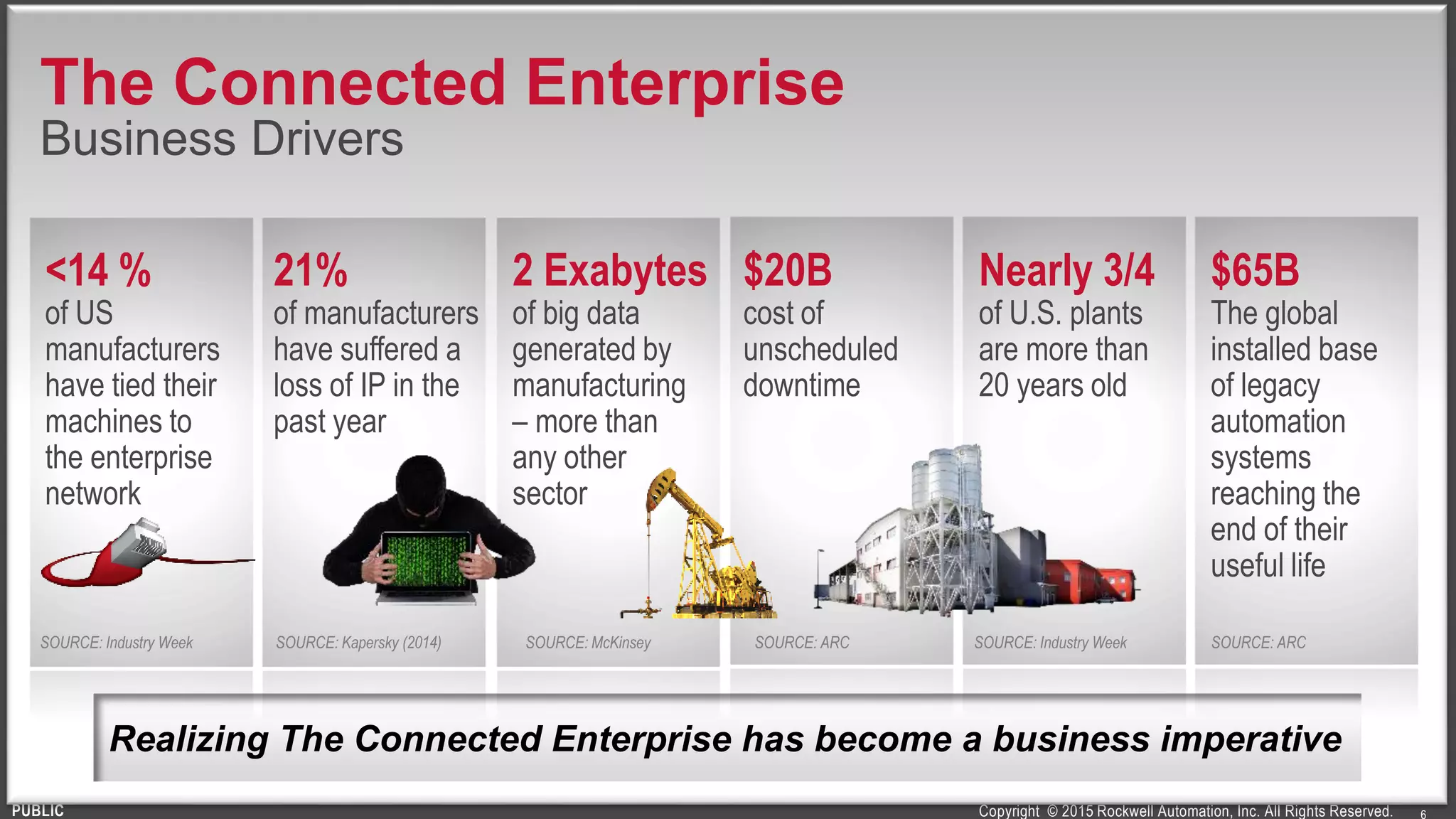

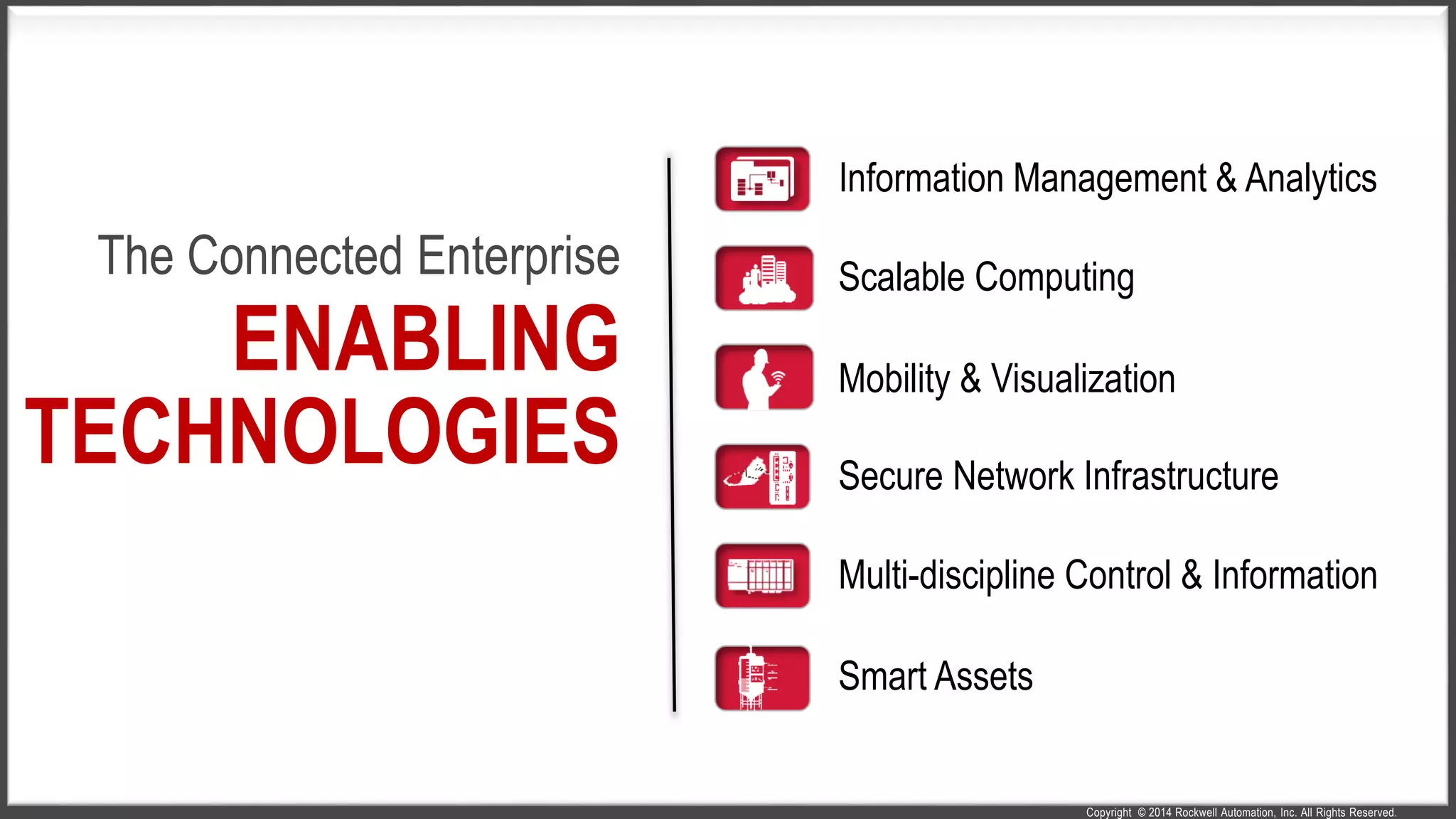

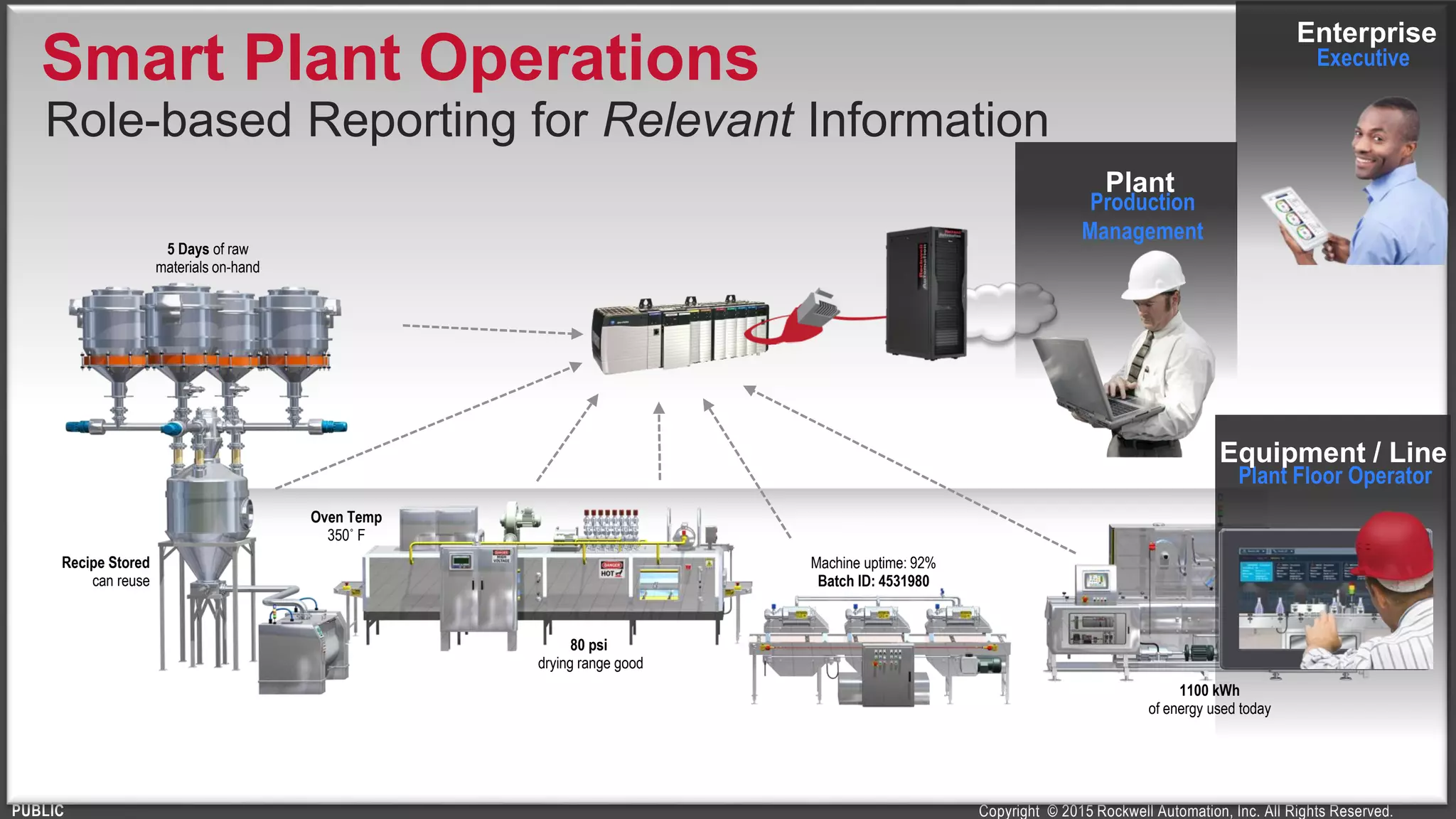

