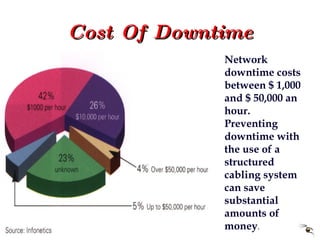

A structured cabling system allows for constant moves and changes to be performed by on-site personnel with growth and flexibility built into the cabling scheme. It supports and outlives most network components while only representing 5% of the total network investment. A structured cabling system allows moves, adds, and changes to occur quickly and cost-effectively, preventing downtime that can cost between $1,000 and $50,000 per hour.