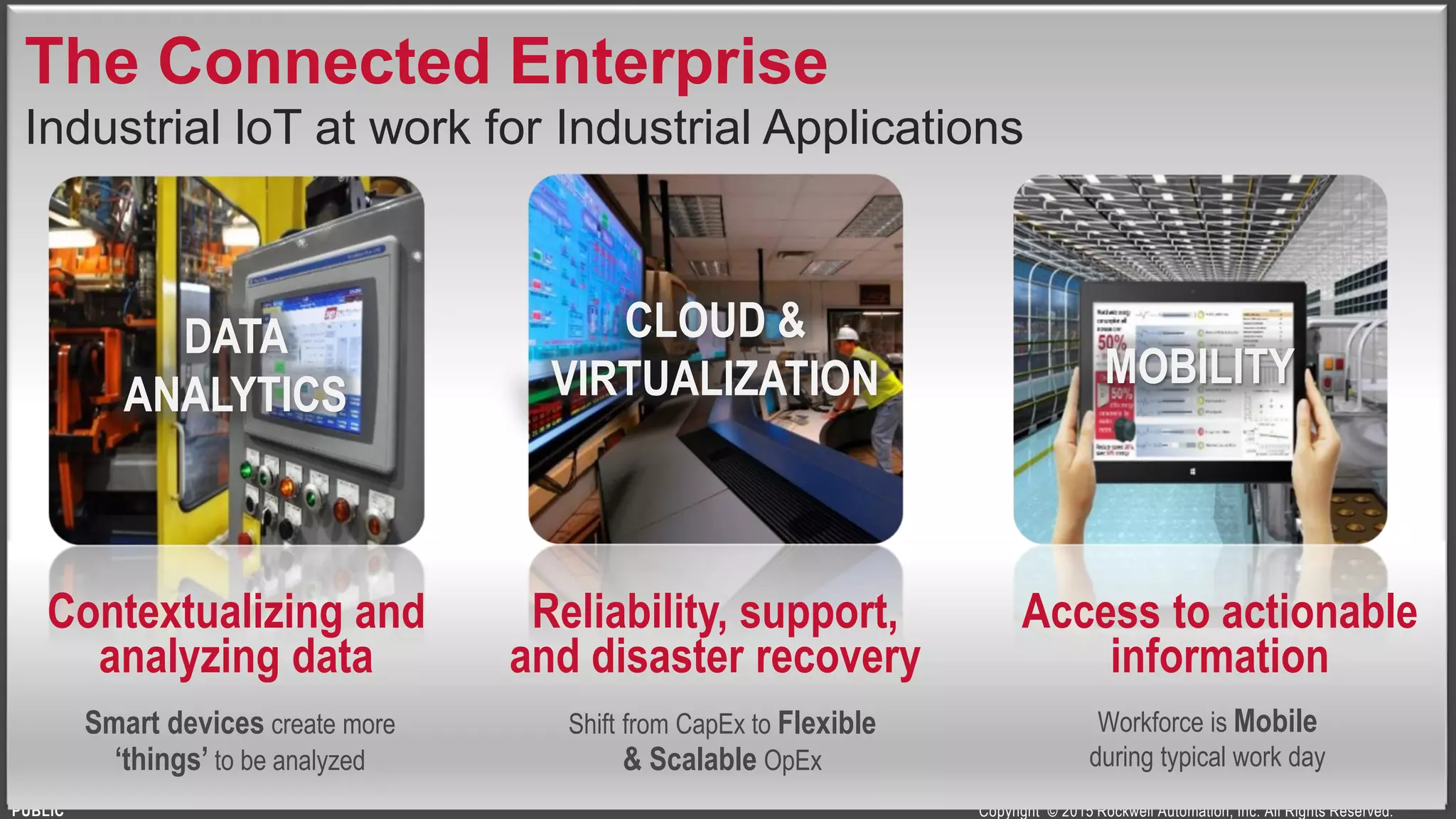

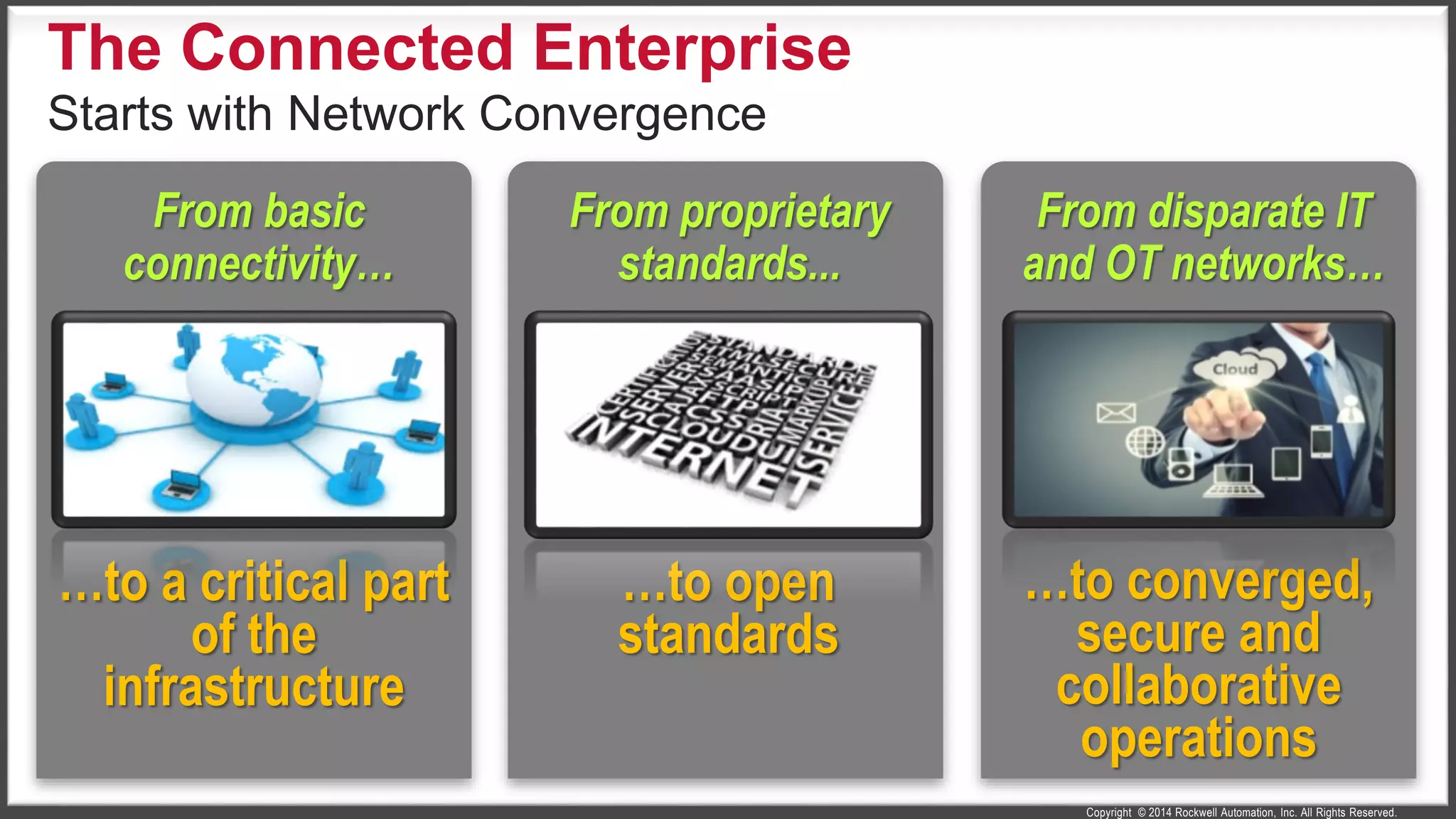

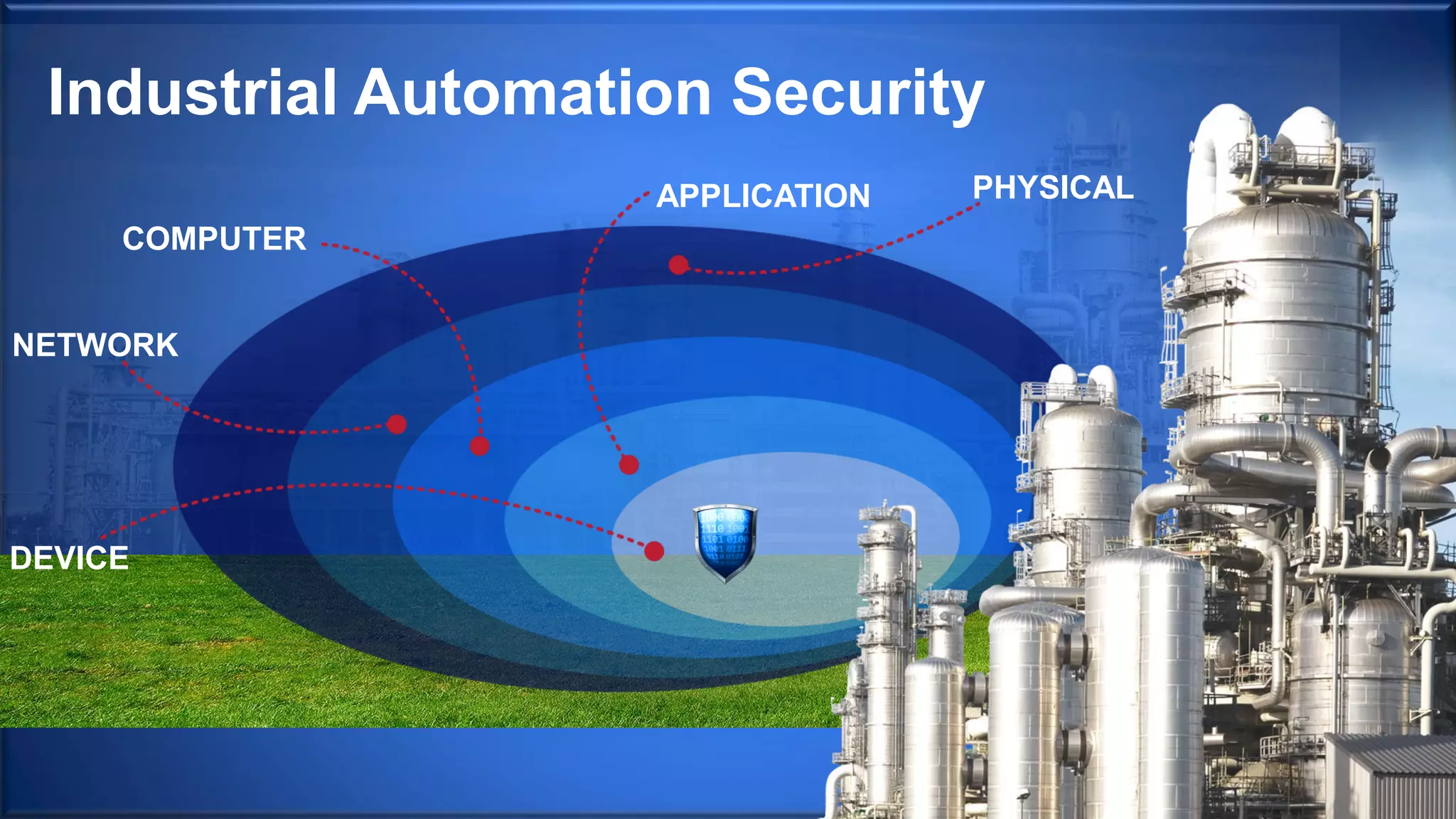

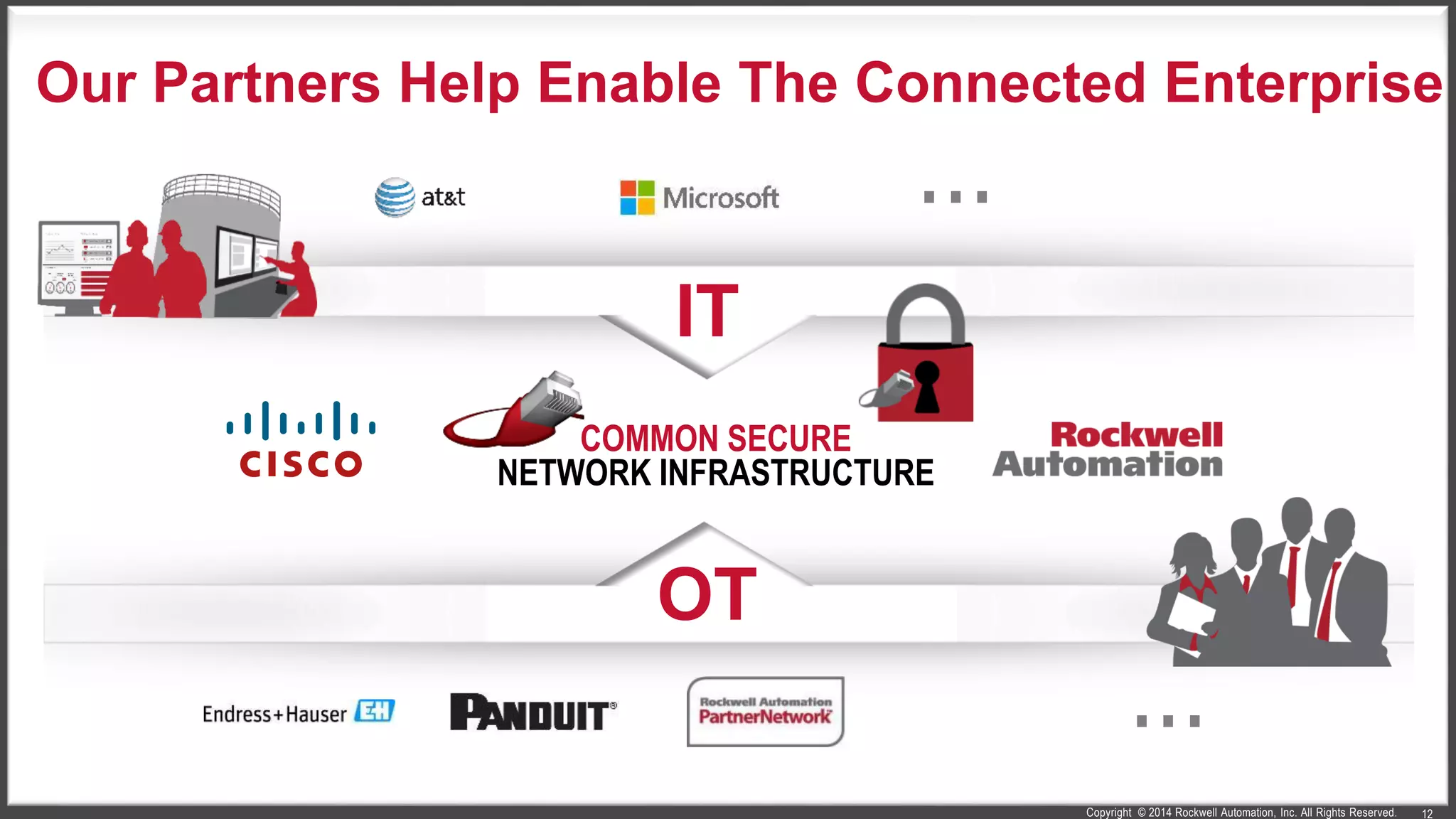

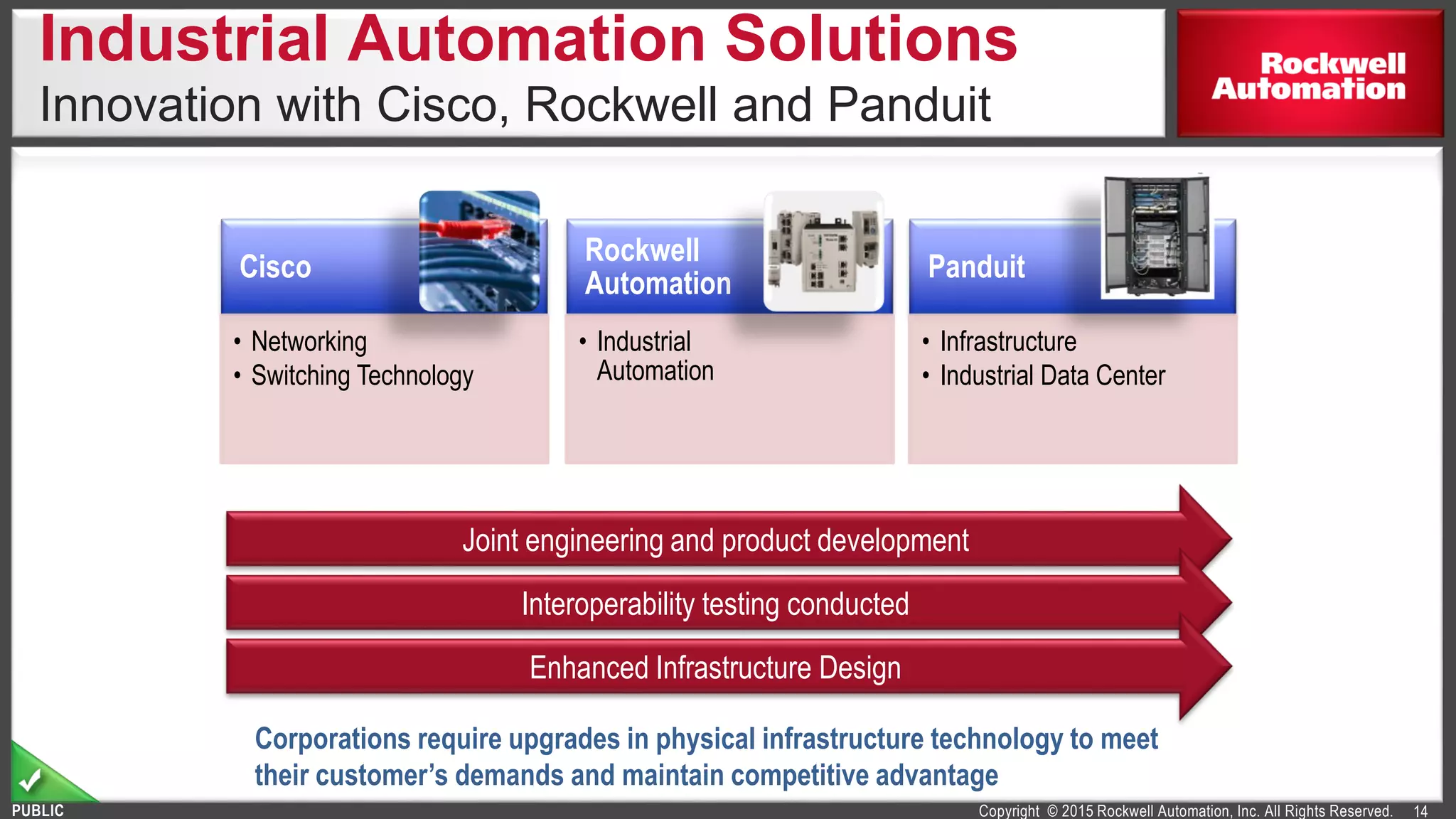

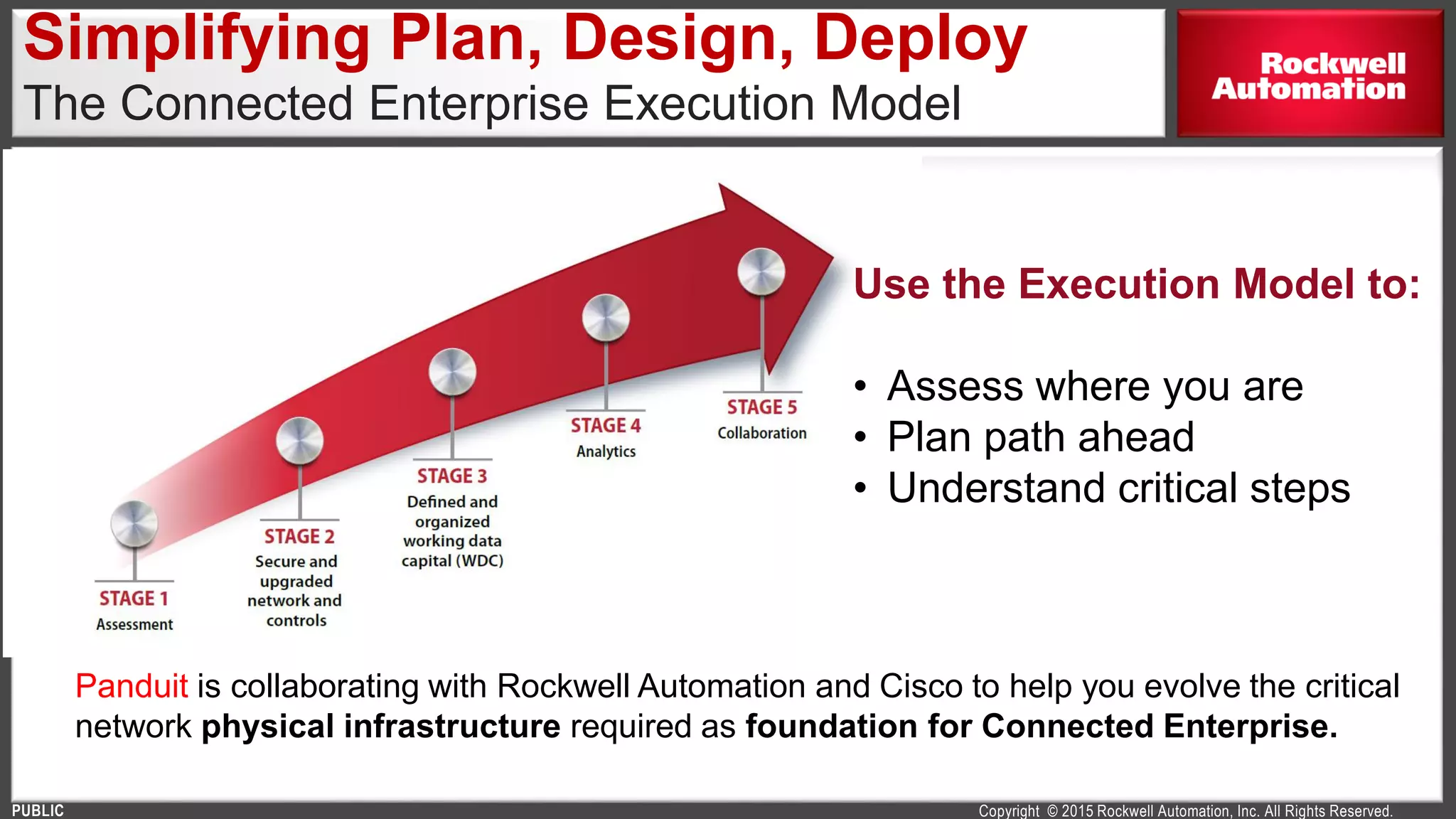

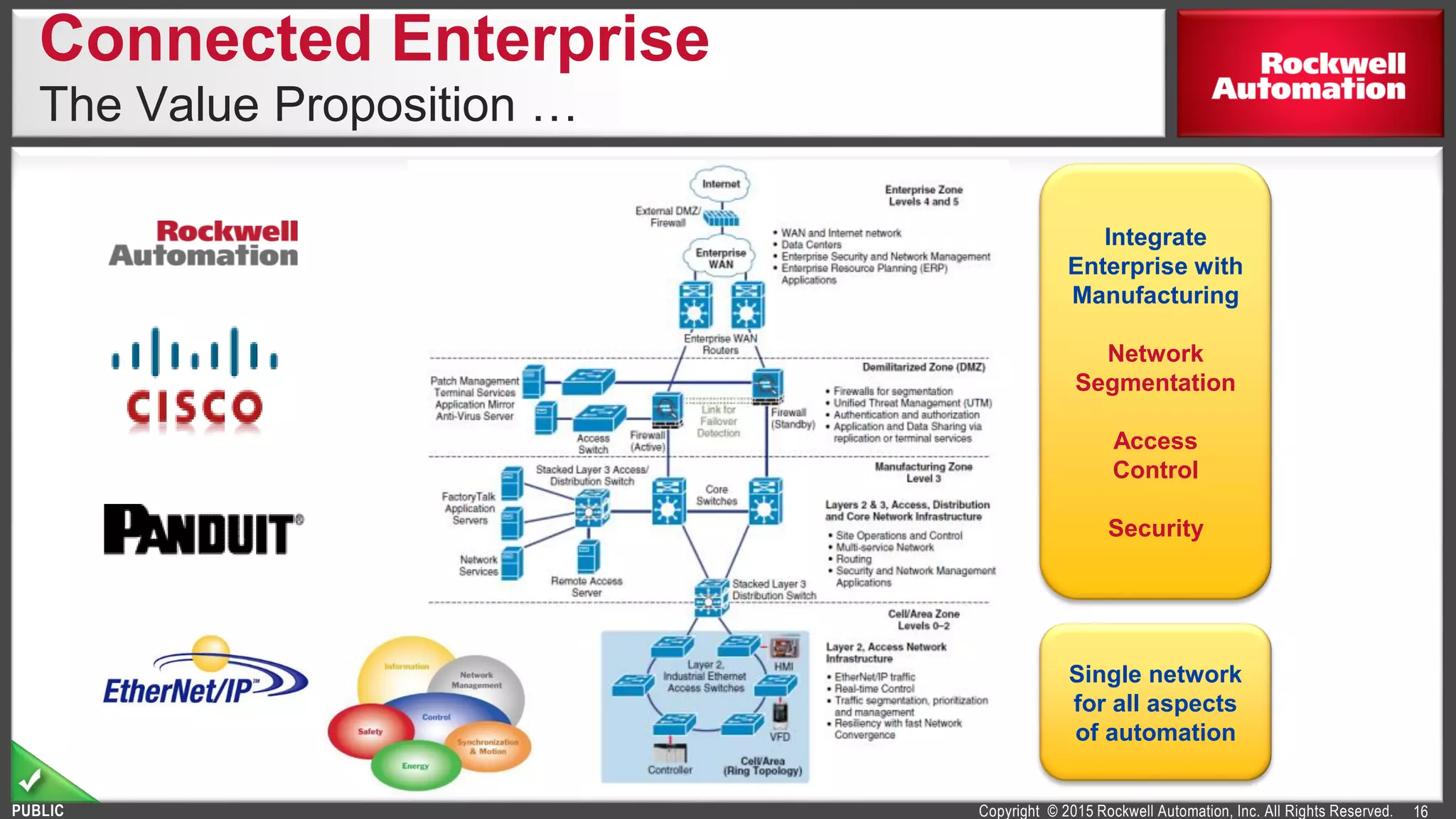

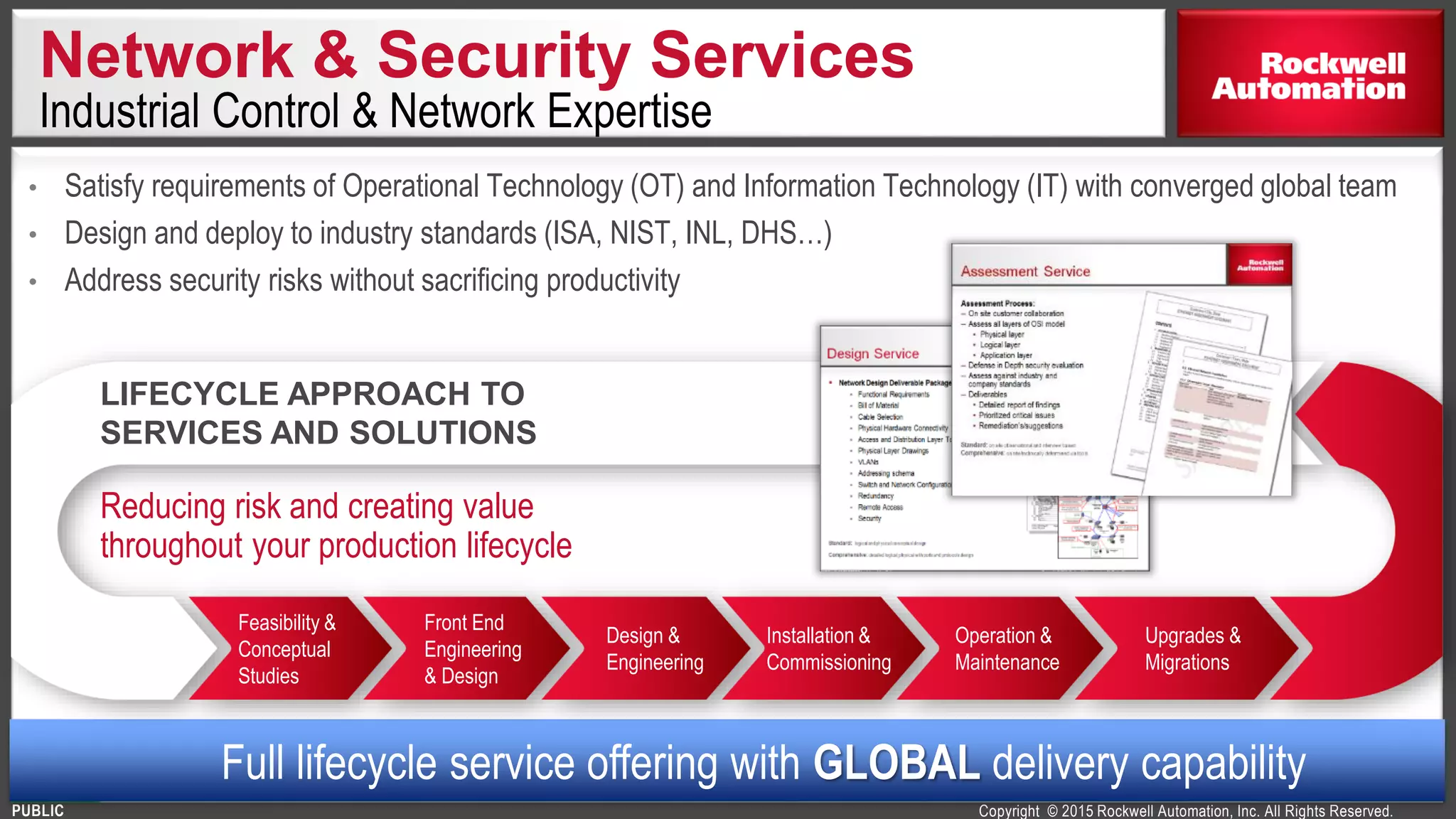

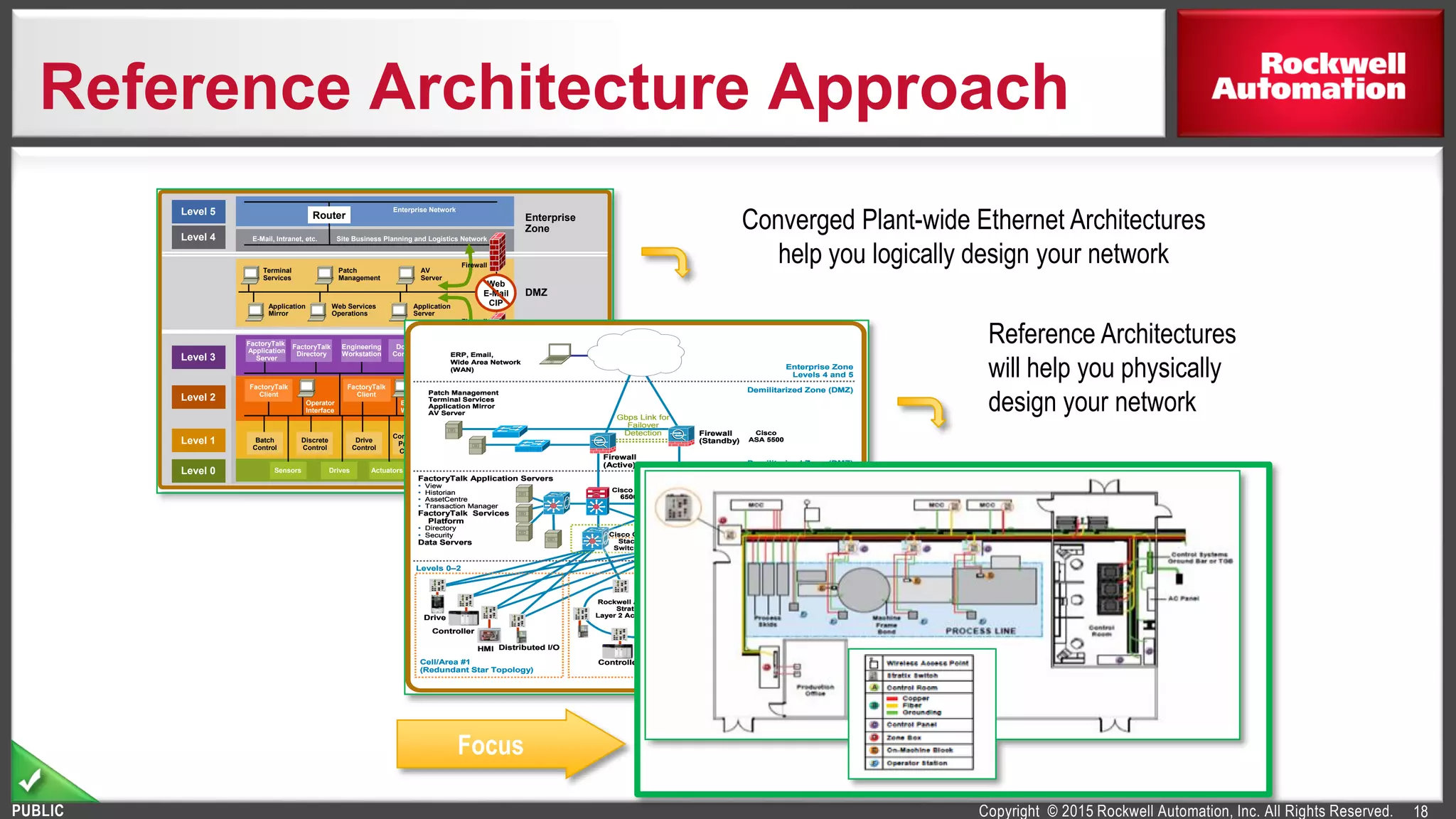

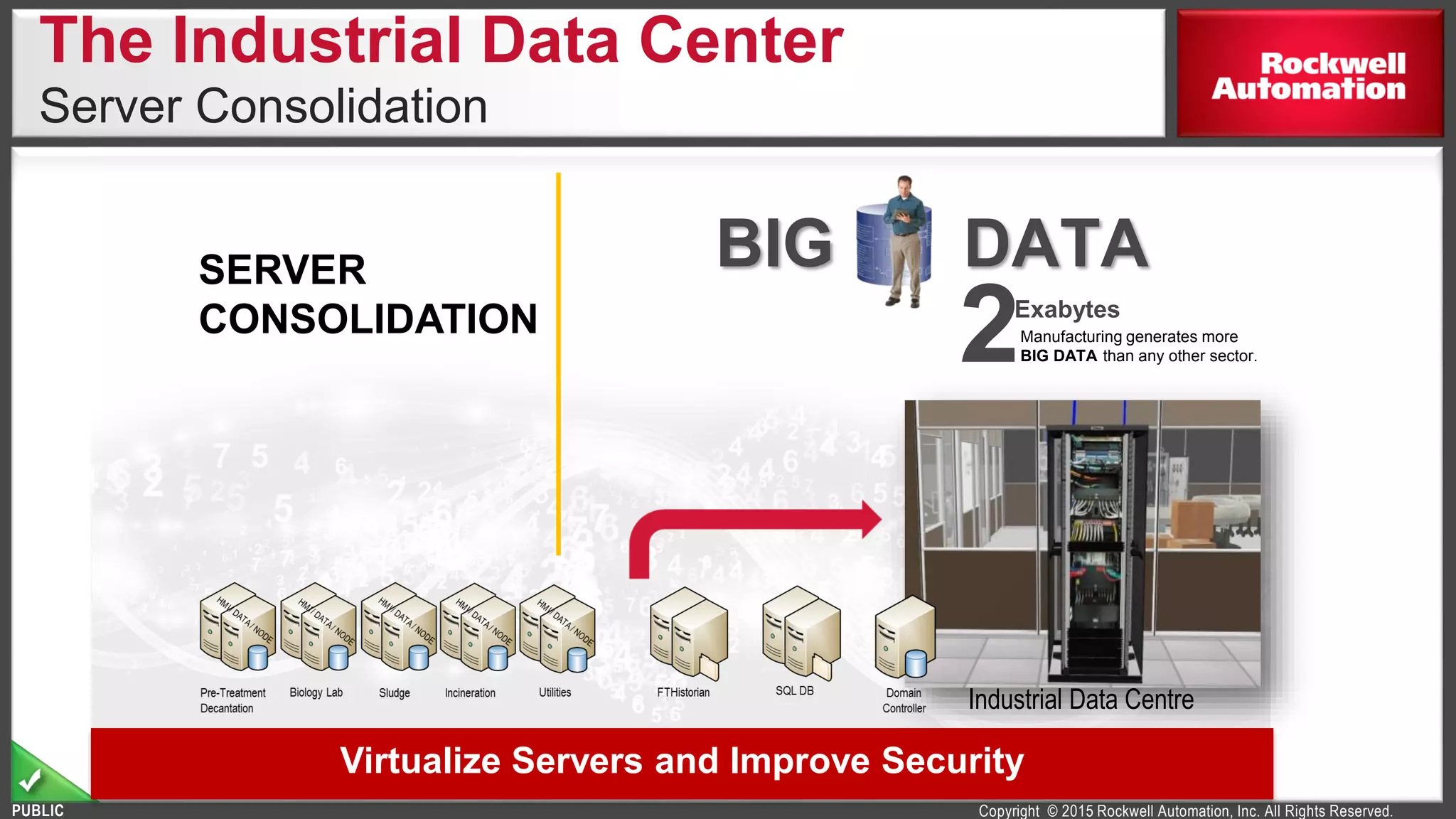

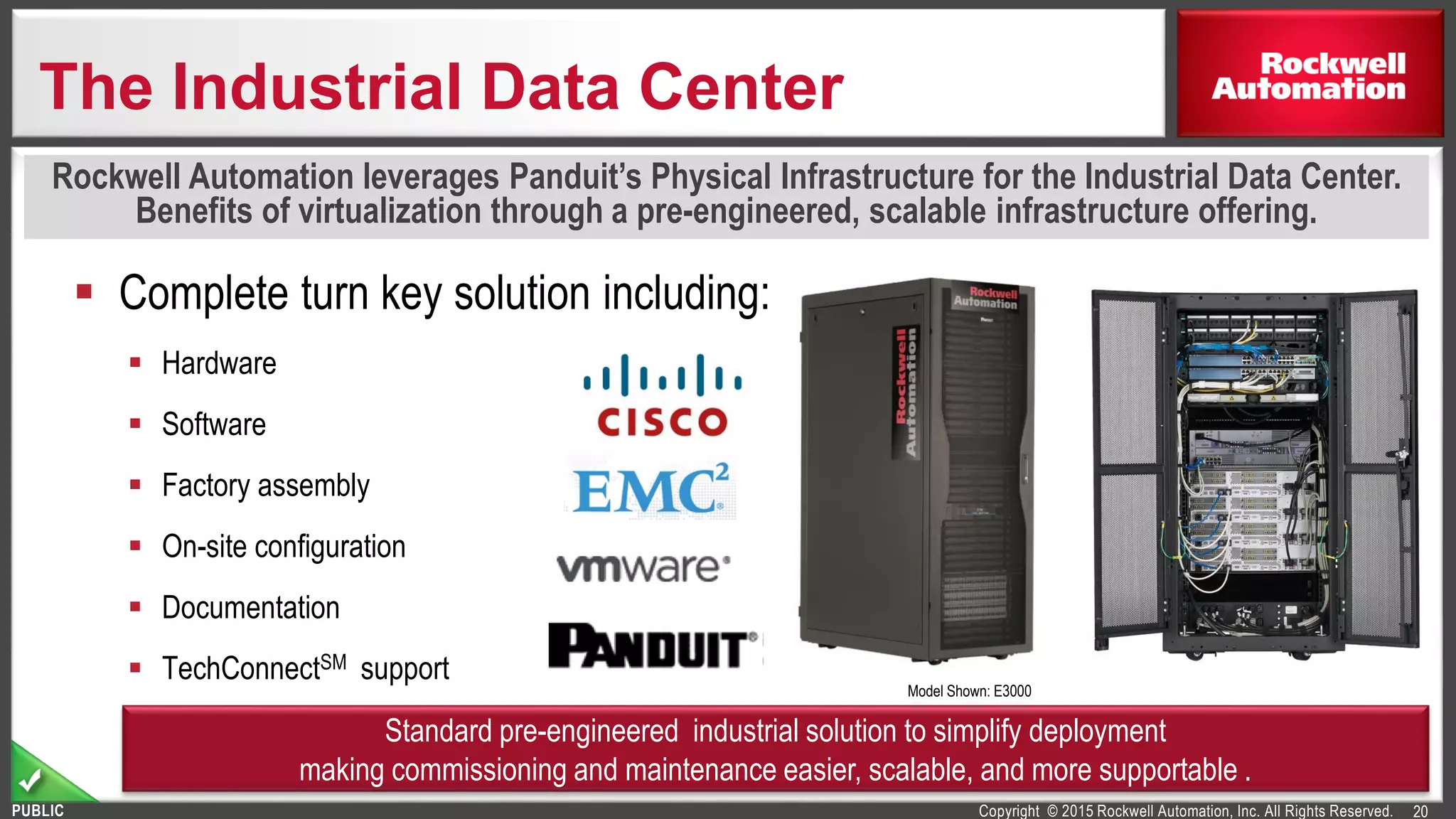

The document outlines Rockwell Automation's strategies for achieving operational excellence through IT/OT convergence, focusing on the industrial internet of things (IIoT) and connected enterprise solutions. It emphasizes the importance of a secure network infrastructure, data analytics, and the collaboration with partners like Panduit and Cisco to address manufacturing challenges and enhance efficiency. The content also highlights the need for businesses to integrate their networks and align their operations with modern technologies to maintain competitiveness.